The 8 Types Of Plastic Construction Pipes

Date:2022-7-21 Author:hcscrew

Our plastic extrusion industry is no stranger to plastic construction pipes. As a manufacturer of extrusion screws, HUACHEN Screw Barrel has always focused on developing more efficient extrusion screws. The effective use of extruders requires a thorough understanding of plastic construction pipes. What are the different types of plastic construction pipes?

Construction pipe #1: UPVC rigid water pipe (non-lead salt stabiliser)

UPVC stands for rigid polyvinyl chloride and PVC stands for polyvinyl chloride. As a result of the lead salts added to most UPVC production, it is harmful to humans. Only a small percentage of pipes without lead salts are suitable for use as water supply pipes.

It should be a UPVC blend. An additive mix is used to produce a pipe of the required quality based on PVC resin. UPVC water pipes for drinking water do not contain lead salt stabilisers.

Rigid UPVC rigid water pipe appearance: The inside and outside of UPVC rigid water pipes should be smooth and free of obvious scratches and dents. Pipe ends are cut flat and perpendicular to the axis.

Features of UPVC rigid water pipe

1) High hardness, stiffness, and stress tolerance.

2) High resistance to age and durability, with a life expectancy of up to 50 years.

3) Easy to bond, corrosion resistant, inexpensive, and self-extinguishing.

4) Recyclable, easy to install, and provides effective sealing.

5) A lack of impact resistance, poor durability, high technical requirements for joint bonding, and a long curing time.

Construction pipe #2: UPVC drainage pipe

PVC resin is the main raw material in UPVC drainage pipes, along with stabilizers, lubricants, fillers, colour enhancers, and other additives. Following the extrusion and injection of pipes and fittings, plastic extruders cool, cure, shape, check, and package the products as well. Water supply and drainage are ideal applications for this material.

Features of UPVC drainage pipe

1) UPVC drainage pipes have excellent physical and chemical properties. Its chemical corrosion resistance, high impact strength, low fluid resistance, 30% greater flow rate than cast iron pipes of the same size, aging resistance, long service life, with a lifespan of at least 50 years, makes them the most suitable material for water supply and drainage systems in buildings.

(2) Easy to install, lightweight, and powerfully accelerated project progress.

(3) Save construction costs, compared to cast iron pipe of the same specification.

Construction pipe #3: Underground Double Corrugated UPVC Pipe

PVC resin is the main raw material for rigid polyvinyl chloride pipes. It is extruded into pipe shapes and mixed with additives. PVC is the most commonly used material for underground drainage and waste water pipes. There are two types of connection pipes: flexible seal connection pipes (φ110mm to φ630mm) and adhesive connection pipes (φ110mm to φ200mm). It is possible to use underground sewage and wastewater pipes for industrial drainage because of their chemical and heat resistance.

Features of Underground Double Wall Corrugated UPVC Pipe

1) Excellent flame retardant properties as well as impact resistance.

2) A smooth interior wall of the product.

3) A corrugated outer wall and hollow structure contribute to the product’s light weight and high stiffness.

(4) Socket-type connection, rubber ring seal, easy installation, and maintenance.

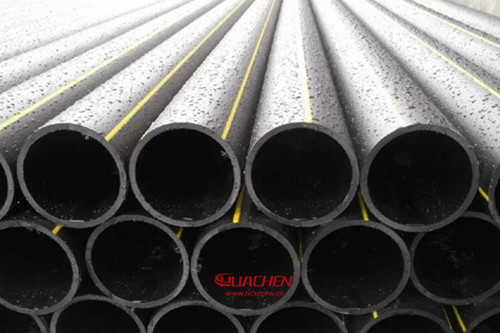

Construction pipe #4: PE underground gas pipes

PE underground gas pipes are extruded products. The product is safe for use, has a low leakage rate, and has excellent corrosion resistance. Also, it is lightweight, strong, easy to construct, versatile, and environmentally friendly. In general, underground pipelines transport natural gas and synthetic gas.

