The Features And Process Of Blown Inflation Films

Date:2022-11-06 Author:hcscrew

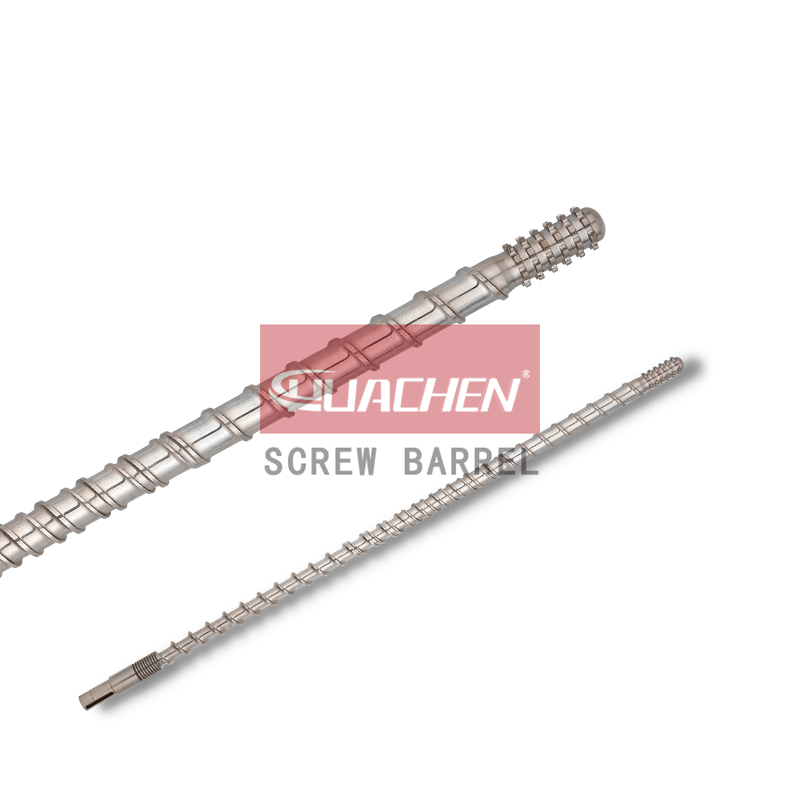

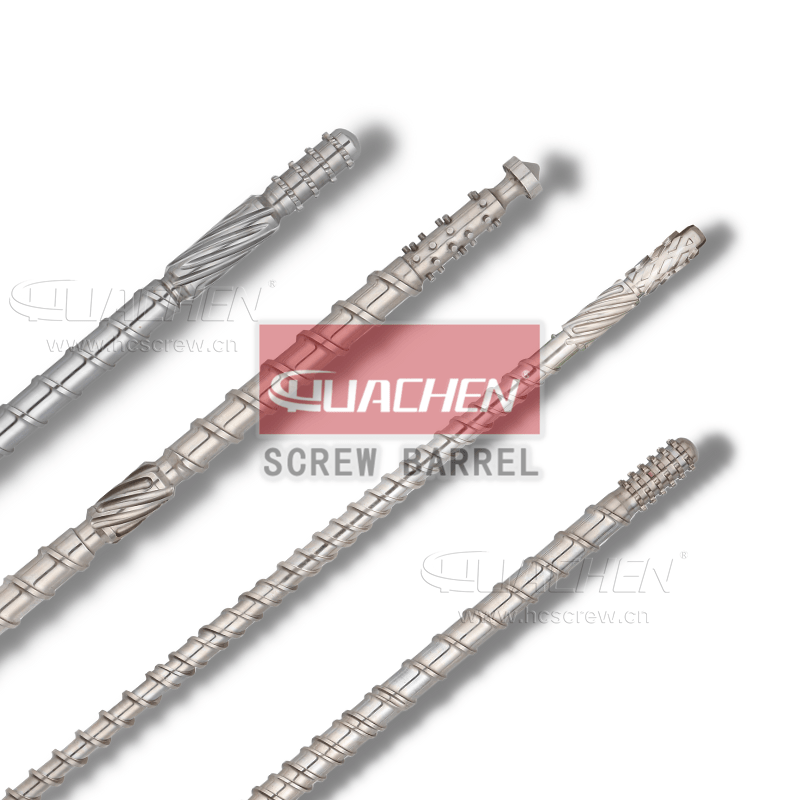

The performance of thermoplastic films depends both on the raw plastic particles used and on the production process and process parameters. Plastic products, like film, can be produced in different ways, i.e. using the same material and the same production process. Temperature, pressure, blowing ratio, and other process parameters affect the film’s performance. HUACHEN Screw, a manufacturer of high performance blown film screw barrels, introduces blown film today. It also discusses the characteristics and production process of blown films.

