How to Pick the Best Conical Twin Screw Barrel Design?

Date:2022-11-27 Author:hcscrew

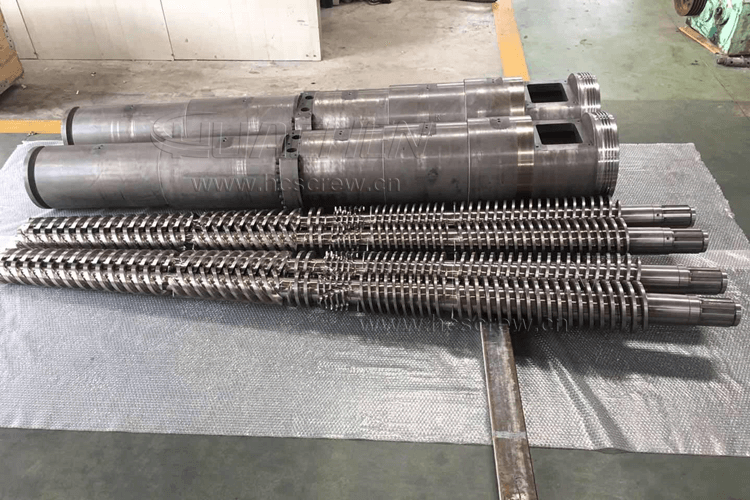

A common question we receive from customers is why the screw they use to extrude their goods does not work well. In fact, the conical screw will be offered in a wide variety of designs, which can be used for different formulations and products. It looks like they’re all pretty similar at first. For twin screw barrel manufacturers, the conical twin screw design includes many elements, variations, and functions. Here, HUACHEN Screw explains the differences between conical twin screw barrels. Also, how to pick the right conical twin screw barrel design.

01 Designs of conventional screw, low filler screw, and high filler screw and features

1) Conical twin screw flights, screw groove shape, and how to pick them. If you produce PVC with low filler calcium carbonate powder (CaCO3 ), there should be a lot of space between the conical screw flights. Or if you are producing PVC with high calcium carbonate powder (CaCO3 ) filler, there should be a small space between the screw flights. In order to increase plasticity and shear force.

2) According to the function of the screw, conical twin screws have six sections, generally divided into the feeding section, compression section, barrier section, mixing section, venting section, and metering section.

Feeding section: A conical twin screw with a big space between the screw flights feeds fast, and vice versa. It’s also related to PVC product formulas and calcium carbonate powder (CaCO3 ) filled ratios.

Compression section, barrier section, mixing section: PVC raw material’s plasticizing ability is largely affected by the combination of these three sections, and especially the barrier section. Adding a barrier section before the compression section can increase plasticisation. This is good for making high-calcium PVC formulas. When there’s no barrier section and only the mixing and compression sections are kept together, it’s only suitable for low-calcium PVC formulas.

Venting section: Through the venting port, you can see how well the material plasticizes. As the melt solidifies, granules, powders, and ribbons appear.

Metering section: Extrusion is fast when there’s a big gap between the screw flights.

02 Design of low filler screws, high filler screws, and features

In the low filler screw, there’s a feed section, a compression section, and a mixing section. In a conical twin screw, we make the last part of the feeding section smaller and turn it into a compression section. After that, make a groove in the compression section and add two layers of barrier to increase plasticization. There should be a bigger gap between the two screw flights in the venting section and the metering section.

High filler screw design has seven sections: feeding section, barrier section, compression section, second barrier section, mixing section, venting section, and metering section. There’s a smaller gap between the feeding and metering sections.

03 Conical twin screw barrel temperature control system

1) Temperature control in the conical twin screws

Distilled water circulates automatically in the internal circulation. Using screw temperature control, you can control the temperature of the raw material. During extrusion start up and in the production process, the screw’s temperature control system protects the screw and provides stable production when the extruder is on. It is easy for PVC products to discolor if the screw does not use a temperature control system, especially when producing PVC profiles.

2) Temperature control on the conical barrel

Temperature control systems for conical barrels are available with air cooling or oil cooling. Temperature control with oil-cooling is more accurate than with air cooling. However, oil cooling oil pipes can get clogged more easily and have a higher failure rate than air cooling ones.

04 Conical twin screw design on PVC pipes and PVC profiles

1) Pick conical twin screw design

More than 120% calcium carbonate (CaCO3) filler: The screw’s metering section should have a small clearance. There’s not enough compression if there’s a big gap in the metering section. The mixing section needs more grooves, which determine the plasticization effect. The PVC product formulation needs a high calcium screw.

30–80% calcium carbonate (CaCO3) filler: Processing with A high calcium screw, but with reduced screw flight gap between the feeding section and metering sections.

0–30% calcium carbonate (CaCO3) filler: Compression, mixing, and feed sections are all connected, but metering has a bigger gap between screw flights.

2) Pick low filled screw or high filled screw

PVC products made with different formulas require different screws. Choosing a conical twin screw design depends on how much CaCO3 is in the plastic product formulation and how much lubricant it contains. Lubricants make plasticising less effective, but they improve flowability.

3) High filled conical twin screws need a higher standard

High filler PVC making formulas wear out the screw and barrel a lot faster. Their service life is usually short. Generally, PVC pipes and profiles above 100 parts CaCO3 powder begin to wear after 5-6 months. Processing below 80 parts CaCO3 powder starts to wear out in a year, causing blue lines and black lines. Most barrel wear happens in the barrel venting port and metering section, as well as screw feeding section wears out. The barrel metering section and other parts prone to wearing can be made hard with bimetallic alloys so that the wear is better than nitrided barrels. However, the conical barrel won’t be used for more than two years. We’ve also developed an upgraded SKD sleeve fitted barrel for better barrel wear resistance.

Summary

The above is a brief description of the many conical twin screw barrel structures. If you would like to know more skills about conical twin screw barrel and request a quotation, please contact us HUACHEN Screw Barrel Factory.

About the twin screw barrel Factory: HUACHEN

HUACHEN Screw has been a leading conical twin screw barrel manufacturer in Zhoushan Jintang since 1993. As one of the leading companies in designing and processing parallel and conical twin screw extrusion screw barrel, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customized screw barrels. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn more about our company

You May Also Like

| PVC Pipe Conical Twin Screw Barrel ↗ Get PVC pipe conical twin screw barrel details and prices from HUACHEN screw barrel factory. Good plasticisation, heavy duty screw barrel. |

| PVC Profile Conical Twin Screw Barrel ↗ Get details and price of PVC profile conical twin screw barrel. Better PVC profile twin screw barrel for PVC window door profiles at HUACHEN. |

| Conical Twin Screw Barrel ↗ Get latest & most competitive prices on China conical twin screw barrel, extruder barrels, extruder screw, bimetallic screw, SKD barrels… |

| Twin Screw Barrel ↗ Get latest good prices on China twin screw barrel, parallel conical twin screw barrel. Advantages, comparisons, materials, models… |

TAGS

HUACHEN Screw barrel recent post

- High-performance PVC Screw Barrel for Efficient Extrusion

- Durable Conical Twin Screw Barrel for Precision PVC Pipe Production

- High-Speed Screw Barrel for Increased Extrusion Efficiency

- Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders

- High-Precision Parallel Twin Screw Barrel for Extrusion Excellence

- Top Quality Single Screw Barrels for Plastic Extrusion Applications

- High-quality Extruder Screw Barrel for Reliable Performance

- Efficient Plastic Extrusion Screw Barrel for Superior Output

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;