The Melting Temperature of PP and Process Methods

Date:2022-5-18 Author:hcscrew

Polypropylene (PP) is a cost-effective polymer with a unique set of physical, chemical, mechanical, thermal, and electrical qualities not found in any other thermoplastic.

PP Density 0.90-0.91 g/cm3

PP Melting Temperature 165 °C

Glass transition temperature -10 °C

Max/Min continuous Service temperature 100-110 °C/-20 To -10 ℃

PP Processing Temperature 190-300 °C

Polypropylene is available either as homopolymers or block co-polymers.

Homopolymers are high strength and stiff but become brittle at low temperatures.

Block co-polymers have ethylene blended-in to improve the low temperature performance but they have less clarity and gloss. The higher the ethylene content the softer and tougher the material becomes.

Random copolymers with lower ethylene content and a slightly different structure exhibit lower melting point, greater flexibility or enhanced clarity(transparency).

The properties of polypropylene can be altered by the addition of fillers like talc or glass fibres. Although talc increases stiffness, it also reduces impact strength and heat resistance with time. Glass fibres provide good rigidity, improved impact resistance, good resistance to creep and better environmental stress cracking resistance.

Strength

Low cost, processable in any way. Excellent aesthetic qualities, simple to manufacture. Low friction coefficient, stiffness, small weight, and strong tensile and flexural impact strength. Electrical insulation is excellent, and fatigue resistance is excellent. Excellent moisture resistance, Excellent strength. Autoclavable, extremely excellent chemical resistance, little moisture absorption. It is well suited to integrated hinges used for flip flop closures and compass boxes due to its natural flexibility.

Limitations

High thermal expansion, UV degradation, low weathering resistance, assault by chlorinated solvents and aromatics, difficult to bind or paint, easily oxidises, combustible.

Applications

From crates and bins to housewares, washing machine drums, and plumbing fittings, to automotive applications such as bumpers and dashboards, chemical and plating tanks, orthotics and prosthetics, PP film, containers, appliances, packaging, electrical/electronic, furniture, paint pails, industrial items, medical devices, and others.

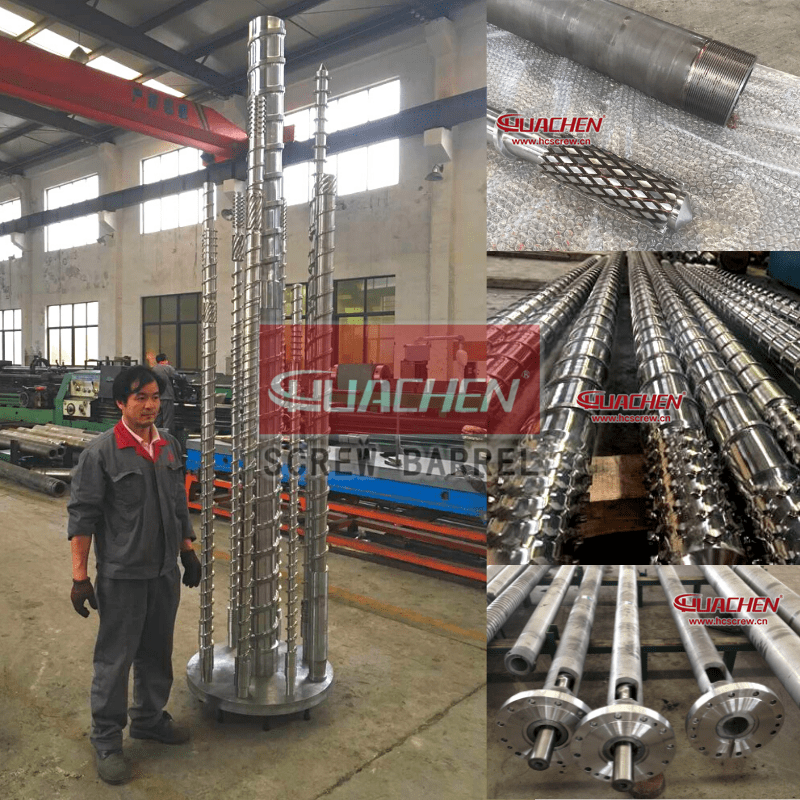

In conclusion, understanding the melting point of PP plastic can help us to design and optimize the extruder screw and barrel structure, as well as help extruder users reasonably choose a quality barrel screw.

YOU MAY ALSO LIKE

| Meltblown Nonwoven Fabric Screw Barrel ↗ Get details and price of PP meltblown nonwoven fabrics extruder screw barrel, upgraded screw barrel for finer fibre, softer meltblown fabrics… |

| Spunbond Nonwoven Fabric Screw Barrel ↗ Get details and prices for spunbond nonwoven fabric extruder screw barrel, upgraded screw barrel for finer fibre, softer spun bond nonwovens… |

| Nonwoven Fabric Machine Screw Barrel ↗ You need better nonwoven fabric machine screw barrel, find upgraded screw barrel for PP PE PET finer fibre, softer nonwoven at HUACHEN Screw… |

| Plastic Recycle Pellets Granulation Machine Screw Barrel ↗ Details and price of heavy duty plastic recycle pellets granulation machine screw barrel, find upgraded pelletizing screw barrel at HUACHEN… |

Contact HUACHEN Screw Barrel for more information about the melting points of PP plastics processed with extruder screws and to get a quote.

TAGS

HUACHEN Screw barrel recent post

- High-performance PVC Screw Barrel for Efficient Extrusion

- Durable Conical Twin Screw Barrel for Precision PVC Pipe Production

- High-Speed Screw Barrel for Increased Extrusion Efficiency

- Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders

- High-Precision Parallel Twin Screw Barrel for Extrusion Excellence

- Top Quality Single Screw Barrels for Plastic Extrusion Applications

- High-quality Extruder Screw Barrel for Reliable Performance

- Efficient Plastic Extrusion Screw Barrel for Superior Output

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;