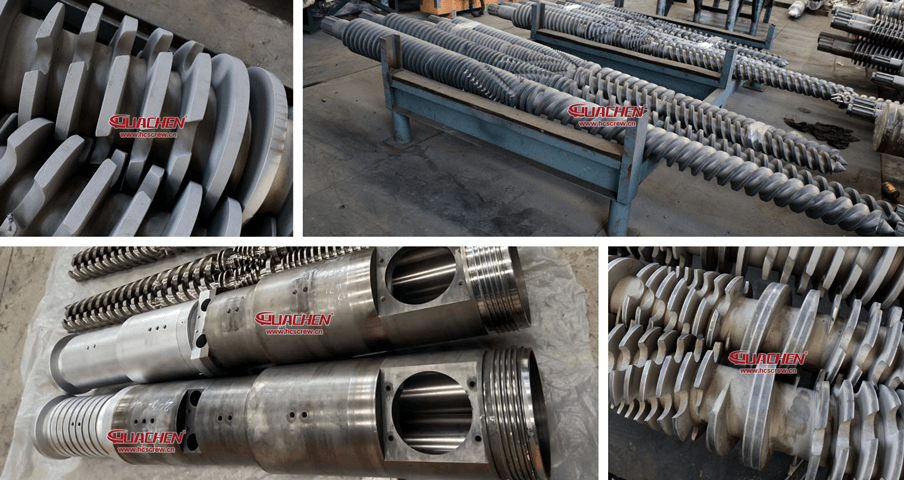

SPC Stone Plastic Composite Flooring Extruder Conical Twin Screw Barrel

● PVC, SPC, virgin or recycled materials

● Flooring sheets, flooring panels, flooring tiles, flooring trim

● Filler ratio of 200-300%, and greater than 300%.

● Min. Order (MOQ): 2 conical screws + 1 barrel

● Based material: Premium 38CrMoAlA tempered and nitrided, SKD11

● Anti-wear solution: SKD sleeve fitted barrel + bimetallic screw, bimetallic barrel + bimetallic screw, chrome coating screw, ceramic alloy screw

You Need Better Conical Twin Screw Barrel at Good Price!

- Product Detail

Maximize Your SPC Flooring Production with HUACHEN’s Conical Twin Screw Barrels

Enhance Your SPC Flooring Manufacturing with Cutting-Edge Technology!

Discover how HUACHEN’s innovative conical twin screw barrels can revolutionize your SPC stone plastic composite flooring extrusion process. Our advanced design offers superior performance, increased efficiency, and significant cost savings, making us the trusted choice for manufacturers across India, Pakistan, Bangladesh, the Middle East, Africa, and Southeast Asia.

Why Choose HUACHEN’s Conical Twin Screw Barrels?

- –Superior Performance: Specially designed to handle the high calcium powder fill ratio and poor material flow of SPC raw materials, ensuring complete plasticization and melting at low temperatures.

- –Enhanced Stability: Featuring a hydrodynamic design with an extended feed section and melting section, our screws provide stable feeding and extrusion, facilitating continuous and reliable production.

- –Durable Construction: Crafted from high-quality alloy steel 38CrMoAlA, with bimetallic alloy and electroplating hard chrome coatings on the screw flights for extended lifespan. The barrel includes a replaceable SKD sleeve for easy maintenance and reduced production costs.

- –Precision Engineering: CNC-machined screws and barrels guarantee consistent high performance, with smooth surfaces preventing material buildup.

Key Features

- –Specialized Design: Tailored to handle the high calcium powder fill ratio and poor material flow of SPC materials.

- –Stable Extrusion: Enhanced feed and stop sections based on flow dynamics for consistent extrusion and better feeding.

- –Durable Materials: High-quality alloy steel construction with bimetallic alloy processing and electroplating hard chrome coating for extended life.

- –Easy Installation: Standard models and designs for seamless integration into existing systems.

- –Extended Service Life: The bimetallic screw can have its service life extended by electroplating hard chrome on the screw’s small head section.

- Barrel with SKD Sleeves: Fitted barrels with different SKD sleeve lengths for customization.

Four Levels of Anti-Wear Solutions

- –Level 4: SKD sleeve fitted barrel and ceramic alloy coating screws for premium performance.

- –Level 3: SKD sleeve fitted barrel and hard chrome coating screws for enhanced durability.

- –Level 2: SKD sleeve fitted barrel and bimetallic screws for robust wear resistance.

- –Level 1: Bimetallic barrel and bimetallic screws for excellent efficiency and longevity.

Applications

- –SPC Stone Plastic Composite Flooring Sheet Extrusion

- –SPC Composite Flooring Panel Extrusion

- –SPC Flooring Tiles Extrusion

- –SPC Composite Profile Extrusion

- –PVC Composite Flooring Extrusion

Model Specifications

| Model | Speed (RPM) | Motor (KW) | Capacity (kg/h) | Screw length (mm) | Barrel length (mm) | Weight (kg) | Package dimension (m) |

|---|---|---|---|---|---|---|---|

| HCZS80/156 | 75 | 55 | 450 | 2116 | 1850 | 775 | 2.2*0.4*0.5 |

| HCZS92/188 | 34.7 | 110 | 750 | 2805 | 2520 | 1500 | 3.0*0.5*0.6 |

| HCZS 110/220 | 34.7 | 200 | 1250 | 3332 | 2995 | 2100 | 3.4*0.5*0.5 |

| HCZS115/225 | 34.7 | 300 |

Premium Materials

- 1. Core Materials: 38CrMoAlA, UNS K24065, SACM645, 41CrAlMo7-10, SKD11

- 2. Plasma Nitriding Layer: 0.7 mm

- 3. Nitriding Surface Hardness: ≥HV1000

- 4. Nitrided Screw Barrel Fragility: Less than Grade 1

- 5. Surface Roughness: Ra 0.4μm

- 6. Screw Linearity: ≤0.015 mm

- 7. Alloy Surface Hardness: HRC≥61

- 8. Alloy Depth: 4-6 mm

- 9. SKD Sleeve Surface Hardness: HRC≥62

- 10. SKD Sleeve Thickness: 6-10mm

For more detailed information, visit our screw barrel parameters page.

Fast and Reliable Delivery

- –Standard Models: Available within 7 days.

- –Peak Season Lead Time: Up to 45 days.

- –Off-Season Lead Time: Within 33 days, depending on part complexity.

How to Order from HUACHEN Screw Barrel

Upgrade your production with HUACHEN’s conical twin screw barrels. Follow our Step-by-Step Guide to Order from HUACHEN Screw Barrel.

For inquiries or more information about our SPC flooring extruder screw barrels, please contact us.

About HUACHEN Screw

Since 1993, HUACHEN Screw has been a leading manufacturer of conical twin screw barrels in Zhoushan Jintang. As members of the China Building Decoration and Resilient Flooring Association and directors of the China Jintang Plastic Screw Industry Association, we offer a wide range of services including custom designs and modifications. Our products are trusted worldwide for their durability and efficiency.