Acceptance When You Get A New Screw And Barrel

Date:2022-5-26 Author:hcscrew

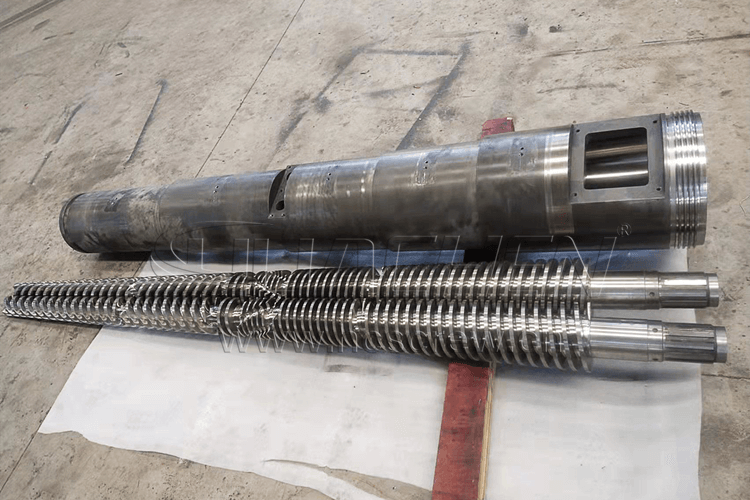

Upon receiving a newly manufactured screw barrel, how should we properly accept the screw barrel and install it on the extruder to start the machine? In this article, HUACHEN Screw Barrel, a leading manufacturer of extrusion screw barrels, discusses the screw barrel acceptance method in detail.

The process for accepting screws and barrels is divided into three parts. The first part is the acceptance of technical parameters, the second is the acceptance of appearance, and the third is the acceptance of installation. As part of installation acceptance, the screw barrel must be installed correctly and mounted; HUACHEN Screw Barrel will continue to update the detailed screw barrel installation and mounting methods.

01 Acceptance of the new customised screw barrel technical parameters

1. Review the screw and the barrel processing drawing (confirmed by both parties).

2. Review the dimensional accuracy of the screw and barrel; tempering hardness; nitriding hardness; brittleness; depth; surface roughness; metallographic analysis; and flaw detection report.

02 Acceptance of the new customised screw barrel appearance

1. Examine the screw and barrel for deformation, cracks, burrs, and other abnormalities.

2. Check that all parts of the screw barrel have intact internal threads.

3. Check whether there are processing defects and grain on the external surface of the screw and the inner surface of the barrel. The surface roughness should reach 0.08μm.

4. Check that the alloy layer on the surface of the screw prongs does not have shrinkage patterns and is combined with the substrate.

5. According to the machining drawings and the mounting holes, the screw dimensions are based on the screw length, the screw outside diameter, the screw rib width, the number of sections of the screw barrel, the center distance, flange, and sub-port. The screw dimensions are based on the machining drawings and the mounting holes.

6. Check the screw spline, barrel mounting holes, connector flanges, and sub-ports, as well as other mounting dimensions as per the machining drawings. Positioning dimensions of the joint and its flatness.

If a new barrel and screw are received, the methods above can be used to accept them. For more information about barrel and screw acceptance, please write to HUACHEN Screw Barrel Factory.

TAGS

HUACHEN Screw Barrel Recent Post

- High-performance PVC Screw Barrel for Efficient Extrusion

- Durable Conical Twin Screw Barrel for Precision PVC Pipe Production

- High-Speed Screw Barrel for Increased Extrusion Efficiency

- Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders

- High-Precision Parallel Twin Screw Barrel for Extrusion Excellence

- Top Quality Single Screw Barrels for Plastic Extrusion Applications

- High-quality Extruder Screw Barrel for Reliable Performance

- Efficient Plastic Extrusion Screw Barrel for Superior Output

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;