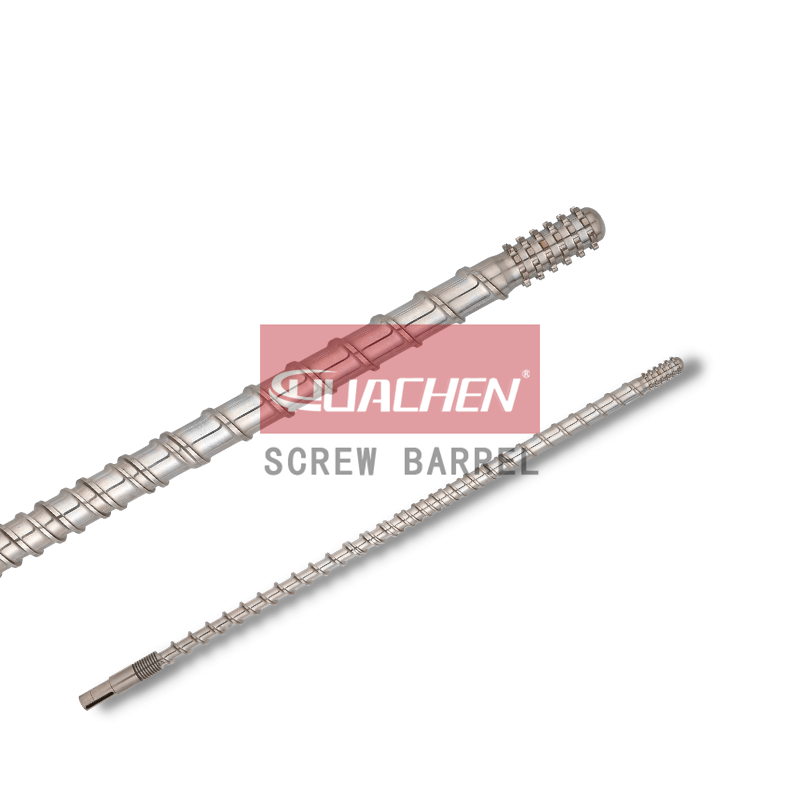

PE PP Nonwoven Fabric Extruder Screw And Barrel

● Components: 1 screw + 1 barrel + 1 flange

● Screw diameter: 45mm-200mm

● L/D ratio: 15-30

● Based material: Premium 38CrMoAlA

● Nitriding surface hardness: HV≥1000

● Nitriding depth: ≥ 0.7mm

● Treatment available: Bimetallic barrel + bimetallic screw, nitriding barrel + bimetallic screw, nitriding barrel + nitriding screw

- Product Detail

Product name: PE PP Nonwoven Fabric Extruder Screw And Barrel

Screw style: Barrier type screw, mixer screw head, PP spun bond nonwoven style screw, PP melt blown nonwoven style screw

Components: 1 screw+ 1 barrel + 1 flange

Screw diameter: 45mm to 200mm

L/D ratio: 15 to 30

Based material: Premium 38CrMoAlA, UNS K24065, SACM645, 41CrAlMo7-10, nitrialloy

Nitriding surface hardness: HV≥1000

Nitriding depth: ≥ 0.7mm

Treatment available: Bimetallic barrel + bimetallic screw, nitriding barrel + bimetallic screw, nitriding barrel + nitriding screw

Features:

Specially optimized nonwoven fabric application single screw extruder screw and barrel provided by HUACHEN screw barrel manufacturer. It helps to good plasticizing capacity for PE PP nonwoven fabric (spun bond nonwoven fabric and meltblow nonwoven fabric). Big factory strict standard quality provides stable service life.

Applications:

1. For spun bond nonwoven fabric.

PP spun bond nonwoven fabric, SMMS, hydrophilic SB fabric. Sanitary napkins wall stickers, tablecloths, bedsheets, bed covers, lining, adhesive lining, flakes, shaped cotton, various synthetic leather base fabrics, filter materials, HEPA filter, insulating materials, cement bags, geotextiles, covering fabrics, crop protection cloth, seedling raising cloth, irrigation cloth, thermal insulation curtain, space cotton, thermal insulation and sound insulation materials, linoleum, cigarette filter, tea bags

2. For melt-blown nonwoven fabric.

Surgical gowns, protective clothing, sterilization wraps, masks, diapers.

Screw Barrel Model Specification:

| Model | Screw Diameter (mm) | Screw L/D ratio | Screw speed Max. (rpm) | Motor required (KW) |

| HCS45 | Ф45 | 30 | 20-60 | 7.5 |

| HCS50 | Ф50 | 30 | 20-60 | 7.5 |

| HCS65 | Ф65 | 30 | 20-60 | 18.5 |

| HCS75 | Ф75 | 30 | 20-60 | 37 |

| HCS90 | Ф90 | 30/33 | 20-60 | 45 |

| HCS100 | Ф100 | 30 | 20-60 | 45 |

| HCS105 | Ф105 | 15 | 20-80 | 15/18.5/22/30 |

| HCS110 | Ф110 | 30 | 20-60 | 55 |

| HCS120 | Ф120 | 15/30 | 20-80 | 30 |

| HCS135 | Ф135 | 30 | 20-60 | 75 |

| HCS150 | Ф150 | 30 | 20-60 | 110 |

| HCS160 | Ф160 | 30 | 20-60 | 132 |

| HCS170 | Ф170 | 30 | 20-60 | 132 |

| HCS180 | Ф180 | 30 | 20-60 | 160 |

*Please check the actual screw barrel design with the salesperson before the order start.

Extrusion Screw Barrel Technical Parameter:

1. Material: Premium 38CrMoAlA, UNS K24065, SACM645, 41CrAlMo7-10, nitralloy.

2. Plasma nitriding layer: 0.6-0.8mm

3. Nitriding time: more than 120 hours

4. Surface hardness: HV1000-1100

5. Nitrided Brittleness: Less than Grade1

6. Surface Roughness: Ra 0.4μm

7. Screw Linearity: ≤0.015mm

8. Alloy surface hardness: HRC≥61

9. Alloy deepness: 2-4mm

Extrusion Screw Barrel Treatment Available:

1. Bimetallic barrel + bimetallic screw,

2. Nitrding barrel + bimetallic screw

3. Nitriding barrel + nitriding screw

Extrusion Single Screw Barrel Common Used Related Parts:

1. Heaters and fans for screw barrel

2. Flange for screw barrel

3. Gearbox

Trading Term:

1. Business type: manufacture, foreign trade company.

2. Origin: Zhoushan City, Zhejiang, China

3. Warranty: 12 months for fresh material.

4. International commercial terms: FOB, CFR, CIF, EXW

5. Screw and barrel HS code: 8477900000

6. Terms of payment: T/T, L/C

7. Average lead time: Peak season lead time: 45 days, Off season lead time: 33 days

8. Transport package: AA Grade Wooden Case

Single Screw Extruder Screw And Barrel Services:

1. Inspection of original extrusion screw barrel, and other related components.

2. Rebuilding Services to OEM specifications.

3. Modification services of screw designs to improve melting and mixing performance.

4. Emergency Service for an emergency turnaround service to minimize machine downtime.

MUST READ

1. As an expert screw barrel manufacturer, our screws and barrels are manufactured in strict accordance with standard drawings.

2. Before starting an order, please check the original screw barrel dimensions carefully, especially the assembly dimensions, to ensure that they can be installed and put into operation smoothly.

3. Screw barrel requires attention to assembly and maintenance, and incorrect assembly and maintenance can shorten the life of the screw barrel.