Screw Barrel For PVC Processing: FAQ and Solutions

Date:2022-6-29 Author:hcscrew

Q1: My pipe processing screw barrel isn’t feeding material or the current is seriously unstable.

A1. In some cases, the screw lead has been damaged due to poor control or the lead section spacing has been narrowed so that it does not meet the requirements.

A2. The conical twin screw design does not correspond to the actual ratio used for calcium powder in PVC processing. We suggest replacing the screw with one that is suitable for coarser calcium powder meshes, or changing the screw structure altogether.

A3. There is a problem with the screw reflux section shear capacity, or the depth of the reflux C-shaped slot is insufficient.

A4. The host extruder is running at an excessive speed.

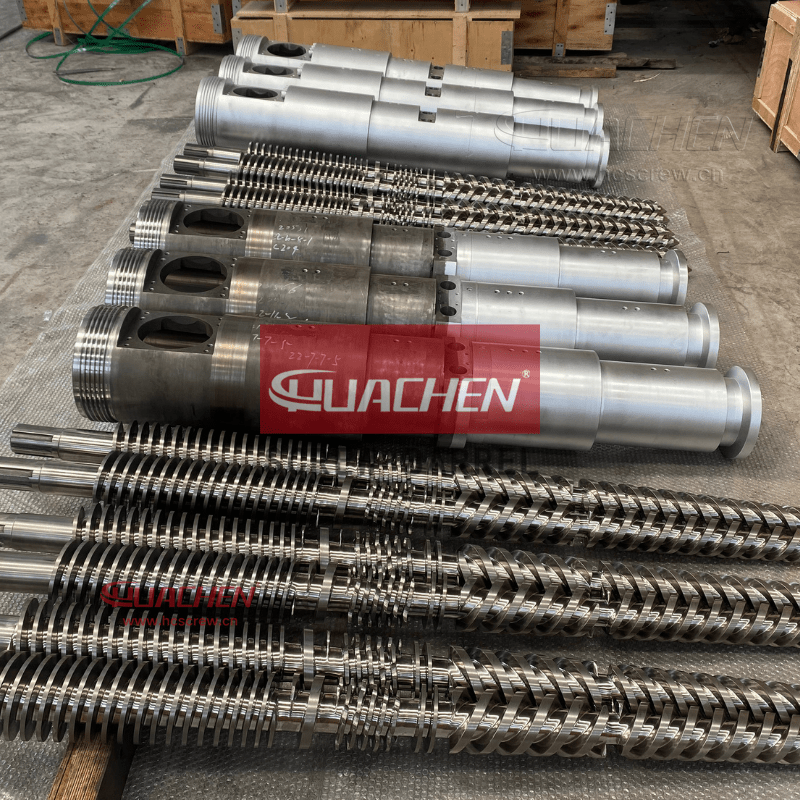

Q2: There is a serious wear problem with conical twin screws.

A1. The nitriding layer depth of the conical twin screws is seriously inadequate. It is not good enough that the screw barrel manufacturer nitrites their screws.

A2. In the second section, the conical twin screw is seriously worn. There is too much moisture in calcium powder, or the plasticizing temperature is too low. If the moisture content of calcium powder exceeds a certain level, similar problems may occur.

A3. There is a serious wear problem in the third section of the conical screw. This problem is generally associated with the use of extruder screws for abrasive materials. You may replace this screw with a more wear resistant bimetallic screw barrel, or use HUACHEN’s SKD sleeve fitted barrels that are specifically designed for such situations.

A4. The conical screw has severe wear in the fourth section.

Calcium powder proportion and mesh size play an important role in calculating the wear level at the fourth section of a conical screw. When using more than 2000 mesh calcium powder and less than 50%, the life expectancy of a conical twin screw barrel is approximately three years. For PVC products processing with a percentage of 50 to 100%, the screw barrel is expected to last approximately two years. The life of a conical twin screw barrel is typically six to ten months if it uses high filling calcium powder. (150 to 300%).

The degree of wear of the conical twin screw barrel is clearly correlated with the amount of calcium powder filling. Therefore, we can use this approach to extend the applicable time for conical twin screws and barrels. The first step is to select the right calcium powder material. We then select the appropriate conical twin screw design based on the amount of calcium powder to be used. To learn more about the durable design of conical twin screws and barrels, please contact us.

Q3. Screw breakage.

