SKD Sleeve Fitted Barrel

● Min. Order (MOQ): 1 Set

● PVC, RPVC, UPVC, WPC, SPC

● Pipe, profile, sheet extrusion

● Compound pelletizing, recycling pelletizing

● HDPE Corrugated pipe extrusion

You Need Better SKD Sleeve Fitted Barrel at Good Price!

- Product Detail

HUACHEN Screw has been a leading SKD Sleeve Fitted Barrel manufacturer in Zhoushan Jintang since 2005. For rigid PVC extrusion machinery and product manufacturers, we have developed SKD sleeve fitted barrel technology since 2013. HUACHEN Screw offers a wide variety of services to its customers. We design, rebuild, modify, and upgrade screw barrels. Additionally, we have successfully exported screw barrels around the world.

>>Learn More About Our Company

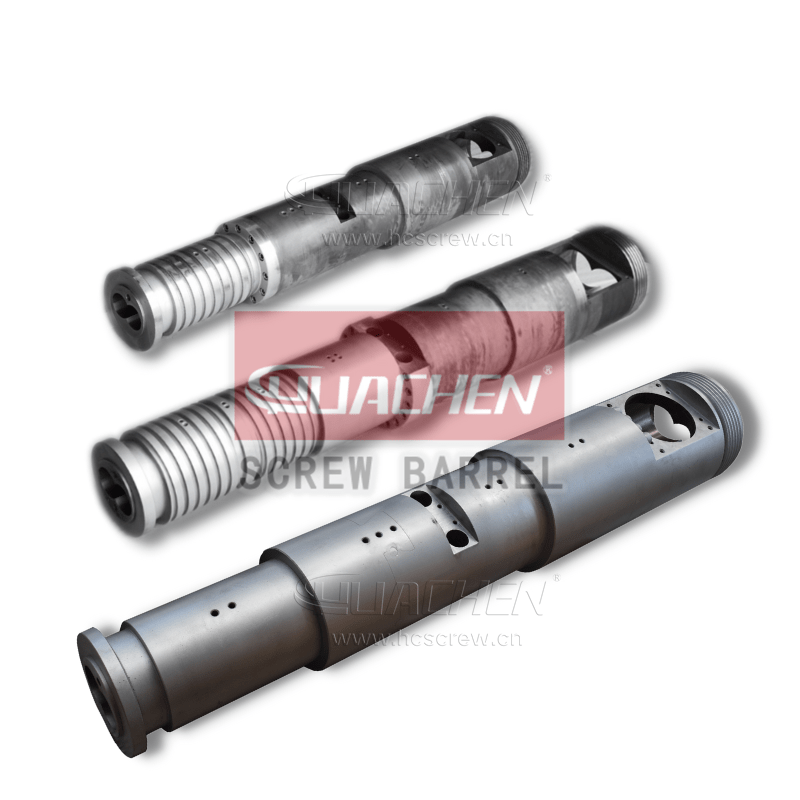

SKD Sleeve Fitted Barrel

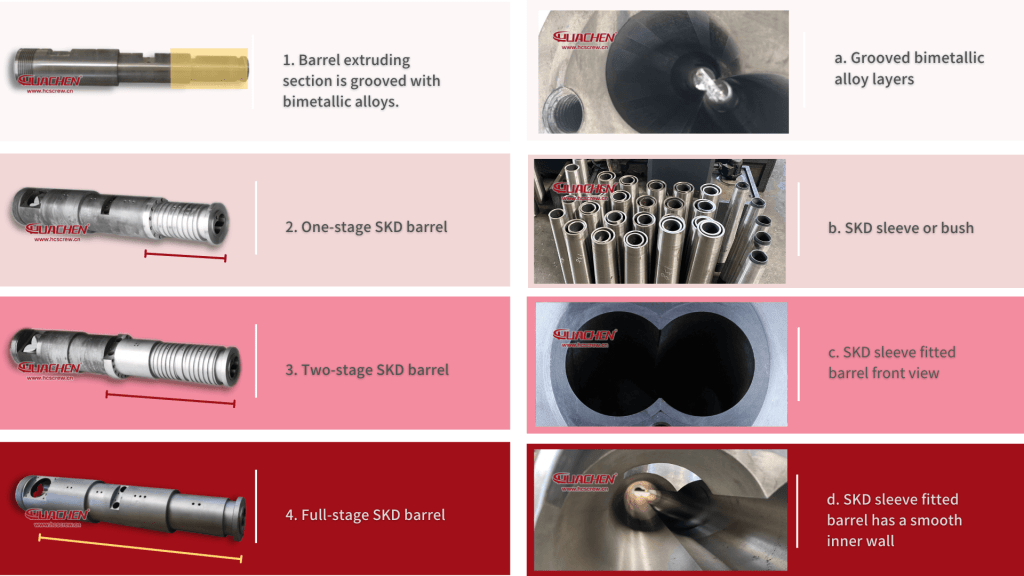

Conical screw barrels are divided into three sections depending on their functions: feed, melting, and extrusion. When using high-filled materials with more than 200 parts of filler, the wear-resistant solution for traditional bimetallic alloy barrels is particularly rapid in the extrusion section, which ultimately affects the quality and yield of the products produced.

Generally, the extrusion and melting sections of a conical screw barrel are the most wear-prone. We use a high wear-resistant material that is formed into a cone-shaped or cylindrical figure-of-eight bushing, which is inserted into the twin barrel’s inner wall. Due to this, the conical twin barrel is less prone to wear during use and is more suitable for extruding materials with high fill levels.

The SKD sleeve fitted barrel increases the service life by approximately 1.5 to 2 times when compared to a traditional bimetallic alloy barrel at a cost increase of 20%. Furthermore, the SKD sleeves are very stable and do not fall out easily.

High Wear Resistant SKD Sleeve

The base materials we use are SKD11 (upgraded D2) and SKD61, and the inner sleeves are made of upgraded wear resistant composite tungsten carbide alloy steel. They are selected based on the strength requirements of the material to be processed for the most suitable base material. Furthermore, HUACHEN Screw constantly develops new, highly wear-resistant base materials.

