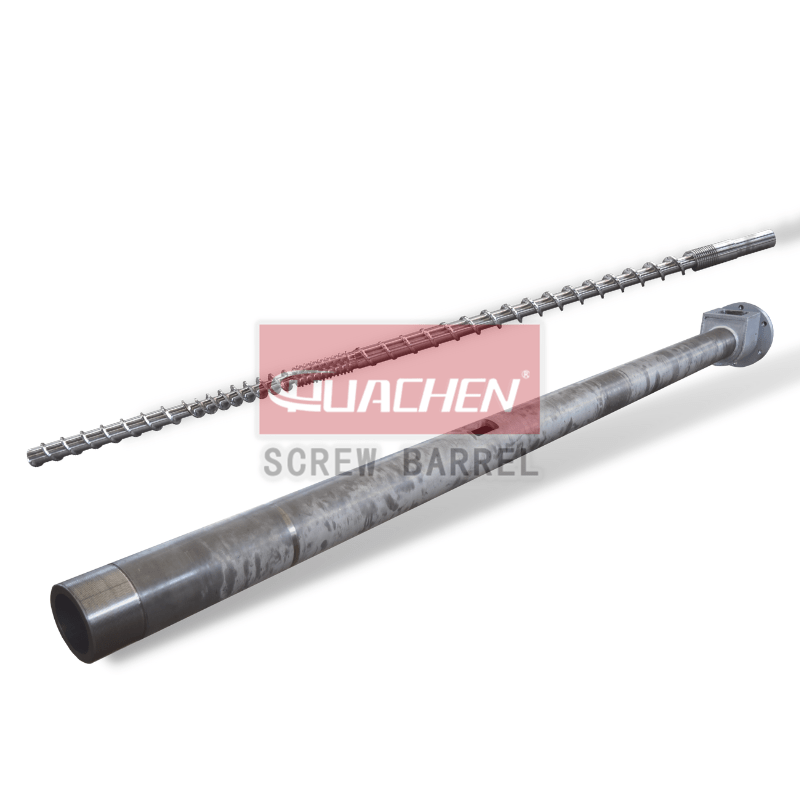

PET Recycled Polyester Staple Fibre Screw Barrel

● Min. Order (MOQ): 1 screw + 1 barrel/Set

● PET/PP recycling polyester staple fibre, polyester yarn, PET Sheets, PET box packing, PET preforms and recycled PET resin

● Conventional screw barrel

● Vented screw barrel

● Three-stage screw with mixing head(the pineapple)

You Need Better PET Recycled Polyester Staple Fibre Screw Barrel at Good Price!

- Product Detail

HUACHEN Screw has been a top producer of PET recycled polyester staple fibre screw barrel in Zhoushan Jintang since 1993. With many years of experience designing and processing resin recycling extruder screw barrels, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customization. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn more about our company

PET recycled polyester staple fibre RPSF screw barrel

The PET polymer resin is a well-known thermoplastic polymer. As a component of fibres, it is used in clothing, thermoformed products, food, and liquid containers. Polyester staple fibre (RPSF) is a common fibre in the textile industry, and it plays a crucial role in PET plastic recycling.

HUACHEN Screw manufactures PET recycled polyester staple fibre screw barrels from high quality 38CrMoAlA. The material used for screw barrels has been rigorously tempered and nitrided. As PET has a low viscosity, a high specific heat capacity, a tendency to stick to itself, and a need for fast and uniform plasticization, our PET screw is optimized for these characteristics.

PET recycled polyester staple screw has an aspect L/D ratio of 32 or more, which ensures sufficient extrusion pressure and plasticization. You can choose from a wide range of screw configurations, including the conventional single screw and three-stage screw with mixing head(the pineapple), or we can design the screw configuration custom-made for you.

For PET recycled material with many impurities, we offer vented screw barrels. Through the venting port, the vented barrel discharge gaseous impurities, reducing the need for drying and ensuring product quality.

Application of PET recycled polyester staple fibre screw barrel

Remelting thermoplastic PET bottles, bags, or packaging melts the thick material, which is then extruded into fibres. It is possible to produce fibres in large quantities and then spin them into fine yarns of the desired length.

We can customise special screw according to your drawings. In the event that you cannot confirm the design of your screw barrel, we can recreate a screw barrel drawing based on the rest of your existing extruder assembly.

Parameters

1. Single screw diameter available: 45 mm to 200 mm

2. Single screw L/D ratio available: 15 to 40

3. Screw max. length: ≤10000 mm

4. Barrel max. out diameter: ≤350 mm

5. Based materials: Premium 38CrMoAlA (UNS K24065, SACM645, 41CrAlMo7-10)

6. Nitriding surface hardness: HV 1000-1100

7. Nitriding depth: ≥ 0.7 mm

8. Nitriding fragility: less than Grade I.

9. Surface Roughness: Ra 0.4 μm

10. Screw Linearity: ≤ 0.015mm

11. Alloy depth: 2-4 mm

12. Alloy surface hardness: ≥ HRC 61

>>Learn more about our PET recycled polyester staple fibre screw barrel parameters

The ultimate solution for abrasion and wear

1.Alloy steel of high strength, tempered and nitride.

2.bimetallic alloy screw: Plasma alloy coating spraying with nickel-based and molybdenum-based alloys on vulnerable screw parts with a thickness of 1 to 1.5 mm. Effectively provide 1.5 times longer service life.

3. screw with hard chrome plating as optional process.

4. bimetallic barrel: grooved feed sleeve process

5. bimetallic barrel: centrifugal casting alloy base process.

>>Learn more about our bimetallic alloy screw barrel treatments

Production time

Complete set of PET recycled polyester staple fibre screw barrel within 33-40 days depending on the complexity of the part.

We have a wide selection at good prices to help you get creative. High quality PET recycled polyester staple fibre screw barres are available for sale. We are the China Origin Factory of grooved feeding barrel. If you have any questions, please feel free to contact us.