Hard Chrome Plating Screw Barrel

● Min. Order (MOQ): Set

● PVC foam sheet, board extrusion

● PVC window or door profile extrusion

● PVC wall panels, ceiling extrusion

● WPC planks, door sheets, board extrusion

● SPC rigid vinyl plank sheet board extrusion

● Blown film / Lamination

● GF injection Moulding

You Need Better Chrome Plating Screw Barrel at Good Price!

- Product Detail

Looking for a solution to increase the durability of your plastic extrusion machine? Our hard chrome plated screw barrels are the answer! Our custom-made barrels are designed to provide optimal performance and extend the lifespan of your machine. Contact us to learn more.

Hard chrome plating screw barrel, enhance durability of your extrusion machine

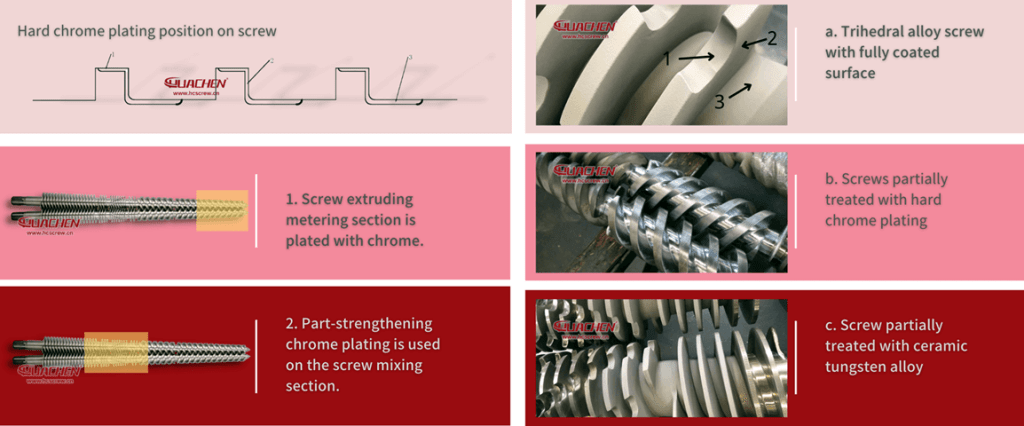

- The screw barrel chrome plating process is an effective way to prevent wear and corrosion, which is widely used in injection moulding machines when processing glass-filled fibres and in extrusion machines when processing resins containing high fillers. We use chrome plating for both conical twin screws and parallel twin screws to process PVC and PE products with very high fill levels. Hard chrome plated screws are made from 38CrMoAlA nitrided steel. Hard chrome plating is applied to the screw’s most damaged and worn areas. It completely covers the screw base, screw flights, and screw surface.

- Chrome plating on our screws is 0.05-0.10 mm thick and does not simply adhere to the surface of the screw, but is firmly bonded to the screw base. We must ensure that the chrome plating does not chip off and be scrapped because of the processing strength of highly filled PVC and PE products.

- We use screw chrome plating in conjunction with our bimetallic alloy screw process to give your highly filled special screws better corrosion and wear resistance.

Advantages of HUACHEN hard chrome plating screw barrel

- 1. Improving the corrosion resistance of the screw

- 2. improve screw wear resistance

- 3. Processed materials scorch less due to reduced polymer viscosity

- 4. Faster screw cleaning.

Application of Hard chrome plating screw barrel

- 1. PVC conical twin screw for foam sheet, board extrusion

- 2. PVC conical twin screw for window or door profile extrusion

- 3. PVC conical twin screw for siding and wall panels, ceiling extrusion

- 4. WPC conical twin screw for planks, door sheets, board extrusion

- 5. SPC conical twin screw for rigid vinyl plank sheet board extrusion

- 6. Parallel twin screw barrel

- 7. Blown film screw barrel

- 8. Injection moulding screw barrel

Premium Materials

- –Core Materials: Premium 38CrMoAlA, SKD11, SKD61

- –Plasma Nitriding Surface Hardness: HV 1000-1100

- –Plasma Nitriding Depth: ≥ 0.7mm

- –Nitriding Fragility: Less than Grade I

- –Surface Roughness: Ra 0.4 μm

- –Screw Linearity: ≤ 0.015mm

- –Alloy Depth: 4-6mm, 6-10mm

- –Alloy Surface Hardness: ≥ HRC 61

- –Hard chrome plating layer thickness (optional): 0.05-0.10 mm

- –Hard chrome plating layer hardness (optional): ≥ HV 950

For detailed parameters, visit our hard chrome plating screw barrel parameters.

Fast Production Times

- –Ready Stock Models: Available within 7 days.

- –Custom-Made Models: Available within 45 days, depending on part complexity.

How to Order from HUACHEN Screw

Ready to upgrade your production with HUACHEN’s conical twin screw barrels? Follow our simple Step-by-Step Guide to Order from HUACHEN Screw:

- 1. Contact Us: Reach out to our sales team via email or phone.

- 2. Specify Requirements: Provide detailed specifications and requirements for your project.

- 3. Receive a Quote: Our team will provide a customized quote based on your needs.

- 4. Place an Order: Confirm the order and provide necessary payment details.

- 5. Production and Delivery: We will manufacture your order and arrange for timely delivery.

For inquiries or more information, please contact us.

About HUACHEN Screw

Since 1993, HUACHEN Screw has been a leading hard chrome plating screw barrel manufacturer in Zhoushan Jintang. As a pioneer in designing and processing wear-resistant PVC screw barrels, we offer a wide range of services, including drawing rebuilding, design, modification, and custom screw barrels. Our products are trusted globally for their high performance and efficiency.

To learn more about our company and services, please visit our About Us page.