Features of underground PE gas pipe

1) Easy to install and operate

There are two ways to connect PE underground gas pipes. The electric fusion connection is generally applicable to pipes with a diameter of less than DE110. Hot fusion is the second type of connection. Pipes with a diameter of not less than DE110 are generally used without sleeves in the butt. Within a short period of time, all of the above connection methods can be learned, and the quality of welding and construction progress can be ensured. Additionally, a gas open tie can be installed in a gas pipe network that is already in operation. Using steel pipes as gas pipelines prevents this process.

2) Strong corrosion resistance, long life underground due to anti-corrosion treatment

PE pipe does not require corrosion treatment. Additionally, steel pipes usually last for 20 years.

3) Strong adaptability to construction

A limited amount of space is available for the layout of pipes in residential communities and municipal projects. Flexible PE pipe bends easily under curved surfaces. Meandering installation is possible in a circumvent, allowing for meandering installation.

4) Low investment cost

1.PE gas pipe is more expensive than gas steel pipe. It has a large diameter, hot melt connections, and will last for a long time without corroding. In comparison to this comprehensive price, steel pipe is cheap.

2. There are two underground PE gas pipes that are flexible and completely prefabricated on the ground. Because it is laid in a trench, no pit is needed. Therefore, trench construction of PE pipe requires a much smaller pit than trench construction of steel pipe, and therefore requires less earth.

3. PE gas pipe underground testing procedures, methods, and means are simple and effective, and the testing fee is low.

Construction pipe #5: HDPE water supply pipe

The advantages of HDPE (high-density polyethylene) in the manufacturing of water supply pipes include its high strength, corrosion resistance, and inertness. It is ideal for replacing ordinary iron water pipes because it does not rust. In addition to building water supply, building drainage, buried drainage pipes, heating and gas pipes, electrical and telecommunication protection casings, industrial pipes, and agricultural pipes, HDPE pipes offer a number of unique advantages. Urban water supply, urban gas supply, and agricultural irrigation are the main applications.

Features of HDPE water supply pipe

1) Corrosion resistance

It is corrosion resistant, sanitary, and long-lasting. Except for a few strong oxidants, polyethylene is non-inert, chemically resistant, and not easily contaminated. Polyethylene pipe has a 50-year service life.

2) Flexibility

Polyethylene is flexible and scratch-resistant. The polyethylene pipe system is flexible from a technical and economic perspective. Polyethylene’s flexibility is invaluable in pipeline projects. So, using flexible polyethylene pipes, you can get longer lengths and fewer joints.

3) Resistance to low temperatures

Low temperatures are no problem for polyethylene. PE pipe has a low temperature embrittlement point of -70°C, which is higher than other pipes.

(4) Toughness to fracture

Polyethylene has an excellent crack growth and fracture toughness.

Construction pipe #6: Underground double-wall corrugated PE pipe

Double-wall corrugated PE pipe is a lightweight pipe made of polyethylene designed for underground drainage. The process involves extrusion and special moulding. With a smooth inner wall and a corrugated outer wall, this double-wall corrugated pipe has excellent performance and excellent quality. There are many applications for the product, such as municipal sewage drainage, agricultural and garden drainage and irrigation, underground drainage outside buildings, ventilation and drainage in mines and tunnels, protection covers for communication cables and optical cables, as well as various road and court drainages.

1) The inner and outer layers of the pipe have uniform colours, with the outer layer usually being black.

2) No blistering, denting, obvious impurities, or irregular corrugations on the outside wall are allowed.

3) Pipe ends should be flat, perpendicular to the axis, and located in the trough area.

Features of PE underground double-wall corrugated pipe

1) Resistance to aging and corrosion, long service life.

2) Low resistance to flow, smooth inner wall, and no scaling.

3) Effective sealing, not prone to leaks.

4) Vibration and impact resistance.

5) Excellent hygiene performance and environmental protection.

6) Lightweight, easy to construct, easy to maintain, and low overall cost.

