PVC Siding and Wall Panel Extrusion Screw Barrel

● PVC / UPVC / RPVC / WPC

● Filler ratio of 0-100, 100-200%, 200-300%, and greater than 300%.

● Min. Order (MOQ): 2 conical screws + 1 barrel

● Based material: Premium 38CrMoAlA tempered and nitrided, SKD11

● Nitriding surface hardness: HV≥1000

● Nitriding depth: ≥ 0.7mm

● Anti-wear solution: SKD sleeve fitted barrel + bimetallic screw, bimetallic barrel + bimetallic screw, chrome coating screw, ceramic alloy screw

You Need Better Conical Twin Screw Barrel at Good Price!

- Product Detail

HUACHEN Screw offers high-quality PVC siding and wall panel extrusion screw barrels. Our expertly engineered conical twin screw barrels ensure efficient and precise extrusion for your PVC siding and wall panel production needs. Shop now and experience the difference in quality and performance!

What is PVC siding and wall panel?

PVC siding and wall panels, made from PVC as the raw material, is light, easy to install and waterproof, moisture-proof, moth-proof, easy to clean and resistant to pollution, offering good sound insulation and heat insulation, especially due to the addition of flame retardant materials.

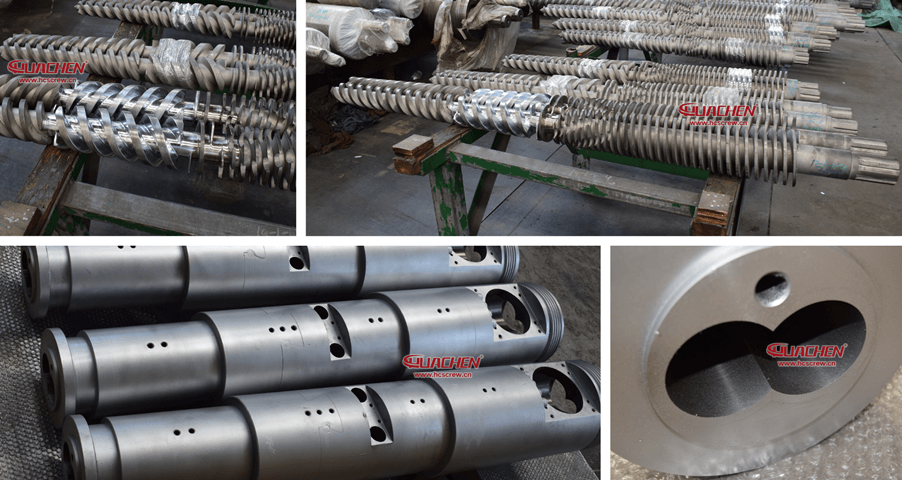

PVC Siding and Wall Panel Extrusion Screw Barrel

HUACHAN Screw provides optimized extruder screw barrels for PVC siding and wall panels.

1. PVC powder can be directly extruded. Compared to granular raw materials, it uses less energy.

2. The PVC siding and wall panel extruder twin screw has a low shear, efficient conveying design to increase extrusion capacity. Siding and wall panels can be produced with solid, thick, or oversized walls. The screw and barrel are machined using high precision CNC screw milling machines. It ensures high levels of consistency in extrusion performance from one set of PVC siding screw barrels to the next. The surface of the screw and barrel is smooth and free of gaps to avoid material build-up.

3. We offer different screw designs for PVC panel formulations. Filling ratios of 100-200%, 200-300%, and greater than 300% can be applied.

4. The screws and barrels are designed to resist corrosion and wear.

5. The screw is equipped with a self-regulating oil-free closed temperature system for precise temperature control and easy maintenance.

6. Excellent compatibility. For PVC siding extruders, we offer mainstream and new high-efficiency conical twin screw barrel models such as SZ48/118, SZ53/128, SZ65/132, and SZ80/156. They all use standard assembly dimensions and are easy to install. Based on the region and country, we have fine-tuned barrel designs for PVC siding and wall panels. If you would like to learn more about our specifications, please do not hesitate to contact us.

Application

PVC wall panels, PVC siding, wood veneer siding, WPC composite wall panels, PVC buckle board, faux stone or marble wall panels, etc.

