About us

- Company profile

- Technical Innovation

- Order service flow

- Screw barrel parameters

- SKD inlay bushing barrel

- Screw barrel process flow

- Exhibition

About us

- Address:NO.1 Liuhang Road, Xihou Industrial Zone, Jintang Town, Dinghai District, Zhoushan

- TEL:86-580-8052288

- FAX:86-580-8053878

- ZIPCODE:316031

- E-mail: info@hcscrew.cn

- URL:www.hcscrew.cn

Screw barrel parameters

Screw Barrel Materials and Manufacturing Process

Core Materials and Manufacturing Process

- Core Materials: Premium 38CrMoAlA (equivalent to UNS K24065, SACM645, and 41CrAlMo7-10), SKD11 (equivalent to D2), SKD61 (equivalent to H13).

- 2. Bimetallic Coating of Vulnerable Areas: Nickel-based alloys, cobalt-based alloys, molybdenum-based alloys, WC-Co hard alloys, ceramic alloys.

- 3. Tungsten Carbide Alloy Levels:

- –Level A: Containing tungsten of 40%

- –Level B: Containing tungsten of 25%

- –Level C: Containing tungsten of 9.5%

- 4. Alloy Base Material Using Centrifugal Casting Process: Non-tempered steel S38MnSIV.

Screw Barrel Surface Treatment

- 1. Hardness After Hardening and Tempering: HB 240-280

- 2. Depth of Nitriding Layer: 0.70 mm

- 3. Nitriding Duration: More than 120 hours

- 4. Surface Hardness of Nitrided Screw Barrel: HV≥1000

- 5. Brittleness of Nitrided Screw Barrel: Less than Grade I.

- 6. Surface Hardness After Grinding 0.20 mm: ≥ 760 (38CrMoALA).

- 7. Surface Roughness: Ra 0.4 μm

- 8. Screw Linearity: ≤ 0.015 mm

- 9. Hard Chrome Coating Thickness (Optional): 0.05-0.10 mm

- 10. Hard Chrome Coating Hardness (Optional): ≥ HV 950

Bimetallic Alloy Screw Barrel

- 1. Alloy Layers Formed by Centrifugal Casting Hardness: HRC 50-62

- 2. Thickness of Alloy Layers Formed by Centrifugal Casting: 1.50-3.00 mm on each side

- 3. Surface Hardness of Plasma-Coated Bimetallic Alloy Layer:

- -Nickel-based alloy: HRC 53-57

- -Nickel-base and tungsten carbide alloy: ≥ HRC 61.

- 4. Depth of Plasma-Coated Bimetallic Alloy Layer: 1-1.50 mm

Tool Steel Liner or Bush for Barrel Insert

- 1. Tool Steel Core Materials: SKD11 (equivalent to D2), SKD61 (equivalent to H13), tungsten carbide alloy steel.

- 2. Wear-Resistant Liner or Bush Surface Hardness: ≥ HRC 62

- 3. Wear-Resistant Liner or Bush Thickness: 6-10 mm

Suitable Plastics for the Screw Barrel Include:

- 1. Common Plastics

- 2. ABS, PA, PC, PE, HDPE, LDPE, LLDPE, PET, PP, PS, EVA, PU, PVC, UPVC, CPVC, WPC, SPC, etc.

- 3. PA + GF (glass fiber)

- 4. Flame-resistant reinforced plastics

- 5. Modified engineering plastics

- 6. All kinds of mixed recycled material (in scrap or granule), etc

Core Materials for Screws and Barrels Manufactured by HUACHEN

The nitride steel 38CrMoAlA is a high-quality nitride steel with excellent wear resistance, fatigue strength, and durability. 38CrMoAlA has high surface hardness, wear resistance, and fatigue strength after nitriding treatment, as well as strong heat and corrosion resistance. The screw and barrel of high-quality Chinese extruders are mostly made of 38CrMoAlA. The screw and barrel of various origins, 38CrMoAlA, and the common steel grades of each country have comparable properties and may be substituted for worldwide buyers.

