Single Screw

● Pipe extrusion ● Sheet extrusion

● Profile extrusion ● Recycling extrusion

● Compounding extrusion ● Cable / wire extrusion

● Blown film / Lamination ● Colour liner / Coating extrusion

● Nonwoven fabric extrusion ● Monofilament / staple fibre extrusion

● Cast film ● Blow Moulding ● Injection Moulding

You Need Better Single Screw at Good Price

- Product Detail

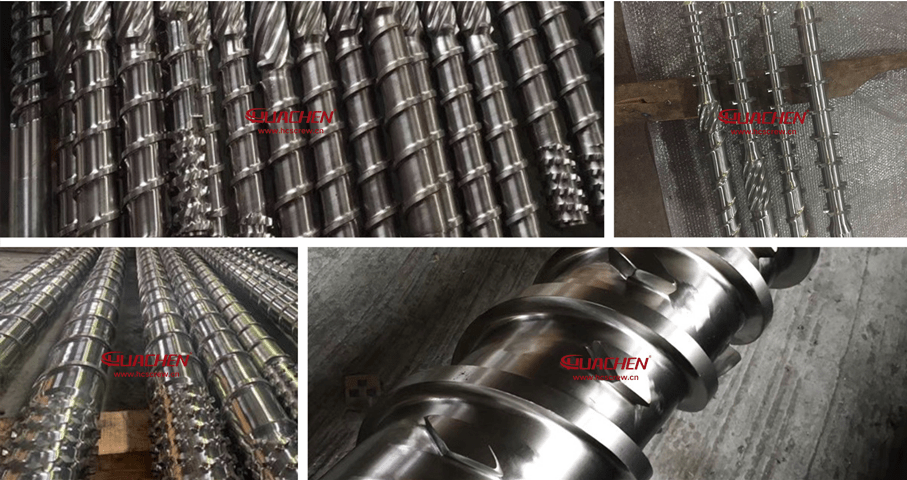

HUACHEN Screw has been a leading Single Screw manufacturer situated in Zhoushan Jintang since 2005. We design and manufacture precision screw barrels and accessories for plastic machinery and users. Our company has a mature working system for product quality control, production facilities, inspections, and testing with advanced processing equipment from home and abroad. Our company has also been successful in exporting and supplying screw barrels to customers around the world.

>> Learn More About Our Company

Single Screw

The design of the screw is crucial to increasing the efficiency of the machine, and at HUACHEN Screw we manufacture high-speed, high-production screws for the industries of PVC, PE, PP, PET, nylon, ABS, nonwoven fabric, monofilament and staple fibre.

We offer a wide range of single screws for

a. Pipe extrusion

b. Sheet extrusion

c. Profile extrusion

d. Recycling extrusion

e. Compounding extrusion

f. Cable/wire extrusion

g. Blown film/Lamination

h. Colour liner/Coating extrusion

I. Nonwoven fabric extrusion

j. Monofilament/staple fibre extrusion

k. Cast film

2. Blow Moulding

Various single screw designs are available

1. Standard screw

2. BM Screw

3. Barr screw

4. Barrier screw

5. Split flow screw

6. Maddock screw

7. Screw with mixer head

8. Screws for high speed extrusion with high efficiency

>> Learn more about common used single screw extrusion screw design

HUACHEN single screw features

1. Single screw diameter available: 25 mm to 300 mm

2. Single screw L/D ratio available: 15 to 40

3. Max. length: ≤10000 mm

4. Based materials: Premium 38CrMoAlA (UNS K24065, SACM645, 41CrAlMo7-10), tempered and nitrided.

5. Plasma nitriding surface hardness: HV 1000-1100

6. Plasma nitriding depth: ≥ 0.7 mm

7. Nitriding time: more than 120 hours

8. Nitriding fragility: less than Grade I.

9. Surface Roughness: Ra 0.4 μm

10. Screw Linearity: ≤ 0.015mm

11. Alloy depth: 2-4 mm

12. Alloy surface hardness: ≥ HRC 61

13. Chromium coating thickness: 0.03-0.05 mm

>> Learn more about our single screw parameter

The ultimate solution for abrasion and wear:

1. High strength alloy steel with tempered and nitride.

2. Overlay of nickel-based and molybdenum-based alloys on vulnerable screw parts with a thickness of 1 to 1.5 mm. Effectively provide 1.5 times longer service life.

3. hard chrome plating is an optional process.

Production time:

Within 15-28 days depending on the complexity of the part.

China manufactures 80% of the world’s screw barrels. Zhoushan produces 80% of China’s screw barrels. HUACHEN Screw manufactures screw barrels with 100% enthusiasm and intelligence in Zhoushan Jintang!

Call or mail us for more details and discussion about single screw technology!