01 What is blown film?

A blow film, also called inflation film, is a polypropylene film that’s produced by blowing, also known as IPP film.

02 Blown film production features

(1) Blown film has a higher mechanical strength than cast film. It’s a two-way stretch of the plastic film, which explains the high mechanical properties of the traction rollers.

(2) Blown films can be used for heat sealing. Cast films have better heat sealing properties than blown ones, but most heat sealing films are blown.

(3) With the blown method, production is slower than with the cast method. Compared to cast film, there’s less uniformity in film thickness.

03 Process comparison for blown inflation films

1. Blown inflation film production points

(1) Stabilizer roller.

A stainless steel roller holds an inverted cone wrapped in felt. It blows air into the molten film bubbles on the mandrel of the mouth mold. It is possible to install a stability roller to provide a stable environment that prevents the film bubbles from wobbling and affecting the surface quality of the film. Pulling the molten bubble out of the felt creates an invisible stretching effect, which improves the mechanical strength of the film. For blown film uniformity, a stability roller works.

(2) The dew point.

When plastic turns from liquid to solid after melting, low and high dew points have a significant impact on how the film performs: blown film performs like cast film when it’s in a liquid state. In contrast, a low dew point line produces a blown film that is more like an oriented film and has poor heat sealing properties.

Adjust the amount of air in the air ring to change the height of the dew point.

(3) Blow-up and traction ratios.

Usually, the blowing ratio should be between 2 and 3. The blowing ratio is the ratio between the diameter of the film and the diameter of the mandrel or ring die. The higher the blowing ratio, the better the transparency and gloss. Films with a higher blowing ratio are stronger. However, if the film is too thin, the bubbles grow too big, causing unevenness, so it wrinkles easily. A film’s blowing ratio affects its lateral performance.

There’s a correlation between blister roller linear speed and film extrusion speed. Generally, the thinner the film, the better the long-term mechanical properties. A high traction ratio isn’t suitable, and a low blowing ratio isn’t either. It’s good to have a traction ratio of 4-6. At the right tension and blowing ratio setting, blown films should be able to balance cross-sectional and vertical performance. In any case, cross-sectional and vertical performance aren’t balanced, and cross-sectional is way more impressive.

(4) Second blown process.

The process involves blowing and defoaming plastic film, heating it with a heating roller, blowing it again, cooling, and winding it. Secondary blowing improves the openness of the film, makes it stronger, and makes it thinner. It’s also possible to improve the uniformity of film thickness.

Summary

Here’s a brief overview of blown film’s features and production methods. We’re a professional manufacturer of screws for plastic film and blown inflation films. Please contact us for the latest designs and quotations for high strength blown film extrusion screws and barrels.

YOU MAY ALSO LIKE

| Flexible PVC Film Blown Extrusion Screw Barrel ↗ Get details & price for flexible PVC film blown extrusion screw barrel. Better anti-wear screw barrels for film blown extrusion at HUACHEN… |

| Plastic Film PP Film Extrusion Screw Barrel ↗ Get details & prices for plastic film PP film extrusion screw barrel. Better anti-wear screw barrels for plastic film making at HUACHEN… |

| Blown Film Extruder Screw Barrel ↗ Get details & quote for blown film extruder screw barrel. Bimetallic alloy anti-wear screw barrels for better plastic film making at HUACHEN… |

About us

HUACHEN Screw has been an outstanding producer of blown inflation film screw barrel in Zhoushan Jintang since 1993. With many years of experience designing and processing plastic machinery replacement parts, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customization. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn more about our company

RELATED CONTENT ABOUT SCREW BARREL

- High-performance PVC Screw Barrel for Efficient Extrusion

- Durable Conical Twin Screw Barrel for Precision PVC Pipe Production

- High-Speed Screw Barrel for Increased Extrusion Efficiency

- Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders

- High-Precision Parallel Twin Screw Barrel for Extrusion Excellence

- Top Quality Single Screw Barrels for Plastic Extrusion Applications

- High-quality Extruder Screw Barrel for Reliable Performance

- Efficient Plastic Extrusion Screw Barrel for Superior Output

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;