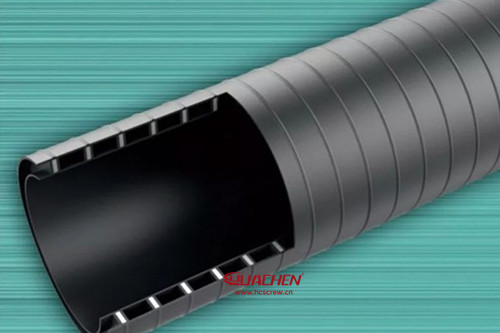

Construction pipe #7: HDPE hollow spiral pipe

The most common type of drainage pipe is a hollow spiral pipe. The manufacturing process involves forming rectangular polyethylene pipe blanks with excellent quality fusion joints from high-density polyethylene (HDPE). With HDPE pipes and fittings, you can create a leak-proof, zero-leak pipeline system. Their use is extensive in underground rainwater and sewage networks, underground corridors, and rain water collection systems in a variety of soil environments and depths.

Features of HDPE hollow spiral pipe

1) Excellent resistance to chemical corrosion and erosion.

2) Strong impact resistance and stable flexibility.

3) Cold resistance, aging resistance, easy connection, safe, and reliable.

4) Lightweight and easy to construct.

5) High wear resistance, long service life, and maintenance-free throughout the life of the product.

6) Excellent drainage, superior hygiene, and recyclable.

Construction pipe #8: electric PVC conduit pipe

The classification of PVC conduit pipe:

A. PVC cable wire pipes: suitable for load-bearing walls, 8mm pipe diameter can be reduced.

B. Corrugated PVC pipe: this material is suitable for wiring in narrow spaces such as ceilings, since it is ductile and bends freely.

C. Red and Blue PVC conduit pipe: It has red and blue shunts, strong and weak electricity, and better circuit installation and maintenance.

D. PVC trigeminal conduit: it is compartmentalised directly in the inner tube wall to specify cable routing and the tube diameter used in each compartment, facilitating line differentiation and preventing short circuits.

Features of electric PVC conduit pipe

1) Resistant to high pressure

Suitable for hidden laying in compacted or vibrating concrete, the heavy-duty tube series and medium-duty tube series can withstand strong pressure without breaking under pressure.

(2) Resistance to corrosion and pest control

The PVC conduit is highly resistant to acids and alkalis. In addition, PVC pipe does not contain plasticizers, so insects and rodents are not at risk.

3) Flame retardant properties

Since PVC conduit has poor heat transfer properties, in the event of a fire the line can be effectively protected for a longer period of time. This will facilitate evacuation of personnel and keep the fire from spreading along the conduit pipe.

(4) Effective insulation properties

By absorbing high voltage without being damaged, it effectively avoids metal and electric shock hazards.

5) Easy to construct

A. Lightweight: only one fifth the weight of steel pipe, easy to transport by vehicle and carry manually, light and labour-saving during construction and installation.

B. Bendable: As long as the bending spring provided by the company is inserted in the tube, it can be bent manually at room temperature.

C. Easily cut and joined: PVC conduit pipes up to 32 caliber can be easily cut with special cutters, and with special adhesives and accessories, they can be easily joined into any required shape.

D. Cost savings: compared to steel pipes, PVC conduit pipes can reduce construction and installation costs.

Summary

The above is a list of 8 types of plastic construction pipes processed by PVC screw barrels and PE screw barrels. Please contact us for more information and advice about plastic construction pipe extrusion. Or contact us for an up-to-date quote on a relevant screw barrel.

TAGS

HUACHEN Screw Barrel Recent Post

- High-performance PVC Screw Barrel for Efficient Extrusion

- Durable Conical Twin Screw Barrel for Precision PVC Pipe Production

- High-Speed Screw Barrel for Increased Extrusion Efficiency

- Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders

- High-Precision Parallel Twin Screw Barrel for Extrusion Excellence

- Top Quality Single Screw Barrels for Plastic Extrusion Applications

- High-quality Extruder Screw Barrel for Reliable Performance

- Efficient Plastic Extrusion Screw Barrel for Superior Output

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;