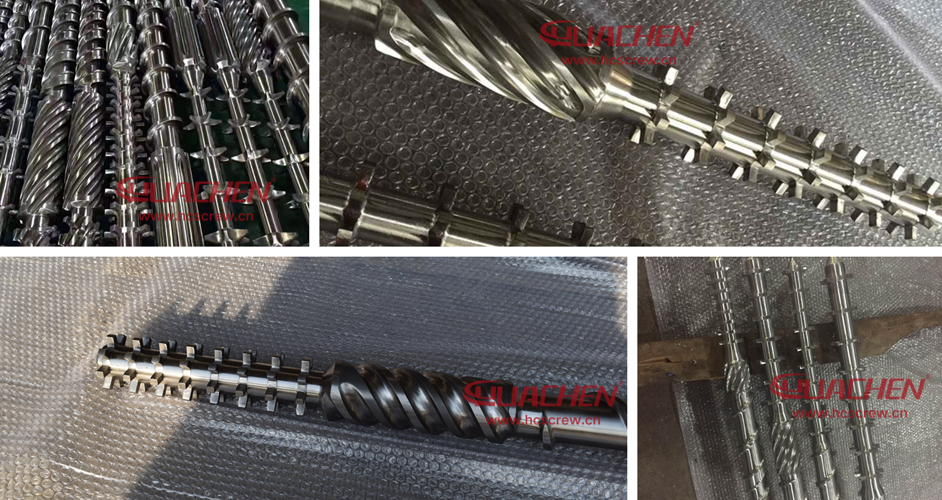

Grooved Barrel Extruder Screw

● Pipes extrusion

● Sheets extrusion

● Recycling pelletizing extrusion

● Blow film / Blow moulding

● PE / HDPE / PP

You Need Better Grooved Barrel Extruder Screw at Good Price!

- Product Detail

HUACHEN Screw has been a leading Grooved Barrel Extruder Screw manufacturer in Zhoushan Jintang since 2005. With many years of experience in the design and processing of plastic machinery accessories, HUACHEN Screw can provide its customers with a wide range of services including made-to-order screw barrels, rebuilding, modification, and upgrade. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn more about our company

Grooved Barrel Extruder Screw

Grooved barrel extruders are popular in the market because of their high output, low temperature extrusion, and low energy consumption. Users in China call it a high efficiency high speed extruder. Grooved barrel extruders have a grooved feeding barrel, which is the most distinctive feature compared to single screw barrels. A grooved feed extruder screw is used in combination with this.

It’s a new barrier screw with a forced feed screw structure. Based on experience, it combines the barrier screw, straight Maddock or spiral Maddock, and Pineapple to meet the high speed requirements of the grooved barrel extruder. This combination of forced feed screw can generate high pressures in the feed section and continue to influence the structure in the following sections. Die pressure does not affect output much anymore. Additionally, the screw’s feed section develops a lot of pressure, which reduces fluctuations during extrusion. The screw increases output linearly with screw speed. The grooved barrel extruder screw is combined with a grooved feeding barrel to get higher output.

Advantages and application of grooved barrel extruder screw

It features a high plasticisation speed, a large feed volume, and a stable current.

We offer our customers a better balanced screw structure. The screw has a reasonable structure, is easy to assemble, has a long service life, is highly productive, and consumes little energy.

In addition to solid wall HDPE pipe extrusion, it can also extrude PPR pipe, MPP pipe, coil pipe, corrugated wall HDPE pipe, and insulation pipe. Furthermore, it is a standard configuration for the production of high-quality plastic blow film extruder and blow moulding machine.

Grooved barrel extruder screw specifications

1) Single screw diameter available: 45mm to 150 mm; 2) Single screw L/D ratio available: 30 to 40; 3) Barrel max. length: ≤10000 mm; 4) Barrel max. out diameter: ≤350 mm; 5) Based materials: Premium 38CrMoAlA (UNS K24065, SACM645, 41CrAlMo7-10),SKD11; 6) Plasma nitriding surface hardness: HV 1000-1100; 7) Plasma nitriding depth: ≥ 0.7 mm; 8) Nitriding fragility: less than Grade I; 9) Surface Roughness: Ra 0.4 μm; 10) Screw Linearity: ≤ 0.015mm; 11) Alloy depth: 2-4 mm; 12) Alloy surface hardness: ≥ HRC 61.

>>Learn more about our groove barrel extruder screw parameters

Our grooved barrel extruder screw ultimate solution for abrasion and wear

1. Alloy steel of high strength, tempered, and nitride.

2. Overlay of nickel-based and molybdenum-based alloys on vulnerable screw parts with a thickness of 1 to 1.5 mm. Effectively provide 1.5 times longer service life.

3. hard chrome plating as optional process.

>>Learn more about our bimetallic screw treatments

Production time

Complete screw barrel set within 30-38 days depending on the complexity of the part.

We have a wide selection at good prices to help you get creative. The grooved barrel extruder screw for Sale is guaranteed to be of high quality. We are the China Origin Factory of grooved barrel extruder screws. If you have any questions, please feel free to contact us.