Manufactures of PVC siding and wall panel extrusion screw barrel

| Model | Screw speed (rpm) | Motor (kW) | Capacity (kg/h) | Screw length (mm) | Barrel length (mm) | Weight (kg) | Package dimension (m) |

|---|---|---|---|---|---|---|---|

| HCZS48/118 | 34.7 | 18.5 | 80-150 | 1236 | 1130 | 196 | 1.3*0.3*0.4 |

| HCZS51/105 | 34.7 | 22 | 80-150 | 1183 | 1070 | 196 | 1.3*0.3*0.4 |

| HCZS53/128 | 34.7 | 22 | 80-150 | 1430 | 1230 | 286 | 1.5*0.3*0.4 |

| HCZS55/110 | 34.7 | 22 | 80-150 | 1430 | 1230 | 286 | 1.5*0.3*0.4 |

| HCZS65/132 | 34.7 | 37 | 150-250 | 1701 | 1480 | 410 | 1.8*0.3*0.4 |

| HCZS65/138 | 34.7 | 37 | 150-250 | 1701 | 1480 | 410 | 1.8*0.3*0.4 |

| HCZS80/156 | 34.7 | 55 | 300-400 | 2116 | 1850 | 775 | 2.2*0.4*0.5 |

>> Please check the actual conical twin screw barrel design with the salesperson before the order starts.

Parameter

1) Material: Premium 38CrMoAlA, UNS K24065, SACM645, 41CrAlMo7-10, SKD11. 2) Plasma nitriding layer: 0.70 mm. 3) Nitriding time: more than 120 hours. 4) Nitriding surface hardness: ≥HV1000. 5) Nitriding Brittleness: Less than Grade 1. 6) Surface Roughness: Ra 0.4μm. 7) Screw Linearity: ≤0.015 mm. 8) Alloy surface hardness: HRC≥61. 9) Alloy deepness: 1.5 mm. 10) SKD sleeve surface hardness: HRC≥62. 11) SKD sleeve thickness: 6-10mm

>> Learn more about our PVC siding and wall panel screw barrel parameters

The ultimate solution for abrasion and wear

Level 4: SKD sleeve fitted barrel and ceramic alloy coating screws;

Level 3: SKD sleeve fitted barrel and hard chrome coating screws;

Level 2: SKD sleeve fitted barrel and bimetallic screws;

Level 1: bimetallic barrel and bimetallic screws;

Related PVC profile extrusion screw barrel spare parts

| Converging die for extruder machine, merging core or adaptor | Big nut or barrel big neck | Barrel haf neck | Extruder machine frame |

| Striker plate | Couplings | Vacuum seat | Hopper |

| Extruder heaters | Blowers or fans | Extruder motor | Extruder gearbox |

>> Learn more about our twin extrusion spare parts available.

Trading Term

1. Business type: manufacturer, foreign trade company.

2. Origin: Zhoushan City, Zhejiang, China

3. Warranty: 12 months for fresh material.

4. International Commercial Terms: FOB, CFR, CIF, EXW

5. PVC screw barrel Hs Code: 8477900000

6. Terms of Payment: T/T, L/C

7. Average Lead Time: Average Lead Time: Ready stock model within 7 days, and custom-made model within 30 days depending on the complexity of the part.

8. Transport package: AA Grade Wooden Case

PVC siding and wall panel extrusion screw barrel service

1. Examine the original PVC siding and wall panel extrusion screw barrel and other associated spare parts.

2. Rebuilding services in accordance with OEM specifications. Provide a screw design suitable for PVC wall panel products.

3. Screw design modification services to improve melting and mixing performance

4. Emergency Service for an emergency turnaround service to minimise machine downtime.

About us

HUACHEN Screw has been an outstanding manufacturer of PVC siding and wall panel extrusion screw barrel in Zhoushan Jintang since 1993. With many years of experience in designing and processing plastic machinery replacement parts, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customization. Our company has also successfully exported and supplied screw barrels to PVC siding and wall panel manufacturers worldwide. Our screw barrels are one of the most popular products for PVC wall panels and decorative materials in Haining, China. >>Learn more about our company