Meltblown Nonwoven Fabric Screw Barrel

● Min. Order (MOQ): 1 screw + 1 barrel / Set

● PP meltblown nonwoven fabrics

● Surgical gowns, protective clothing, sterilization wraps, masks, and diapers.

You Need Better Meltblwon Nonwoven Extruder Screw Barrel at Good Price!

- Product Detail

HUACHEN Screw has been a top producer of meltblown nonwoven fabric extruder screw barrel in Zhoushan Jintang since 1993. With many years of experience designing and processing plastic machinery accessories, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customization. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn more about our company

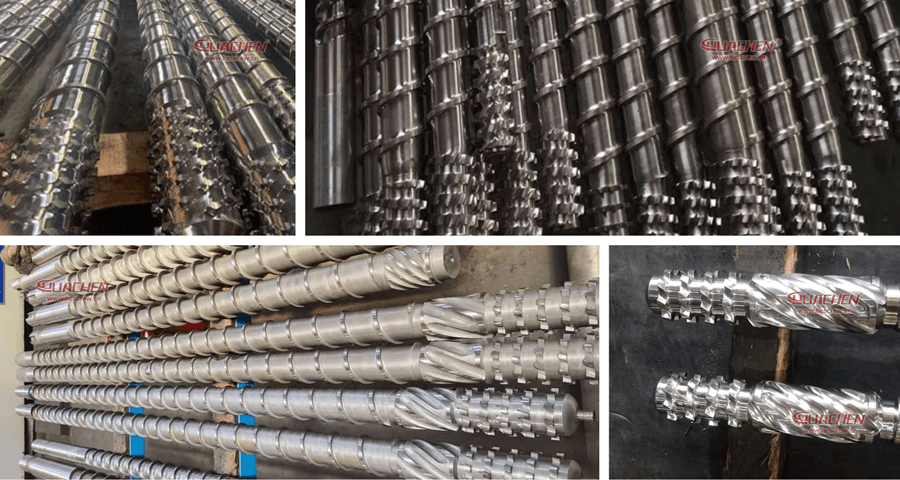

Meltblown nonwoven fabric screw barrel

What is PP meltblown nonwoven fabric?

PP meltblown fabrics are commonly used in medical and hygiene products, clean materials, thermal and acoustic insulation cotton, oil-absorbing materials, battery partitions, and air filtration. Among the most important protective materials, the mask, consists of an inner and outer spunbond layer (S layer) and a middle meltblown layer (M layer), which is the mask’s heart and mainly serves to block and adsorb particles and droplets. PP meltblown fabric is the main material of the M layer. It has a high melt index, low molecular weight, high stability, low odour, and forms a high strength fibrous web.

How do plastic extruders manufacture PP meltblown nonwoven?

PP meltblown nonwovens are produced in roughly two steps. First, powdered PP speciality resin is modified and mixed, then extruded through an extruder to produce granular or flake PP modified meltblown fabric specialities. Next, PP meltblown nonwoven single screw extruders melt the special material in slices or pellets and plasticize and extrude it into a homogeneous PP melt.

HUACHEN offers high-quality meltblown nonwoven screw barrel

HUACHEN Screw’s Meltblown nonwoven fabric single screw barrel is designed mainly for extruding PP meltblown nonwoven material into meltblown form. It is the key to producing high quality PP meltblown fabric. For the screw barrel, we use high-quality 38CrMoAlA, which is subjected to a rigorous nitriding and tempering process. The screw barrel can also be treated with an upgraded bimetallic alloy to increase its life.

Screw diameters and L/D ratios can be supplied in D50/30, D65/30, 75/30, 90/30, 105/30, 150/30 etc. The screw designs are available in conventional single screw as well as combination screw styles including barrier screw, maddock screw, and screw mixing head (pineapple). We can supply the barrels with a normal smooth bore barrel or with an upgraded grooved feed bore barrel to increase the feeding and plasticizing effects of PP meltblown fabrics.

Our screw barrels for PP meltblown provide good plasticisation and stability of the PP material, which helps the subsequent process to efficiently and evenly spray finer PP meltblown fibres to produce soft, evenly distributed PP meltblown fabrics.

Specifications for meltblown nonwoven fabric extrusion screw barrels

| Meltblown nonwoven fabric SB model | Screw L/D ratio | Screw rpm(r/min) | Drive motor power | Max. output(kg/h) |

|---|---|---|---|---|

| φ105 | 30 | 75 | 55 | 160 |

| φ120 | 30 | 75 | 75 | 200 |

| φ130 | 30 | 75 | 90 | 220 |

| φ140 | 30 | 75 | 90 | 300 |

Parameters

1. Single screw diameter available: 45 mm to 180 mm

2. Single screw L/D ratio available: 25 to 30

3. Screw max. length: ≤10000 mm

4. Barrel max. out diameter: ≤350 mm

5. Based materials: Premium 38CrMoAlA

6. Plasma nitriding surface hardness: HV 1000-1100

7. Plasma nitriding depth: ≥ 0.7 mm

9. Nitriding fragility: less than Grade I.

10. Surface Roughness: Ra 0.4 μm

11. Screw Linearity: ≤ 0.015mm

12. Alloy depth: 6-8 mm

13. Alloy surface hardness: ≥ HRC 61

>>Learn more about our wire cable extruder screw barrel parameters

Production time

Complete set of meltblown nonwoven fabric screw barrel within 20-30 days depending on the complexity of the part.

We have a wide selection at good prices to help you get creative. The meltblown nonwoven fabric screw barrel for sale is guaranteed to be of high quality. We are the China Origin Factory of meltblown nonwoven fabric screw barrel. If you have any questions, please feel free to contact us.