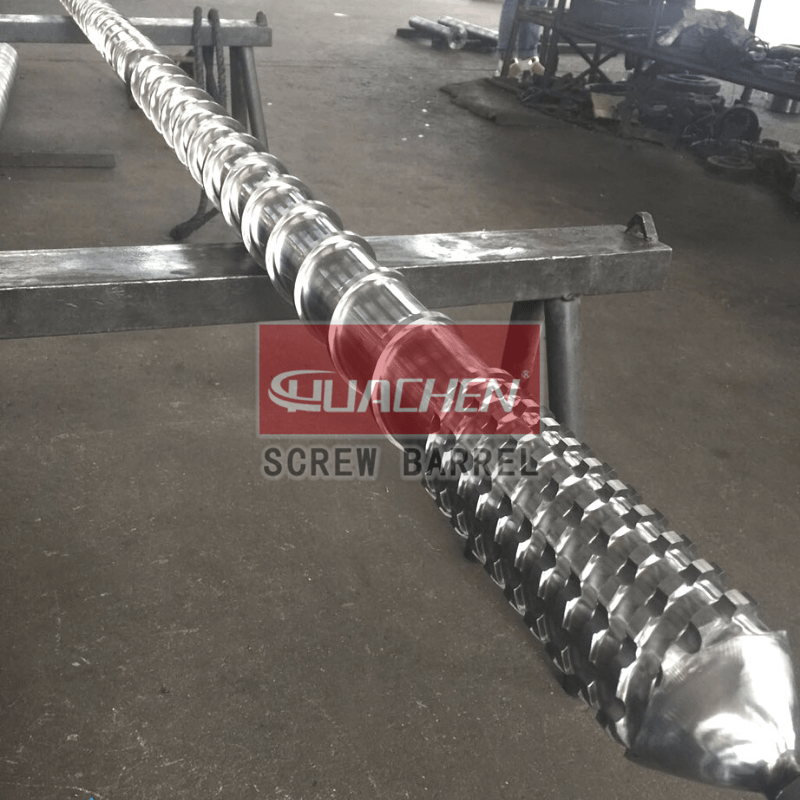

PET Polyester Staple Fiber and Filament Screw Barrel

● PET, PP

● Min. Order (MOQ): 1 screw + 1 barrel

● Plastic filament making. Plastic staple fibre making

● Virgin polyester. Waste or recycled polyester

● Anti-wear solution: Bimetallic barrel + bimetallic screw, nitriding barrel + bimetallic screw, nitriding screw barrel, chrome coating screw

You Need a Better plastic staple fibre and filament extrusion screw barrel at Good Price!

- Product Detail

HUACHEN Screw is specialized in providing PET special screws and barrels for PET extrusion machines employed in polyester filament and staple fibers manufacture. Screw and barrel systems have been designed and developed with high precision and optimization, which in turn will enhance the quality of the PET extrusion line.

Why Choose HUACHEN’s PET Extruder Screw Barrels?

- 1. Premium Materials & Durability: The screws and barrels which we use are produced from high quality 38CrMoAlA steel. Subsequently, our screw barrels are tempering, nitridding, and elaborately machined so that they possess the highest level hardness, wear, and durability. This helps to give your extrusion systems longer service life so they will give you reliable service for a longer period.

- 2. Precision CNC Machining: Our screw barrels are made from high quality screw milling machines, CNC screw milling machines to be precise. Whether you are extruding PET filament or staple fibers, screws and barrels give you consistent, high-quality performance – both required for producing your product.

- 3. Wide Range of Large Screw Barrels: HUACHEN Screw can provide large screw barrels for PET filament, staple fiber and monofilament extrusion, and it has the ability to provide large quantity screw barrels for our customers. These include D90, D105, D120, D160 and D170 and the company is in a position to meet big production line needs offering high output solutions.

- 4. Optimized Screw Design for PET Processing: It also includes both the conventional three-stage screws and unique mixed screws designed for PET filament and staple fiber applications. These advanced designs feature: 1) An improved feed section for stable feed flow and evenly distributed production. 2) Increased the screw melting and compression time to ensure sufficient melt and compression of PET material. 3) Enhanced mixing efficiency of the PET filament and fiber so that the final products contains the right density and quality.

- 5. Screw Barrels for Recycled PET Processing: For clients using recycled PET bottle flakes or sheets, we have developed special screws suitable for recycling processes. These screws in conjunction with bimetallic alloy treatment and optional electroplating provide the highest quality for transparent PET processing, increasing material purity and performance.

- 6. Customizable and Easy to Install: These screw barrels are suitable for most kinds of extruder and the design of them allows for simple assembly. If you do not know your exact needs, our engineers are always willing to help you with personalized screw barrel needs depending on the general assembly details or production specifications you provide.

Applications of PET Polyester Staple Fiber and Filament Screw Barrel

- –Polyester PET staple fiber extruder

- –Polyester PET filament fibre extruder

- –Virgin PET fiber making

- –Recycled PET fiber making

- –PET bottle flakes/sheets to fiber manufacturing

- –PET fibre sheet making machine

Premium Materials

- –Extrusion Single Screw diameter available: Φ45mm to Φ200mm

- –Extrusion Single Screw L/D ratio available: 25 to 30

- –Extrusion Single Screw Max. Length: ≤10000mm

- –Extrusion Barrel Max. Out Diameter: ≤350mm

- –Core Materials: Premium 38CrMoAlA, SKD11, SKD61

- –Plasma Nitriding Surface Hardness: HV1000-1100

- –Plasma Nitriding Depth: ≥ 0.7 mm

- –Nitriding Fragility: Less than Grade I

- –Surface Roughness: Ra 0.4 μm

- –Feed Screw Linearity: ≤ 0.015mm

- –Alloy Depth: 4-6mm, 6-10mm

- –Alloy Surface Hardness: ≥HRC61

For detailed parameters, visit our PET polyester staple fiber and filament screw barrel parameters.

Production time

Complete set of PET polyester staple fiber and filament screw barrel within 20 to 30 days depending on the complexity of the part.

Learn More About Our Other Products

- –Conical Twin Screw Barrel

- –Parallel Twin Screw Barrel

- –High-Speed Extrusion Screw Barrel

- –Extrusion Single Screw Barrel

We also offer a comprehensive range of extruder accessories to complement our screw barrels, including heaters, flanges, and gearboxes.

How to Order from HUACHEN Screw

Ready to upgrade your production with HUACHEN’s conical twin screw barrels? Follow our simple Step-by-Step Guide to Order from HUACHEN Screw:

- 1. Contact Us: Reach out to our sales team via email or phone.

- 2. Specify Requirements: Provide detailed specifications and requirements for your project.

- 3. Receive a Quote: Our team will provide a customized quote based on your needs.

- 4. Place an Order: Confirm the order and provide necessary payment details.

- 5. Production and Delivery: We will manufacture your order and arrange for timely delivery.

For inquiries or more information, please contact us.

About HUACHEN Screw

HUACHEN Screw has been specialized in the production of PET polyester staple fiber and filament screw barrel in Zhoushan Jintang since 1993. The screw barrel is the key component of filament and staple fibre extruder spare parts and we specialise in drawing rebuilding, design, modification and even bespoke screw barrels. They use our products to get the best of both durability and efficiency to the world. Contact HUACHEN Screw now to get the right guidance and the appropriate solution to your PET extrusion machine.