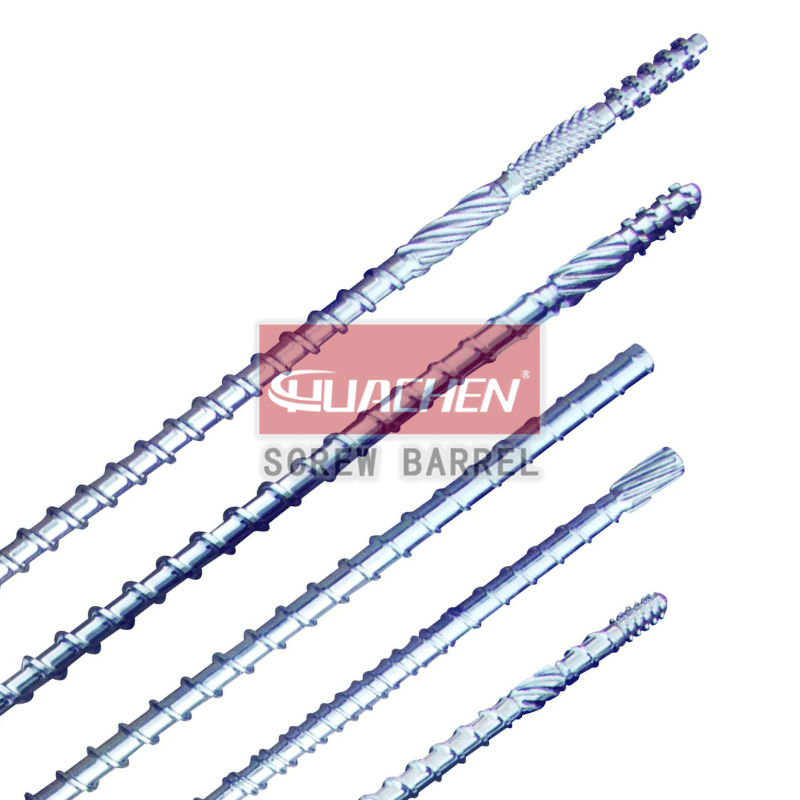

Cast PE Film CPE Film Making Extrusion Screw Barrel

● PE, LDPE, LLDPE, HDPE

● Min. Order (MOQ): 1 screw + 1 barrel

● Cast plastic film or sheet making

● Fresh raw materials. Recycled raw materials

● Anti-wear solution: Bimetallic barrel + bimetallic screw, nitriding barrel + bimetallic screw, nitriding screw barrel, chrome coating screw

You Need a Better Cast Film CPE Film Extruder Screw Barrel at Good Price!

- Product Detail

HUACHEN Screw has been a leading manufacturer of cast PE film CPE film making extrusion screw barrel in Zhoushan Jintang since 1993. As one of the leading companies in designing and processing plastic machinery replacement parts, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customized screw barrels. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn more about our company

Cast PE Film CPE Film Making Extrusion Screw Barrel

In the production of CPE cast film, LDPE, LLDPE, and HDPE are commonly used, but the high viscosity of PE makes it difficult to extrude. Screws are a major component whose design and construction are very critical.

1. A new high speed screw barrel optimized for processing PE cast films with a low melting point and a high viscosity. The screw has a new combined high speed screw structure that increases the shear force. The barrel With a forced feeding system, the high capacity grooved feeding barrel can get a low viscosity melt and increase speed.

2. The screw is designed with a small diameter, an L/D ratio of 27-33, and a low compression ratio. A high-polish surface is applied to the screw surface to make the PE fluid conveying channel as short as possible. By doing this, you’ll get a stable pressure of PE melt to the mould inlet in the next step after melting.

3. The screw barrel is made of premium quality alloy steel 38CrMoAlA, which is tempered, precision machined and nitrided to provide superior hardness and corrosion resistance. All screw barrel sets are machined on a high-precision CNC screw milling machine, which ensures a high degree of consistency in extrusion performance.

4. Screw and barrel structure ensures uniform melt plasticisation, stable speed, and precise temperature control for cast film quality.

5. Screw barrels are easy to install and fit most models. In case you’re not sure of your screw barrel design, you can provide assembly information to our engineers.

Application

Cast plastic film extrusion. Cast PE film, CPE film manufacturing.

CPE film lamination film machine.

Parameters

1. Single screw diameter available: 45 mm to 180 mm

2. Single screw L/D ratio available: 27 to 33

3. Screw max. length: ≤10000 mm

4. Barrel max. out diameter: ≤350 mm

5. Based materials: Premium 38CrMoAlA

6. Plasma nitriding surface hardness: HV 1000-1100

7. Plasma nitriding depth: ≥ 0.7 mm

9. Nitriding fragility: less than Grade I.

11. Surface Roughness: Ra 0.4 μm

12. Screw Linearity: ≤ 0.015mm

13. Alloy depth: 4-6 mm

14. Alloy surface hardness: ≥ HRC 61

>>Learn more about our cast PE film CPE film making extrusion screw barrel parameters

The ultimate solution for abrasion and wear

Level 3: bimetallic barrel and bimetallic screw;

Level 2: nitrided barrel and bimetallic screw;

Level 1: nitrided barrel and nitrided screws;

Hard chrome coating screw is an optional process.

Barrel with centrifugal casting process is an optional process.

Production time

Complete set of cast PE film CPE film making extrusion screw barrel within 20-30 days depending on the complexity of the part.

You can get creative with our wide range of products at reasonable prices. We can produce screws and barrels that are suitable for high speeds and pressures using the blown film extrusion machine and various additives. It’s the China Original Factory for soft PVC film blown film screw barrels. If you have any questions, please feel free to contact us.