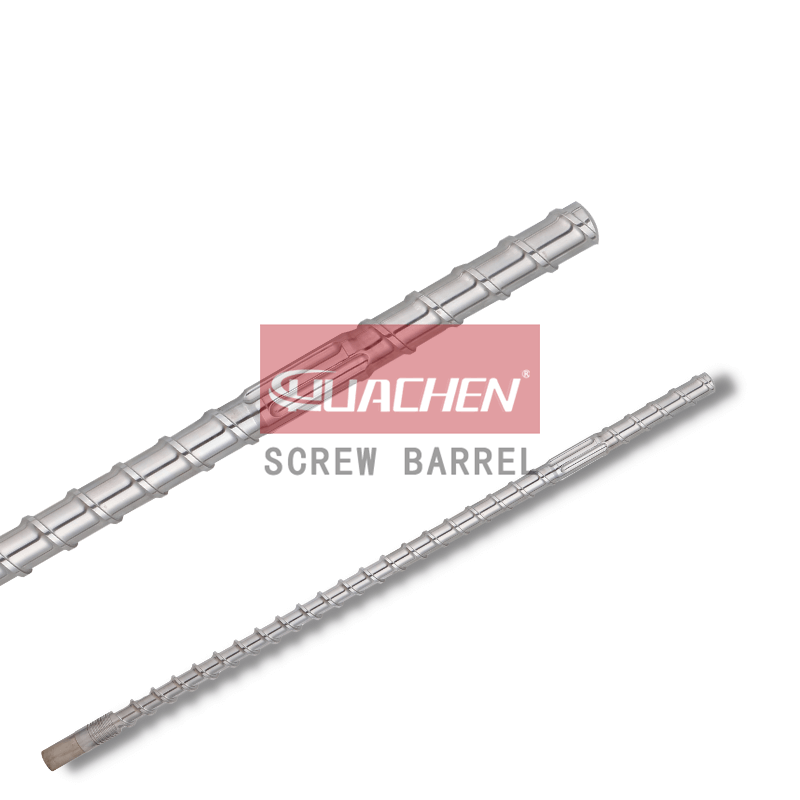

PP PA Plastic Filament Spinning Extruder Screw Barrel

● PP, PA, PA6, PA66, etc.

● Min. Order (MOQ): 1 screw + 1 barrel

● Plastic filament yarn making. Monofilament making. Multifilament making

● Fresh raw materials. Recycled raw materials

● Anti-wear solution: Bimetallic barrel + bimetallic screw, nitriding barrel + bimetallic screw, nitriding screw barrel, chrome coating screw

You need a better plastic filament spinning extruder screw barrel at good price!

- Product Detail

It’s the China original factory for PP PA filament spinning extruder screw barrel. The plastic filament spinning extruder screw barrel is the core component of the PP PA filament spinning machine. PP PA filament products’ performance and quality are determined by screw and barrel design and the strength of their materials.

Quality PP PA Plastic Filament Spinning Extruder Screw Barrel

1. The screw and barrel are made from premium 38CrMoAlA. Processes using strict tempering and nitriding, the hardness of the screw barrel and various indicators of durability, allowing a longer service life. The screw and barrel are all machined using high precision CNC screw barrel milling machines. Each set of screw barrels has a high degree of consistency in extrusion.

2. We offer three-stage filament spinning extruder screws and combination screws special for PP PA filament as well. The screw and barrel feed section structure was optimized for stable feed and balanced output in the extrusion section, boosting plasticisation and extrusion efficiency. The melt will be compressed by increasing the melting and compression time. Plastic filament yarn will be more dense and well mixed by this way, ensuring quality.

3. Screw barrels fit most filament spinning machine models and are easy to install. You can also provide assembly information to our engineers for customizing your screw barrel.

Applications

Plastic fibre spinning processes. Single screw barew for PP mono-filament Extruder, PA6 monofilament Extruder, PA66 staple fibre extruder, filament yarn and staple fibre extrusion machine.

