PVC Compound Pelletizing Machine Conical Twin Screw Barrel

● PVC / PE / PP / PA, virgin or recycled materials

● Filler ratio of 100-200%, 200-300%, and greater than 300%.

● Min. Order (MOQ): 2 conical screws + 1 barrel

● Based material: Premium 38CrMoAlA tempered and nitrided, SKD11

● Anti-wear solution: SKD sleeve fitted barrel + bimetallic screw, bimetallic barrel + bimetallic screw, chrome coating screw, ceramic alloy screw

You Need Better Conical Twin Screw Barrel at Good Price!

- Product Detail

We offer a conical twin screw barrel for PVC compound granulating and pelletizing machine. It is possible to achieve 1. Making high filled granules or pellets for PVC and PE. 2. Recycling scraps and offcuts from soft plastic films, bags, filaments, strips, sheets, and pipes like PVC, PP, LDPE, HDPE, LLDPE, etc. 3. Recycling degraded plastic films and corners. 4. Recycle PE, PA, PP fibres to crush and pelletize for waste yarn reproduction. 5. Multiple uses for one machine. You can use it instead of mixers or dryers.

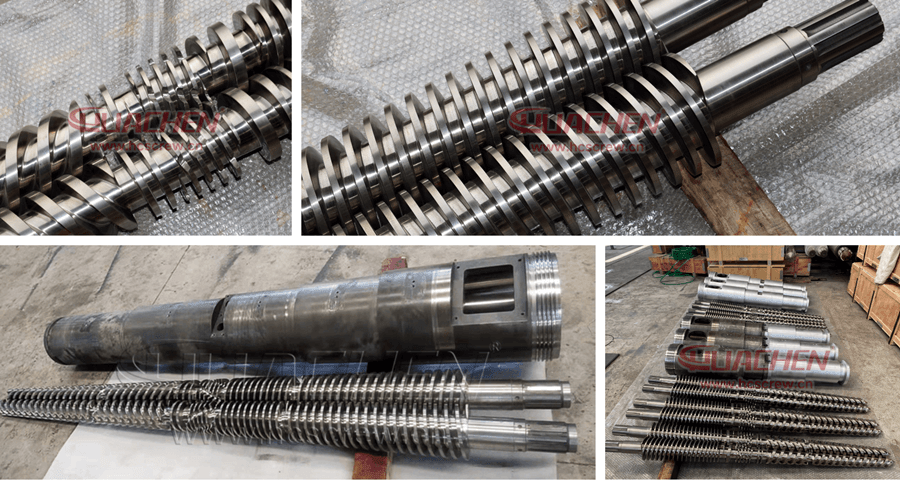

PVC compound pelletizing machine conical twin screw barrel

1. All conical twin screw barrels were machined on a high-precision CNC screw mill. Each screw barrel set has a high degree of consistency in extrusion performance. Smooth screw and barrel surfaces keep material from sticking.

2. Conical twin screw barrel with low shear and high conveying design for stable extrusion pressure and good plasticizing and mixing. It allows you to crush, mix, and color primary raw materials all at once.

3. Optimized conical twin screw design for pelletizing at low temperatures. There is basically no damage to the molecular structure or physical properties of the raw material. Granules or pellets are well plasticized and have stable quality.

4. The barrel has a vent port that allows a good amount of venting. Excellent plasticization allows you to make high-filled compound granules or pellets.

5. The screw and barrel are protected from corrosion and wear with practical solutions.

6. We offer both standard and new high efficiency conical twin-screw barrel models. They’re all easy to assemble and install. Depending on the region and country, we have different conical twin screw barrel designs. For more info, contact us.

Application

PVC high filled granulating or pelletizing machine

PE high filled granulating or pelletizing machine

PVC, PP, LDPE, LLDPE, HDPE recycling pelletizing machine

Waste PE, PP film and offcut recycling pelletizing machine

Waste PE, PA, PP staple and filament fibre recycling pelletizing machine

Manufacture of PVC compound pelletizing machine conical twin screw barrel

| Model | Screw speed (RPM) | Motor (KW) | Capacity (kg/h) | Screw length (mm) | Barrel length (mm) | Weight (kg) | Package dimension (m) |

|---|---|---|---|---|---|---|---|

| HCZS 80/156 | 34.7 | 55 | 500 | 2116 | 1850 | 775 | 2.2*0.4*0.5 |

| HCZS 92/188 | 34.7 | 110 | 800 | 2805 | 2520 | 1500 | 3.0*0.5*0.6 |

Parameters

1. Material: Premium 38CrMoAlA, UNS K24065, SACM645, 41CrAlMo7-10, SKD11.

2. Plasma nitriding layer: 0.6-0.8mm

3. Nitriding time: more than 120 hours

4. Nitriding surface hardness: HV1000-1100

5. Nitrided Brittleness: Less than Grade1

6. Surface Roughness: Ra 0.4μm

7. Screw Linearity: ≤0.015mm

8. Alloy surface hardness: HRC≥61

9. Alloy deepness: 4-6 mm

10. SKD sleeve surface hardness: HRC≥62

11. SKD sleeve thickness: 6-10mm

>> Learn more about our PVC compound pelletizing machine screw barrel parameters

Related Conical twin screw extrusion screw barrel spare parts

| Confluence core or adaptor | Big nut or barrel big neck | Barrel haf neck | Extruder machine frame |

| Striker plate | Couplings | Vacuum seat | Hopper |

| Extruder heaters | Blowers or fans | Extruder motor | Extruder gearbox |

>> Learn more about our twin extrusion spare parts available.

Production time

Complete set of PVC compound pelletizing machine conical twin screw barrel within 20-40 days depending on the complexity of the part.

HUACHEN Screw has been a leading conical twin screw barrel manufacturer in Zhoushan Jintang since 1993. As one of the leading companies in designing and processing conical twin screw extrusion spare parts screw barrels, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customized screw barrels. Our company has also successfully exported and supplied screw barrels to customers worldwide. We are the China origin factory of PVC compound granulating pelletizing machine conical twin screw barrel. If you have any questions, please feel free to contact us.