Comparison of 38CrMoAlA, UNS K24065, SACM645, 41CrAlMo7-10 Compositions:

| Country | China | USA | Japan | Germany |

|---|---|---|---|---|

| Standard | GB/T3077 | SAE 6470 | JIS G4053 | DIN EN 10085 |

| Steel Grade | 38CrMoAlA | 135 Mod UNS K24065 | SACM645 (SACM1) | 1.8509 41CrAlMo7-10 |

| C | 0.35~0.42 | 0.38~0.43 | 0.40~0.50 | 0.38~0.45 |

| Si | 0.20~0.45 | 0.20~0.40 | 0.15~0.50 | ≤0.40 |

| Mn | 0.30~0.60 | 0.50~0.80 | ≤0.60 | 0.40~0.70 |

| F | ≤0.035 | ≤0.025 | ≤0.030 | ≤0.025 |

| S | ≤0.035 | ≤0.025 | 0.030 | ≤0.035 |

| Cr | 1.35~1.65 | 1.40~1.60 | 1.30~1.70 | 1.50~1.80 |

| Mo | 0.15~0.25 | 0.30~0.40 | 0.15~0.35 | 0.20~0.35 |

| Al | 0.70~1.10 | 0.95~1.30 | 0.70~1.20 | 0.80~1.20 |

Some screw and barrel producers use 40Cr material instead of 38CrMoAlA, which is difficult to tell apart in appearance but has a considerably different quality.

Heat Treatment of Core Materials for Screw Barrels

| Item | Temperature ℃ | Cooling | Hardness HRC |

|---|---|---|---|

| Annealing | 840~870 | Furnace cooling | ≤ 229 HB |

| Normalizing | 930~970 | Air-cooling | – |

| Quenching | 940 | Oil | >56 |

| Tempering | 150~200 | Water or oil | 51~56 |

| 300~400 | Water or oil | 45~51 | |

| 500~550 | Water or oil | 35~39 | |

| 600~650 | Water or oil | 28~31 |

Manufacturing Process for Nitrided Screw Barrels

The primary purpose of nitriding treatment on nitride steel is to increase its wear resistance. The hardness of 38CrMoAlA after nitriding may reach HV1000 or higher, and the hardening layer can reach 0.7mm or more. The nitriding screw barrel process generally includes:

Rough machining → Tempering → Finishing → Stress relief → Fine grinding → Nitriding → Fine grinding → Assembly

The screw barrel’s strength properties are ensured by these eight operations. However, some producers may skip the early tempering and stress relief processes. The product will be almost unnoticeable, but the effects on the barrel screw’s life will be significant. Furthermore, because all eight procedures take time to complete, a high-quality screw barrel needs sufficient production time.

Bimetallic Alloy Screw Barrel Manufacturing Process

Based on the screw barrel treated with nitriding, the screw barrel is treated with alloy spray welding inlay to effectively improve its service life, although this increases the cost.