SKD sleeves or bush are available in thicknesses ranging from 6-10mm and have a surface hardness of around HRC 62. When processing high filled PVC products, we recommend SKD11 due to its hardness, toughness, and surface finish. At specific pressures, SKD11 wears minimally. As a result, conical twin barrels have a significantly longer service life at a more reasonable price. Contact us to receive an updated quote for SKD sleeve-fitted barrels.

>> Learn more about our SKD sleeve fitted barrel technology

Features

1. The SKD sleeve fitted barrel has good resistance to wear and corrosion, ensuring the quality of plastic products for a long time.

2. The disassembled barrel structure can be replaced with a new SKD sleeve when the inner sleeve wears or corrodes. There is a long service life for the barrel.

3. Three different lengths of SKD sleeve fitted barrels are available, depending on the PVC formulation and filling ratio.

We specialize in SKD sleeve fitted barrel

3. PVC, RPVC, UPVC, WPC, SPC, HDPE extrusion

4. Pipes, profiles, sheets, recycling pelleting extrusion

5. HDPE corrugated pipe manufacturing

6. Wood plastic composite, WPC door, window, flooring sheet manufacturing

7. Stone plastic composite, SPC sheet, flooring board manufacturing

The standard models of conical twin screw barrels for the above applications are in stock. To confirm the best price and delivery time, please contact us.

Specification

1. Based materials: Premium 38CrMoAlA (UNS K24065, SACM645, 41CrAlMo7-10)

2. Plasma nitriding surface hardness: HV 1000-1100

3. Plasma nitriding depth: ≥ 0.7 mm

4. Nitriding fragility: less than Grade I.

5. Surface Roughness: Ra 0.4 μm

6. Screw Linearity: ≤ 0.015mm

7. Alloy depth: 2-4 mm

8. Alloy surface hardness: ≥ HRC 61

9. barrel sleeve materials: SKD11, SKD61, tungsten carbide alloy steel

10. barrel sleeve surface hardness: ≥ HRC 62

11. barrel sleeve thickness: 6-10 mm

>>Learn more about our SKD sleeve fitted barrel parameters

We have a wide selection at good prices to help you get creative. The SKD sleeve fitted barrel is guaranteed to be of high quality. We are the China Origin Factory of SKD screw barrel. If you have any questions, please feel free to contact us.