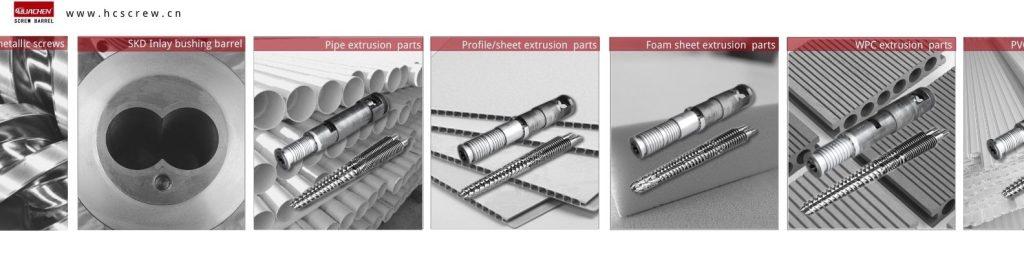

Conical Twin Screw Barrel

● Pipe extrusion ● Sheet extrusion

● Profile extrusion ● Compounding extrusion

● PVC / UPVC / RPVC / CPVC / WPC / SPC / HDPE

● Filler percentage with 0-100%, 100-200%, 200-300%, and greater than 300%

You Need Better Conical Twin Screw Barrel at Good Price!

- Product Detail

HUACHEN Screw Manufacturer offers premium conical twin screw barrels for superior plastic extrusion. Our expertly engineered screw barrels ensure efficient and precise extrusion for your production needs. Shop now and experience the difference in quality and performance! The conical twin screw barrel is a core part of a plastic extrusion machine that uses two conical screws to mix and knead materials. It has a good mixing effect, low energy consumption, high efficiency, etc.

Quality conical twin screw barrel

We are always developing new products for our conical twin screw barrels. The conical twin screw barrels are made from quality 38CrMoAlA, SKD11 and SKD61 tool steel. We are less likely to purchase raw materials from distributors. In contrast, we order directly from steel mills according to the parameters and elements we specify, thus ensuring the consistency of raw materials for screw barrel processing. Furthermore, all steel batches are tested for quality with German equipment.

For users of conical twin-screw barrels with different PVC formulations and filler ratios, we have developed different levels of wear and corrosion resistance. There are bimetallic alloy screw barrel, SKD sleeve-fit barrels, hard chrome plated twin screws, ceramic coating alloy screws, and so on. You can choose from a variety of screw and barrel combinations to meet your raw material formulation requirements. For the latest and best offers, please contact us.

HUACHEN conical twin screw barrel features

1. Heavy duty alloy steel with tempered and nitride.

2. Overlay of nickel-based and molybdenum-based alloys on vulnerable screw parts with a thickness of 1 to 1.5 mm. Effectively provide 1.5 times longer service life.

3. Optimised design for increased extruding output

4. Enhances extruder productivity by 25%

5. Conical twin screws with a much larger surface area in the feed zone

6. Improved feed efficiency and uniformity of heat transfer

7. A self-regulating closed temperature system in the screw core for high efficiency and energy efficiency

Applications

We classify our conical twin screw barrels according to the equipment used, and each application has a unique screw structure. The product equipment you require should be selected according to the appropriate conical twin screw model, conical screw design, and optimised wear process. We will provide you with a quote based on the most current information.

1. RPVC, UPVC, CPVC pipe extrusion

2. Double wall corrugated HDPE pipe extrusion

4. Planks, panels and sheets extrusion

5. PVC foam sheet and board extrusion

6. WPC sheet and board manufacturing

8. PVC compounding and pelletizing

Using advanced technology and screw barrel processing machines, we manufacture conical twin screw barrels that offer extra performance, heavy-duty, an exact fit, easy to use, and easy to remove. Twin screw barrels are specially designed for customers’ specific needs and requirements. A cost-effective solution is also offered.

Stork conical twin screw barrel models

| SJSZ35/75 | SJSZ38/76 | SJSZ45/97 | SJSZ45/100 | SJSZ48/118 | SJSZ50/105 | SJSZ51/105 | SJSZ53/128 |

| SJSZ55/110 | SJSZ55/120 | SJSZ58/125 | SJSZ60/125 | SJSZ63/130 | SJSZ65/120 | SJSZ65/132 | SJSZ65/138 |

| SJSZ72/150 | SJSZ80/143 | SJSZ80/156 | SJSZ80/173 | SJSZ92/188 | SJSZ110/200 |

| Extrusion brand | Screw barrel model |

|---|---|

| JINHU / JINHAILUO | SJSZ screw barrel |

| JWELL | SJSZ screw barrel |

| CINCINNATI | CM screw barrel, CMT screw barrel, KONOS screw barrel |

| KRAUSS MAFFEI | KMD screw barrel |

| WERBER | CE screw barrel |

| DAVID STANDARD | GC screw barrel |

>>The standard models of conical twin screws and barrels for the above models are in stock. To confirm the best price and delivery time, please contact us.

Materials

1) Based materials: Premium 38CrMoAlA, temperate and nitriding; 2) Barrel sleeve materials: SKD11, SKD61, Tungsten carbide alloy steel; 3) Plasma nitriding surface hardness: HV1000-1100; 4) Plasma nitriding depth: ≥ 0.7mm; 5) barrel sleeve surface hardness: ≥ HRC 62; 6) barrel sleeve thickness: 6-10 mm; 7) Alloy depth: 4-6 mm; 8) Alloy surface hardness: ≥ HRC 61.

>>Learn more about our conical twin screw barrel parameters

Our featured products and services

→ Bimetallic alloy screw barrel, hard chrome plating screw, ceramic coating alloy screw

→ Screw barrel engineering works,

→ Conical twin screw barrel installation skills

There is a wide selection of twin screw barrel models in stock. Generally, we can deliver within three to ten days from our factory in China. Meanwhile, our experience in import and export in China will make it easier for you to complete your international sourcing projects. For the latest stock and quotation information, please contact us.

About us

The company HUACHEN Screw is a reputed twin screw barrel manufacturer and supplier in Zhoushan, China. We also provide replacement conical twin screw barrels for many twin screw extruder brands worldwide. HUACHEN Screw Barrel began producing screws in 1993. Mainly, HUACHEN Screw are known for their wear resistance, consistency, and high output.