As long as it leaves the factory without injury after quality control, all other causes of fracture are man-made, except for screw fractures caused by damage to the extruder parts gearbox (distribution box).

A1. The screw’s second section has a fracture. A sudden suspension or sudden addition of raw materials after the cut-off supply can cause a break between the second and third section. Or screw serious wear. A four-millimeter gap between two conical screws in the fourth section may cause fractures in high-speed production. However, if the current is stable, the screw cannot be broken.

A2. The screw fractured at the beginning of the cold machine’s operation. Upon turning on the machine, the extruder does not reach the required temperature. Slight scorching in the third and fourth sections makes it easy for the screw to break when shut down improperly.

A3. In order to prevent iron trioxide (on rust) from forming on screws or equipment, it is necessary to treat them before production. Otherwise, the screw will fracture.

About us

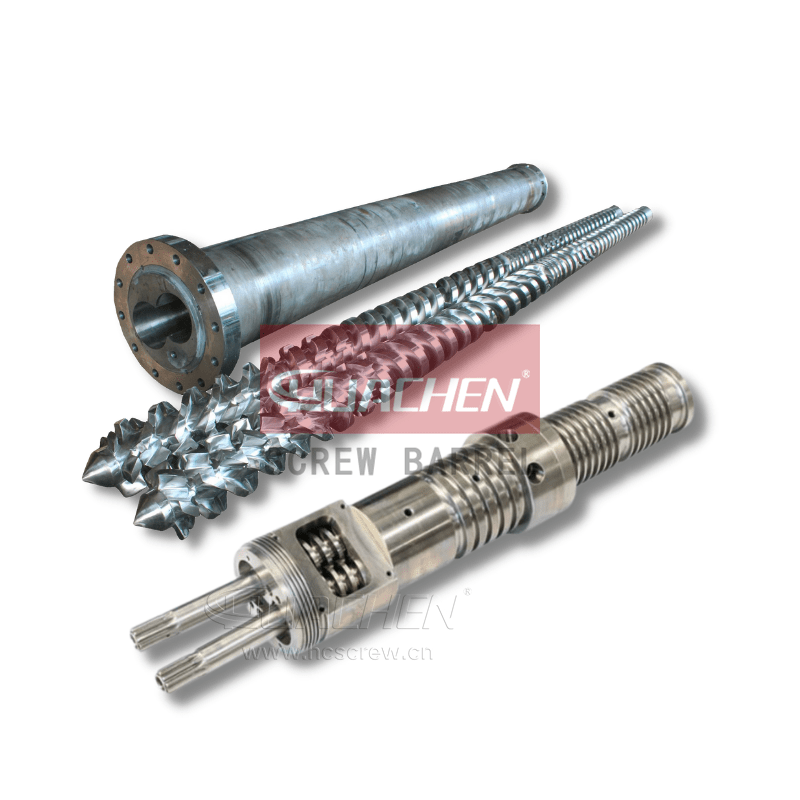

HUACHEN Screw Manufacturing Co., Ltd. is located in the beautiful coastal city of Thousand Islands, Jintang Town, Zhejiang Province, China. It is also the largest plastic and rubber screw and barrel production base in China.

With more than 23 years of experience in plastic chemical engineering, our factory focuses on producing HUACHEN brand SKD screw barrel, bimetallic alloy screw barrel, and more. Plastic extruders, injection moulding machines, and other machines employ the products.

Learn more about the pipe machine screw barrel from HUACHEN Screw Barrel by requesting a quote or contacting us!

YOU MAY ALSO LIKE

| PVC Screw Barrel ↗ Get details and latest price of PVC screw barrel, high output, PVC single, parallel, conical twin screws, advantages, applications at HUACHEN |

| RPVC, CPVC, UPVC Screw Barrel ↗ Get details and latest price of RPVC, CPVC, UPVC screw barrel, high-speed design, better anti-wear and anti-corrosion screw barrel at HUACHEN. |

TAGS

HUACHEN Screw barrel recent post

- High-performance PVC Screw Barrel for Efficient Extrusion

- Durable Conical Twin Screw Barrel for Precision PVC Pipe Production

- High-Speed Screw Barrel for Increased Extrusion Efficiency

- Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders

- High-Precision Parallel Twin Screw Barrel for Extrusion Excellence

- Top Quality Single Screw Barrels for Plastic Extrusion Applications

- High-quality Extruder Screw Barrel for Reliable Performance

- Efficient Plastic Extrusion Screw Barrel for Superior Output

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;