Maximizing Extruder Performance: How to Prevent Screw and Barrel Wear

Date:2023-2-07 Author:hcscrew

As a manufacturer of plastic products, you know the importance of having efficient and reliable extruder equipment. One of the biggest challenges faced by plastic product manufacturers is screw and barrel wear, which can significantly reduce the output and quality of their products. In this blog, we’ll discuss how to prevent screw and barrel wear and maximize the performance of your extruder.

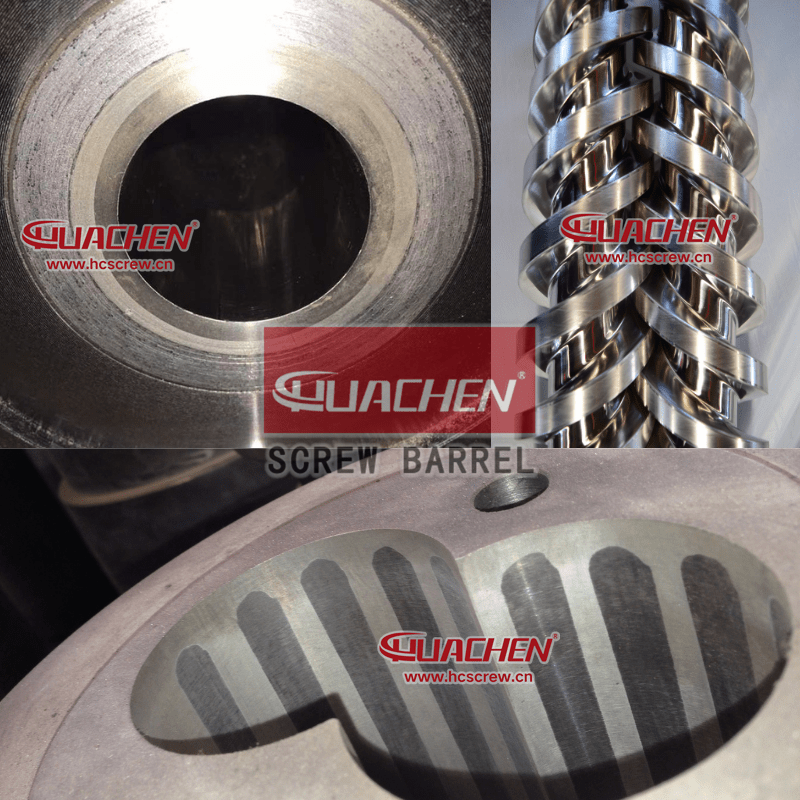

Screws and barrels work together in a plastic extruder. The combined work of the two parts has an impact on the plasticization of plastic materials, the quality of products, and the efficiency of production. As a result, the quality of the work depends on the manufacturing precision and the gap between the screw and barrel. During periods of severe wear and tear, you should replace the screw or barrel or arrange for their repair.

01 Understanding the cause of extruder screw and barrel wear, breaking, or getting damaged:

1. the extruder screw is rotated in the barrel.

Eventually, the extruder screw and the barrel’s working surface wear due to a combination of plastic material and friction. Gradually, the extruder screw diameter reduced and the barrel bore diameter increased. As a result, the screw and barrel of the extruder gradually wear away the gap diameter, with gradual wear of one and a small increase in the other. While the barrel in front of the head and the resistance of the manifold remain unchanged, the extruded material is more likely to leak forward. It increases the flow of material from the diameter gap to the direction of feed. This reduces the extruder’s production volume. As a result, the material in the barrel spends more time there, causing material decomposition. If the material is PE, polyethylene, hydrogen chloride is produced from its decomposition to reinforce corrosion of the extruder screw and barrel.

2. Wear and tear from the material being processed.

Materials such as calcium carbonate (CaCO3), wood powder, stone powder, and other fillers can accelerate the wear of the extruder screw and barrel.

3. The plasticisation of the material is not ideal.

Incorrect plasticisation or the presence of metal foreign bodies. As a result, the extruder screw rotation becomes more intense suddenly. The extruder screw becomes twisted off when the torque exceeds its strength limit. This is screw barrel unconventional accident damage.

Proper screw and barrel maintenance: Regular maintenance, such as cleaning and lubrication, can significantly reduce the risk of screw and barrel wear. Regular inspections can also help detect and repair any potential issues before they become more serious.

02 Proper processing conditions:

Proper processing conditions, such as controlling the temperature and pressure, can also help prevent screw and barrel wear. It’s also important to monitor and adjust the processing conditions to ensure that they are within the recommended range for the specific material being extruded.

Consider upgrading to a high-performance screw design: If you are experiencing frequent screw and barrel wear, consider upgrading to a high-performance screw design. These screws are designed to optimize the extrusion process and reduce the risk of wear.

Conclusion:

Preventing extruder screw and barrel wear is crucial for maximizing the performance of your extruder and ensuring the quality of your products. By understanding the cause of wear, using high-grade materials, maintaining your equipment, controlling processing conditions, and considering a high-performance screw design, you can significantly reduce the risk of extruder screw and barrel wear.

YOU MAY ALSO LIKE

| Bimetallic Alloy Screw Barrel ↗ Get details and latest price of bimetallic alloy screw barrel, heavy duty screw barrel, anti wear screw barrels and more at HUACHEN. |

| SKD Screw Barrel ↗ Get details and latest price of SKD sleeve fitting screw barrel, high-filled PVC twin screw extrusion parts, anti-wear screw barrel at HUACHEN… |

People also ask

HUACHEN Screw is sold directly from our factory in China for export. Please let us know the type of extruder screw barrel you are using, the type of product you are producing and the amount of filling such as calcium powder. Our engineering staff will recommend the optimum anti-wear solution for your screw barrel. Get the latest stock and pricing info from us.

Reception → screw barrel design checking and engineering service → prepare deposit → order manufacturing → quality control → finished product inspection → finished screw barrel checking → prepare balance payment → delivery → transportation

1. Business type: manufacturer, foreign trade company.

2. Origin: Zhoushan City, Zhejiang, China

3. Warranty: 12 months for fresh material.

4. International commercial terms: FOB, CFR, CIF, EXW

5. Scrcew barrel hs code: 8477900000

6. Terms of payment: T/T, L/C

7. Transport Package: AA Grade wooden case

You’ll get a reply from HUACHEN Screw within 1 hour or 24 hours.

More posts about extruder screw barrel wear:

HUACHEN Screw Barrel Recent Post

- High-performance PVC Screw Barrel for Efficient Extrusion

- Durable Conical Twin Screw Barrel for Precision PVC Pipe Production

- High-Speed Screw Barrel for Increased Extrusion Efficiency

- Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders

- High-Precision Parallel Twin Screw Barrel for Extrusion Excellence

- Top Quality Single Screw Barrels for Plastic Extrusion Applications

- High-quality Extruder Screw Barrel for Reliable Performance

- Efficient Plastic Extrusion Screw Barrel for Superior Output

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;