Principle of UPVC Profile Formulation Composition and Adjustment

Date:2023-2-05 Author:hcscrew

Description: Learn the principles of UPVC profile formulation and how to make adjustments for optimal results. Explore the science behind UPVC profile manufacturing and discover how to optimize your formulation for improved performance.

PVC profiles and pipes are common products in everyday life. UPVC pipes, profiles, and sheets are not manufactured from a single raw material but from various raw materials in different ratios. Therefore, every company has its unique and optimized recipe. As a UPVC manufacturer, understanding the composition of these raw materials, their ratios, and the plasticization principles is crucial. Furthermore, you need to adapt them to your production conditions. With years of experience as a UPVC profile screw barrel manufacturer, we’ve compiled this article to help you. If you have questions or need our screw barrels for UPVC profiles, please contact us.

UPVC Profile Raw Material Formulation Composition

1. PVC Resin

Extruded UPVC rigid products are typically made with suspension-process resins. Ensure the resin has the appropriate polymerization, particle size, and looseness. Avoid using resins with large particle sizes and tightly packed particles.

2. Stabilizers

PVC resin is heat-sensitive and begins to degrade at temperatures between 90-130°C, shedding unstable HCL, and turning yellow. Adding stabilizers to PVC resin helps prevent degradation by absorbing and neutralizing HCL gas. Common stabilizers include lead salts, organotins, metal soaps, and rare earth stabilizers.

3. Lubricants

Lubricants improve lubricity by decreasing interface adhesion. There are three types: external, internal, and internal/external. External lubricants decrease friction between the material and the metal surface, while internal lubricants lower the viscosity of the melt. The right lubricant can significantly reduce screw load, shear heat, and increase extrusion output.

4. Filling Materials

Fillers like CaCO3 increase hardness, rigidity, and reduce deformation and raw material costs in UPVC products.

5. Processing Modifier (ACR)

Processing modifiers accelerate PVC resin plasticization, improve material flow, heat deformation, gloss, and other product characteristics.

6. Impact Modifier

Common impact modifiers for UPVC include CPE (chlorinated polyethylene) and propylene glycol.

7. Colouring Agents

Common coloring agents include titanium dioxide and carbon black.

Effects of Plasticization on Counter-Rotating Twin Screw Extruders

1. PVC Resin

Different PVC resins have varying polymerization, powder structures, and bonding strengths between micro-particles. Resins with thinner surface layers and looser particles are easier to melt and produce better quality products.

2. Stabilizers

Stabilizers affect material deformation and melting in extrusion. The type and amount of stabilizer should be determined by the extruder and die used. Conical twin screw barrels, counter-rotating parallel twin screw barrels, and single screw barrels require different stabilizer dosages due to their structural differences and shear strengths.

3. Lubricants

Lubricants influence the melting time, speed, screw load, extrusion output, head pressure, and mechanical properties of the material. Internal lubricants reduce melt viscosity, while external lubricants decrease the shearing effect, prolonging melting time. The right balance is crucial for effective plasticization.

4. Fillers

Fillers like calcium carbonate and talc can play auxiliary stabilizing and external lubricating roles. The surface activity of fillers affects the lubricity and stability of the material during melting.

5. Modifiers

ACR and CPE impact modifiers increase the material’s melting and torque, affecting yield and plasticization time. The correct dosage is crucial for optimal extrusion performance.

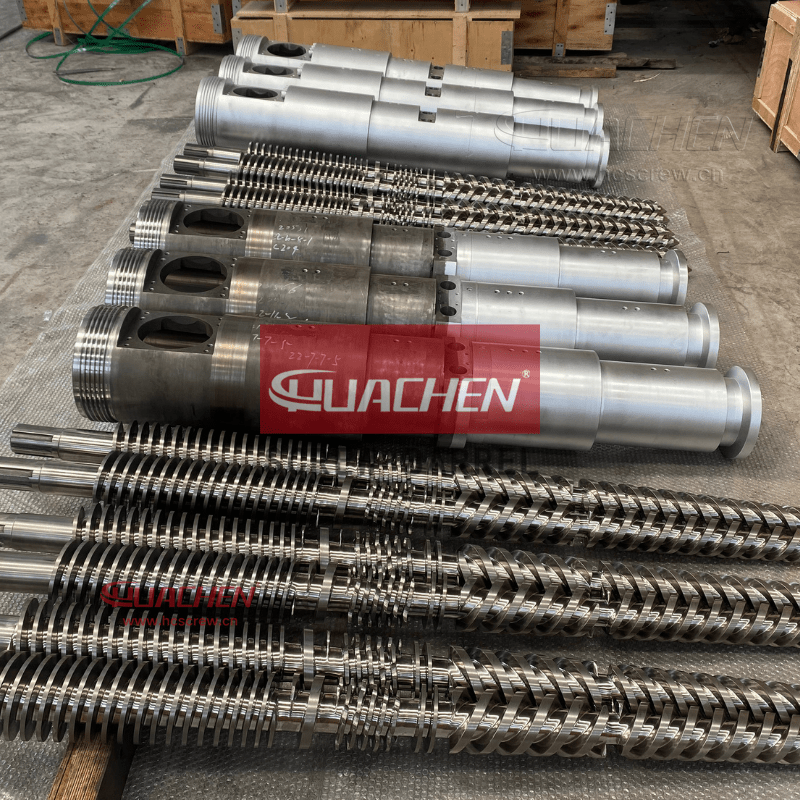

About HUACHEN Screw

Since 1993, HUACHEN Screw has been a leading UPVC screw barrel manufacturer in Zhoushan Jintang. As experts in designing and processing twin screw barrels and high-speed extruder screw barrels, we offer a wide range of services, including design, modification, and customized screw barrels. We have successfully exported and supplied screw barrels to customers worldwide.

For more information on how HUACHEN Screw can help you optimize your UPVC profile formulations and improve your extrusion processes, visit our website.

You May Also Like

| PVC Profile Extrusion Screw Barrel ↗ Get details and quotes for PVC profile extrusion screw barrels. We offer a wide variety of anti-wear screw barrels for many profile extrusions. |

| RPVC, CPVC, UPVC Screw Barrel ↗ Get details and latest price of RPVC, CPVC, UPVC PVC screw barrel, high-speed design, better anti-wear anti-corrosion screw barrel at HUACHEN. |

| 25 PVC Pipe And Other PVC Products Making Formulas ↗ Introduce 25 typical PVC product formulas in PVC extruding process. Such as PVC pipe, PVC panel production formula, PVC sheet, PVC profile. |

By understanding the principles of UPVC profile formulation and making the necessary adjustments, you can significantly enhance the performance and quality of your products. For expert advice and high-quality screw barrels, HUACHEN Screw is your trusted partner. Contact us today to discuss your specific needs.

Tags

HUACHEN Screw Recent Post

- High-performance PVC Screw Barrel for Efficient Extrusion

- Durable Conical Twin Screw Barrel for Precision PVC Pipe Production

- High-Speed Screw Barrel for Increased Extrusion Efficiency

- Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders

- High-Precision Parallel Twin Screw Barrel for Extrusion Excellence

- Top Quality Single Screw Barrels for Plastic Extrusion Applications

- High-quality Extruder Screw Barrel for Reliable Performance

- Efficient Plastic Extrusion Screw Barrel for Superior Output

Tag Clound

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;