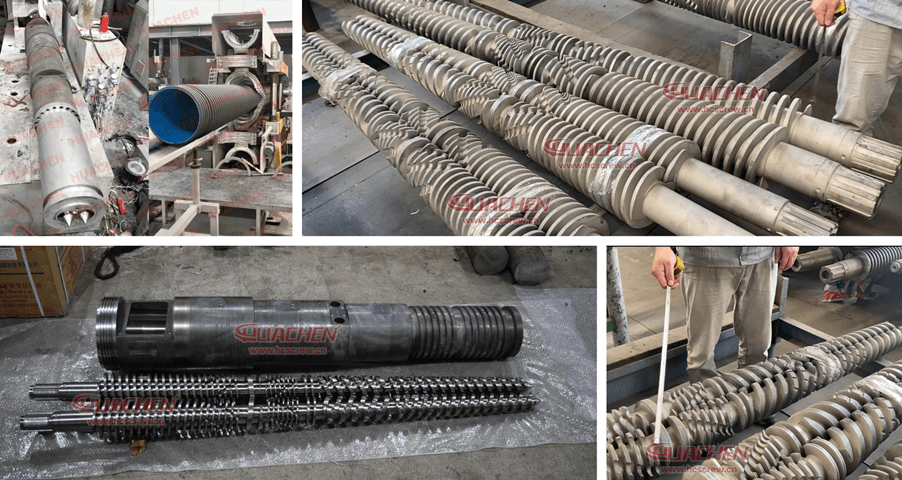

PE Pipe Extruder Conical Twin Screw Barrel

● PE / HDPE / WPC Matrix Polyethylene, virgin or recycled materials

● Large pipe, solid wall pipe, corrugated wall pipe, coil pipe

● Min. Order (MOQ): 2 conical screws + 1 barrel

● Based material: Premium 38CrMoAlA tempered and nitrided

● Anti-wear solution: SKD sleeve fitted barrel + bimetallic screw, bimetallic barrel + bimetallic screw

You Need Better Conical Twin Screw Barrel at Good Price!

- Product Detail

Boost Your PE Pipe Production with HUACHEN’s Conical Twin Screw Barrels

Upgrade to the Best in the Industry!

Discover how HUACHEN’s innovative conical twin screw barrels can transform your PE pipe extrusion process. Our cutting-edge technology delivers superior performance, increased efficiency, and significant energy savings.

Why Choose HUACHEN’s Conical Twin Screw Barrels?

- –Double Your Output: Achieve nearly double the output compared to single screw barrels with the same power motor.

- –Save on Energy Costs: Cut electricity usage by 40% annually, reducing your operational costs.

- –Enhanced Durability: Built from premium 38CrMoAlA steel and treated for maximum wear and corrosion resistance.

- –Versatile Applications: Perfect for large solid wall PE pipes, double-wall corrugated pipes, wood-plastic PE sheets, and more.

Key Features

- –High Efficiency, Low Energy Use: Direct powder mix extrusion with unique compression ratio and thread configuration.

- –Superior Design: Low-shear, high-conveyance screws increase output and pipe production speed, allowing for in-line flaring and other operations.

- –Venting Ports: Prevent air bubbles caused by moisture in raw materials for high-quality pipe production.

- –Quality Materials: Premium steel, plasma nitriding, and bimetallic alloy treatments ensure long-lasting performance.

Two Levels of Screw Barrel Options

- –Level 2: SKD sleeve fitted barrel and bimetallic screws for the highest quality and performance.

- –Level 1: Bimetallic barrel and bimetallic screws offering excellent durability and efficiency.

Applications

- –HDPE Pipe Extrusion: Large solid wall and corrugated wall (double and single).

- –Polyethylene Coil/Spiral Pipe Extrusion

- –Wood Composite PE Sheet and Board Extrusion

- –Corrugated Wall FRPP and PVC Pipe Extrusion

Model Specifications

| Model | Speed (RPM) | Motor (KW) | Capacity (kg/h) | Screw length (mm) | Barrel length (mm) | Weight (kg) | Package dimension (m) |

|---|---|---|---|---|---|---|---|

| HCZS 80/156 | 34.7 | 55 | 500 | 2116 | 1850 | 775 | 2.2*0.4*0.5 |

| HCZS 92/188 | 34.7 | 110 | 800 | 2805 | 2520 | 1500 | 3.0*0.5*0.6 |

Premium Materials

- 1. Core Materials: 38CrMoAlA, UNS K24065, SACM645, 41CrAlMo7-10, SKD11

- 2. Plasma Nitriding Layer: 0.7 mm

- 3. Nitriding Surface Hardness: ≥HV1000

- 4. Nitrided Screw Barrel Fragility: Less than Grade 1

- 5. Surface Roughness: Ra 0.4μm

- 6. Screw Linearity: ≤0.015 mm

- 7. Alloy Surface Hardness: HRC≥61

- 8. Alloy Depth: 1.5 mm

- 9. SKD Sleeve Surface Hardness: HRC≥62

- 10. SKD Sleeve Thickness: 6-10mm

For more detailed information, visit our PE Pipe Extruder Conical Twin Screw Barrel Parameters page.

Fast Production Times

- –Standard Models: Available within 7 days.

- –Peak Season Lead Time: Up to 45 days.

- –Off-Season Lead Time: Within 33 days, depending on part complexity.

How to Order from HUACHEN Screw

Ready to upgrade your production with HUACHEN’s conical twin screw barrels? Follow our simple Step-by-Step Guide to Order from HUACHEN Screw Barrel.

For inquiries or more information about our PE pipe extruder screw barrels, please contact us.

About HUACHEN Screw

Since 1993, HUACHEN Screw has been a leading manufacturer of conical twin screw barrels in Zhoushan Jintang. We offer a wide range of services, including custom designs and modifications, and our products are trusted worldwide for their durability and efficiency.