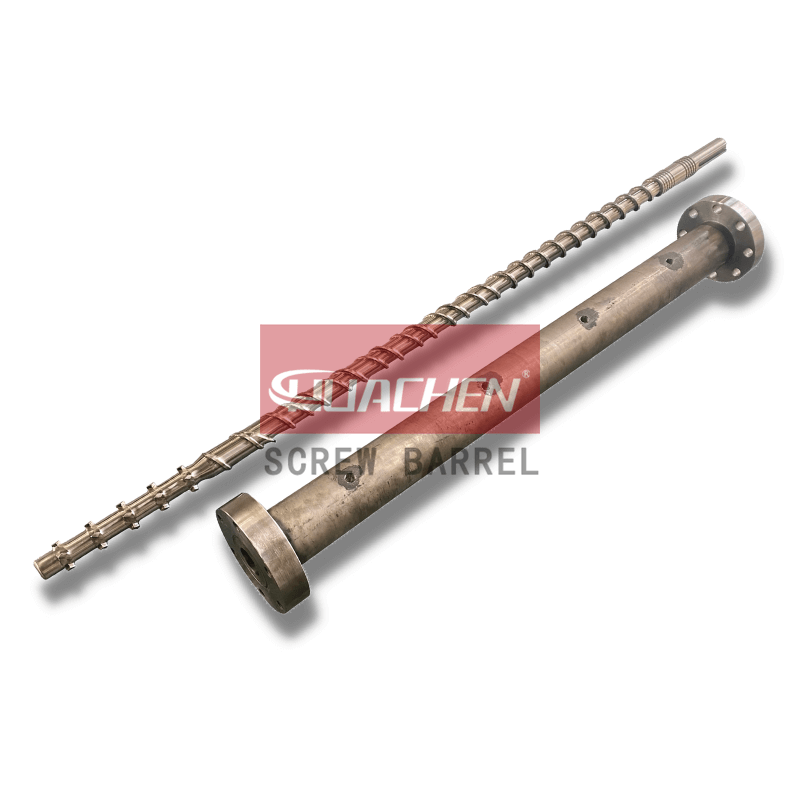

Co-extruder Screw And Barrel For PVC Marking Line Or Coating

● Components: 1 screw + 1 barrel + 1 flange

● Screw diameter: 25mm to 65mm

● Ratio of length: L/D=25 to 30

● Based material: Premium 38CrMoAlA, UNS K24065, SACM645, 41CrAlMo7-10, SKD61, nitralloy

● Surface hardness: HV≥1000

● Nitriding depth: ≥ 0.7mm

● Treatment available: Bimetallic barrel + bimetallic screw, nitriding barrel + bimetallic screw, nitriding barrel + nitriding screw

- Product Detail

Product name: Single Screw Co-extruder Screw And Barrel For Pipe Marking Line or Profile coating

Screw style: Conventional screw style, BM screw style, Maddock mixer screw

Components: 1 screw+ 1 barrel + 1 flange

Screw diameter: 25mm to 65mm

L/D ratio: L/D=25 to 30

Based material: Premium 38CrMoAlA, UNS K24065, SACM645, 41CrAlMo7-10, nitrialloy

Nitriding surface hardness: HV≥1000

Nitriding depth: ≥ 0.7mm

Treatment available: Bimetallic barrel + bimetallic screw, nitriding barrel + bimetallic screw, nitriding barrel + nitriding screw

Applications:

PVC or PE pipe marking line co-extruder, PVC profile coating co-extruder.

Single Screw Extruder Screw Barrel Model Specification:

| Model | Screw Diameter (mm) | L/D ratio | Screw speed Max. (rpm) | Motor required (KW) | Output (Kg/h) |

| HCS25 | Ф25 | 25 | 1-50 | 0.75/1.5 | 3-8 |

| HCS30 | Ф30 | 25/28 | 1-50 | 3 | 10 |

| HCS45 | Ф45 | 25/28/30 | 1-80 | 15/22 | 35-40 |

| HCS65 | Ф65 | 25/28 | 1-80 | 15/22 | 35-40 |

*Please check the actual screw barrel design with the salesperson before the order start.

Co-extruder Screw And Barrel Technical Parameter:

1. Material: Premium 38CrMoAlA, UNS K24065, SACM645, 41CrAlMo7-10, nitrialloy.

2. Plasma nitriding layer: 0.6-0.8mm

3. Nitriding time: more than 120 hours

4. Nitriding surface hardness: HV1000-1100

5. Nitrided Brittleness: Less than Grade1

6. Surface Roughness: Ra 0.4μm

7. Screw Linearity: ≤0.015mm

8. Alloy surface hardness: HRC≥61

9. Alloy deepness: 2-4mm

Single Screw Extrusion Screw Barrel Treatment Available:

1. Bimetallic barrel + bimetallic screw,

2. Nitrding barrel + bimetallic screw

3. Nitriding barrel + nitriding screw

Single Screw extruder Screw Barrel Common Used Related Parts:

1. Heaters and fans for screw barrel

2. Flange for screw barrel

3. Gearbox

Trading Term:

1. Business type: manufacture, foreign trade company.

2. Origin: Zhoushan City, Zhejiang, China

3. Warranty: 12 months for fresh material.

4. International commercial Terms: FOB, CFR, CIF, EXW

5. Screw and barrel Hs Code: 8477900000

6. Terms of payment: T/T, L/C

7. Average lead time: stork model in 7 days. Peak season lead time: 45 days, Off season lead time: 33 days

8. Transport package: AA Grade Wooden Case

Extrusion Barrel Screw Services:

1. Inspection of original single screw co-extruder screw and barrel, and other related barrel screw components.

2. Rebuilding Services to OEM specifications.

3. Modification services of screw designs to improve melting and mixing performance.

4. Emergency Service for an emergency turnaround service to minimize machine downtime.

MUST READ

1. Our extrusion barrel and screw are manufactured in strict accordance with standard drawings.

2. Before starting an order, please check the original screw barrel dimensions carefully, especially the assembly dimensions, to ensure that they can be installed and put into operation smoothly.

3. Screw barrel requires attention to assembly and maintenance, and incorrect assembly and maintenance can shorten the life of the screw barrel.