Manufacture of filament spinning extruder screw barrel model

| Model | Screw diameter (mm) | L/D ratio | Screw speed Max. (rpm) | Motor required (KW) | Output (Kg/h) |

|---|---|---|---|---|---|

| HCS45 | Ф45 | 25/28/30 | 20-90 | 7.5 | 38 |

| HCS65 | Ф65 | 25/28/30 | 20-90 | 18.5 | 78 |

| HCS80 | Ф80 | 25/28/30 | 20-80 | 37 | 115 |

| HCS90 | Ф90 | 25/28/30 | 20-80 | 45 | 196 |

| HCS105 | Ф105 | 25/28/30 | 20-70 | 55 | 295 |

| HCS120 | Ф120 | 25/28/30 | 20-60 | 75 | 390 |

| HCS135 | Ф135 | 25/28/30 | 20-60 | 90 | 535 |

| HCS150 | Ф150 | 25/28/30 | 20-60 | 110 | 652 |

| HCS160 | Ф160 | 25/28/30 | 20-60 | 132 | 705 |

| HCS170 | Ф170 | 25/28/30 | 20-60 | 160 | 850 |

| HCS180 | Ф180 | 25/28/30 | 20-50 | 185 | 972 |

| HCS200 | Ф200 | 25/28/30 | 20-50 | 200 | 1050 |

*Please check the actual screw barrel design with the salesperson before the order start.

Filament spinning extruder screw barrel for the Following plastic machine brands:

Jinhu, Jwell, and China plastic machine brands.

Parameter

1. Material: Premium 38CrMoAlA, UNS K24065, SACM645, 41CrAlMo7-10.

2. Plasma nitriding layer: 0.6-0.8mm

3. Nitriding time: more than 120 hours

4. Nitriding surface hardness: HV1000-1100

5. Nitrided Brittleness: Less than Grade1

6. Surface Roughness: Ra 0.4μm

7. Screw Linearity: ≤0.015mm

8. Alloy surface hardness: HRC≥61

9. Alloy deepness: 4-6mm

>>Learn more about our PP PA plastic filament spinning extruder screw barrel parameters

The ultimate solution for abrasion and wear

1. Bimetallic barrel + bimetallic screw,

2. Nitrding barrel + bimetallic screw

3. Nitriding barrel + nitriding screw

Related PP PA filament spinning extruder screw barrel spare parts

1. Extrusion heaters. 2. Barrel blowers or fans. 3. Extrusion motor. 4. Extrusion gearbox for single screw

Trading Term

1. Business type: manufacturer, foreign trade company.

2. Origin: Zhoushan City, Zhejiang, China

3. Warranty: 12 months for fresh material.

4. International Commercial Terms: FOB, CFR, CIF, EXW

5. Screw and barrel Hs Code: 8477900000

6. Terms of Payment: T/T, L/C

7. Average Lead Time: stork model in 7 days. Peak season lead time: 45 days, Off season lead time: 33 days

8. Transport package: AA Grade Wooden Case

PP PA filament spinning extruder screw barrel services

1. Provide the diameter of the screw → provide the total length of the screw → provide the screw pitch size and material information → HUACHEN Screw produces CAD drawings → customer confirms the drawings → arrange production after confirming the accuracy → delivery.

2. Providing OEM or ODM quality rebuilding services.

3. Services to improve the melting and mixing performance of screw designs.

4. You can get an emergency turnaround service to minimize machine downtime.

About us

HUACHEN Screw has been a leading manufacturer of PP PA filament spinning extruder screw barrel services in Zhoushan Jintang since 1993. As one of the leading companies in designing and processing plastic filament and yarn machinery replacement parts, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customized screw barrels. Our company has also successfully exported and supplied screw barrels to customers worldwide. >>Learn more about our company It’s the China Original Factory for PP PA filament spinning extruder screw barrel services. If you have any questions, please feel free to contact us.