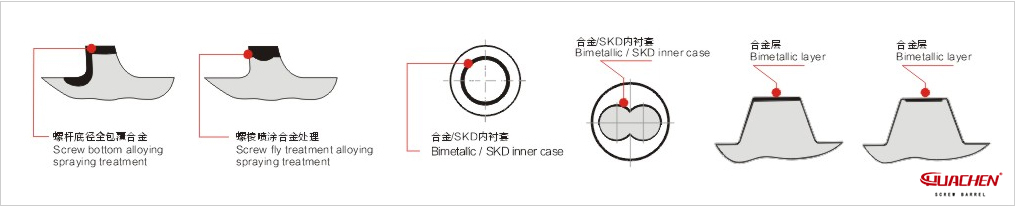

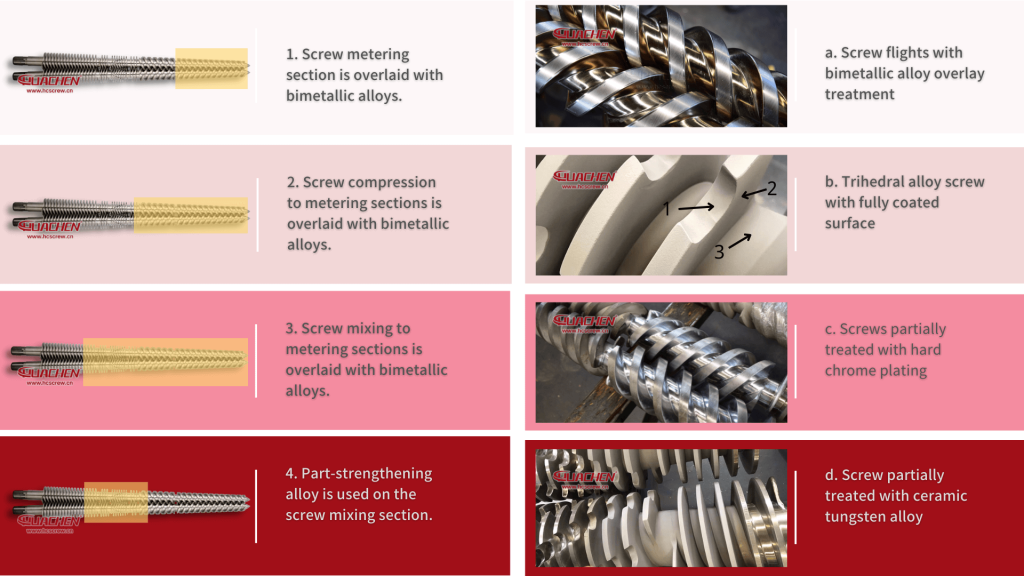

Bimetallic Alloy Screw Process

Bimetallic alloys are produced using high-quality composite alloy powders, such as nickel-based alloys, cobalt-based alloys, molybdenum-based alloys, WC-Co hard alloys, ceramic alloys, etc. Materials, ratios, and reinforcement areas are selected based on the material being processed.

The surface of the screw flights is grooved to approximately 2-4 mm and then inlaid with the wear-resistant alloy layer. HUACHEN Screw uses a self-developed composite alloy ratio and overlay treatment process, ensuring the screw and barrel have a uniform wear rate, performing well in high-filled and corrosive environments.

Position of the Bimetallic Alloy on the Screw

- 1. Surface coating of screws’ vulnerable areas with bimetallic alloys by plasma.

- 2. Three-sided alloy treatment process: screw flights, screw flight sides, and screw flight bottoms are coated with bimetallic alloys.

- 3. Chrome plating screw.

- 4. Ceramic coating alloy screw.

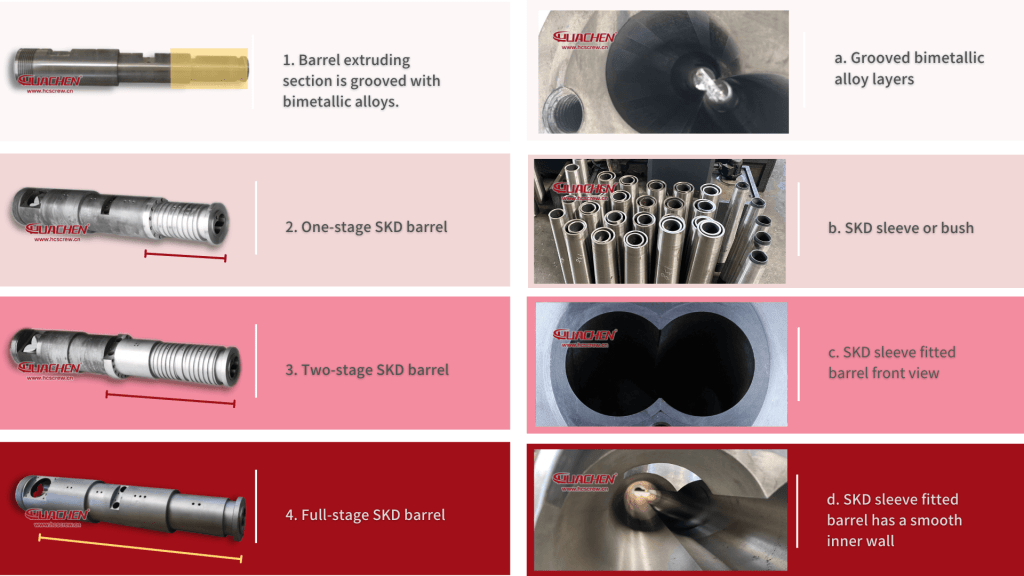

Bimetallic Alloy Barrel Process

Wear is most likely to occur in the extruding and feeding sections of the barrel wall. By using various bimetallic alloy processes, we have enhanced the wear resistance of these areas of the inner barrel. This solution extends the service life of the barrel walls by ensuring even wear. We choose the most suitable solution depending on the actual material to be processed.

- 1. grooved bimetallic layer process in the barrel bore extruding section.

- 2. centrifugal casting process into the barrel bore

- 3. SKD sleeve or bush fitted barrel technology.

Click here to see the actual results.