Troubleshooting Vent Flow Material Problems in PVC Profile Formation with Conical Twin Screw Extruders

Date:2023-3-12 Author:hcscrew

Learn how to resolve vent flow material problems when forming PVC profiles with conical twin screw extruders. Our comprehensive guide provides practical solutions to ensure smooth and efficient extrusion processes.

When producing PVC profiles using a conical twin screw barrel, a common issue that may arise is vent flow problems. These occur when air and moisture are not properly expelled from the barrel during extrusion, leading to defects in the final product. In this blog, we will discuss the causes of vent flow material problems and provide solutions for fixing and preventing them.

Causes of Vent Flow Material Problems

1. Material Supply Issues If the conical twin screw extruder vents material while forming PVC profiles, it may be due to an imbalance between the material supplied and the material extruded. Excess material gets squeezed into the low-pressure vent, causing blockage and instability.

2. Temperature Control Improper temperature control can cause overplasticization, trapping volatile components and gas inside the material. This can lead to expansion and blockage at the vent holes.

Solutions to Vent Flow Material Problems

1. Adjust Material Supply and Temperature

- – Ensure the temperatures in the host material supply and compression areas are appropriate for proper plasticization.

- – Control the material density in the exhaust area to be 1.0-1.2g/ml.

- – Balance the feed screw speed and main screw speed to match extrusion and feed volumes.

2. Improve Temperature Management

- – Increase the temperature in the material supply and compression areas for better plasticization.

- – Ensure airtight channels for material flow around the venting holes.

3. Control Feed and Extrusion Speed

- – Reduce the speed of the feed or the extruder screw.

- – Increase processing aids like CPE impact modifiers to improve material plasticization.

4. Adjust Lubrication and Clearance

- – Modify the PVC profile formula to optimize the role of lubricants.

- – Adjust the axial clearance between the extruder screw and barrel to prevent leakage.

- – Reduce barrel temperature or adjust feeding and extrusion speeds to prevent over-plasticization.

Common Issues and Solutions

1. Powder Escape from Venting Holes

- – Caused by low temperature in the material supply and compression areas, and insufficient airtight channels.

- – Solution: Increase temperature and ensure channels are sealed.

2. Material Extrusion from Venting Holes and Increased Torque

- – Caused by rapid material addition, fast extrusion speed, and insufficient processing aids.

- – Solution: Slow down feed and screw speeds, and increase processing aids.

3. Dropping Extruder Torque

- – Caused by excessive lubricant, large axial clearance, and high temperatures leading to over-plasticization.

- – Solution: Adjust lubricant levels, re-adjust screw and barrel clearance, and manage temperatures.

Conclusion

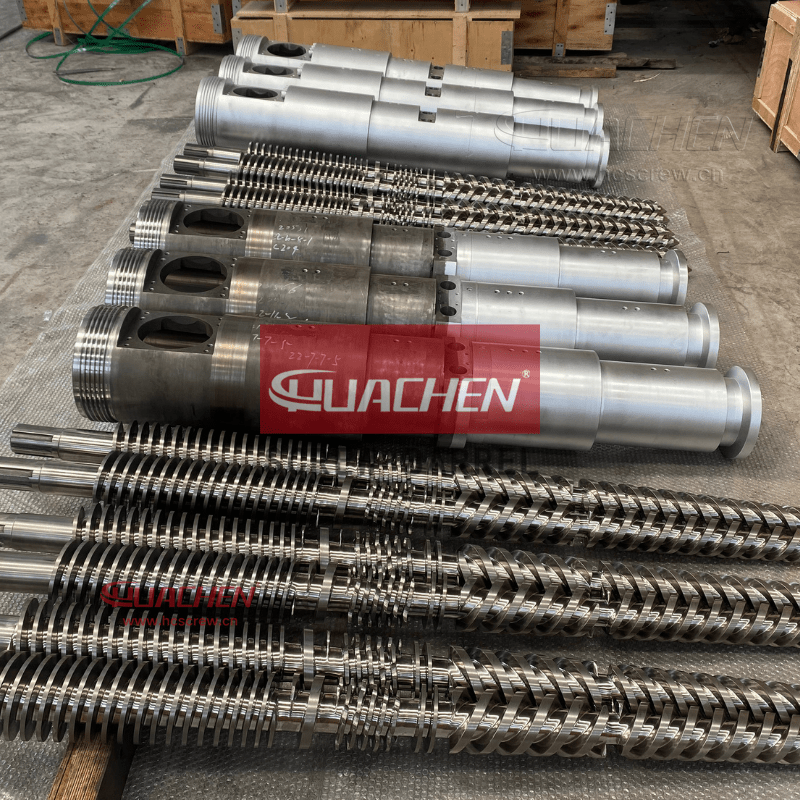

Vent flow problems are common when using conical twin screw barrels for PVC profile production. Evaluating the screw barrels and extrusion systems can reveal issues like poorly constructed screw flights and inadequate internal screw cooling systems. Addressing these root causes can prevent vent flow issues and ensure high-quality final products.

About HUACHEN

HUACHEN Screw has been a leading conical twin screw barrel manufacturer in Zhoushan Jintang since 1993. We specialize in designing and processing twin screw barrels, high-speed extruder screw barrels, and offer services including drawing rebuilding, design, modification, and customization. We have successfully supplied screw barrels to customers worldwide.

For more information about our products and services, visit HUACHEN Screw.

You May Also Like

| PVC Profiles Extrusion Screw Barrel ↗ Get details and quote for PVC profile extrusion screw barrel. We offer a wide variety of anti-wear screw barrels for many profile extrusions. |

| RPVC, CPVC, UPVC Screw Barrel ↗ Get details and latest price of RPVC, CPVC, UPVC PVC screw barrel, high-speed design, better anti-wear anti-corrosion screw barrel at HUACHEN. |

| 25 PVC Pipe And Other PVC Products Making Formulas ↗ Introduce 25 typical PVC product formulas in PVC extruding process. Such as PVC pipe, PVC panel production formula, PVC sheet, PVC profile. |

Tags

HUACHEN Screw Recent Post

- High-performance PVC Screw Barrel for Efficient Extrusion

- Durable Conical Twin Screw Barrel for Precision PVC Pipe Production

- High-Speed Screw Barrel for Increased Extrusion Efficiency

- Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders

- High-Precision Parallel Twin Screw Barrel for Extrusion Excellence

- Top Quality Single Screw Barrels for Plastic Extrusion Applications

- High-quality Extruder Screw Barrel for Reliable Performance

- Efficient Plastic Extrusion Screw Barrel for Superior Output

Tag Clound

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;