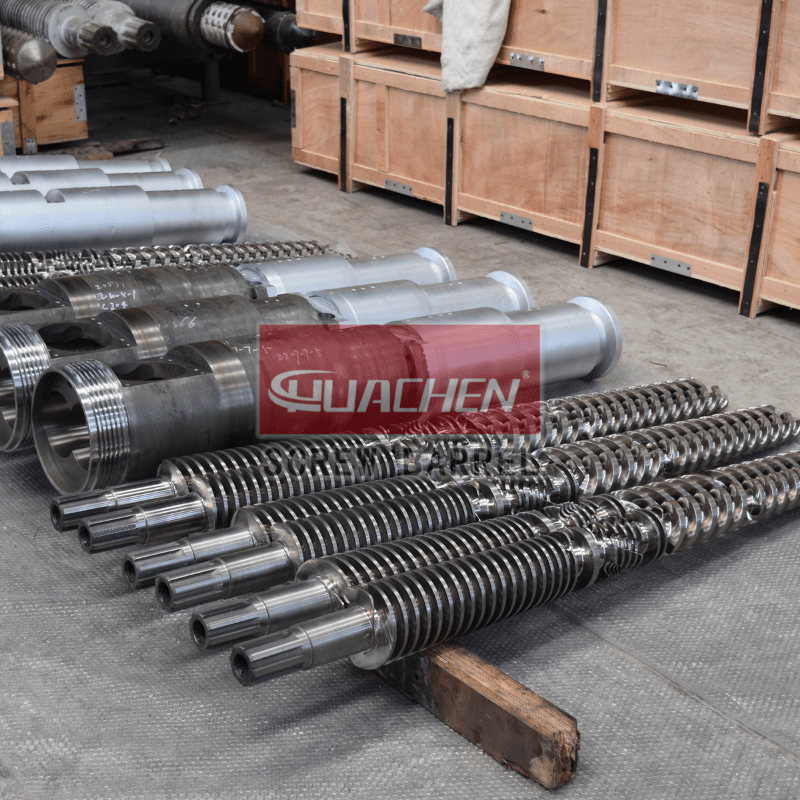

UPVC Window Frame and Door Extrusion Screw Barrel

● PVC / UPVC / WPC

● Filler ratio of 0-100, 100-200%, 200-300%, and greater than 300%.

● Min. Order (MOQ): 2 conical screws + 1 barrel

● Based material: Premium 38CrMoAlA tempered and nitrided, SKD11

● Anti-wear solution: SKD sleeve fitted barrel + bimetallic screw, bimetallic barrel + bimetallic screw, chrome coating screw, ceramic alloy screw

You Need Better UPVC window door Screw Barrel at Good Price!

- Product Detail

HUACHEN Screw has been an outstanding producer of UPVC window frame and door extrusion screw barrel in Zhoushan Jintang since 1993. As a leading manufacturer of plastic machinery replacement parts, HUACHEN Screw can provide its customers with a wide range of services. It involves rebuilding drawings as well as designing, customizing, and modifying them. Our company has also successfully exported and supplied screw barrels to customers worldwide.

>>Learn more about our company

What is UPVC window frame and door?

UPVC windows and doors have excellent thermal insulation and air tightness properties. It’s possible to make multi-cavity window and door frames with UPVC due to its heat transfer properties. UPVC profiles are trendy in the building materials market for windows and doors with better heat transfer properties than aluminium alloys.

UPVC Window Frame and Door Extrusion Screw Barrel

1. You can extrude PVC powder directly using a conical twin-screw barrel. Energy-efficient than pellet raw materials. It can also be extruded in two steps after pelletizing.

2. By using a low shear, high conveying design, the PVC window frame and door extruder screw provides stable extrusion pressure and efficient plasticizing and mixing results. We use CNC screw milling machines to make all our screws and barrels. It ensures high consistency between sets of screws and barrels. Screws and barrels are smooth and free of gaps so the melts won’t collect.

3. There are a lot of special screw designs we offer for different PVC formulations. Filling ratios of 50-100, 100-200%, 200-300%, and greater than 300% can be applied.

4. Screws and barrels use reliable corrosion- and wear-resistant materials. It makes the extrusion process more economical when dealing with abrasive materials like UPVC recycling and wood-plastic composites.

5. It has an easy-to-maintain oil-free closed temperature control system.

6. Excellent compatibility. We have both mainstream and high-efficiency conical twin-screw barrels for UPVC window and door profiles. All of them use standard assembly dimensions and are easy to install. For PVC window frames and door profiles, we have different barrel designs depending on the country and region. Please contact us to find out more about our specifications.

Manufactures of UPVC window frame and door extrusion screw barrel

| Model | Screw speed (rpm) | Motor (kW) | Capacity (kg/h) | Screw length (mm) | Barrel length (mm) | Weight (kg) | Package dimension (m) |

|---|---|---|---|---|---|---|---|

| HCZS51/105 | 34.7 | 22 | 80-120 | 1183 | 1070 | 196 | 1.3*0.3*0.4 |

| HCZS55/110 | 34.7 | 22 | 80-120 | 1430 | 1230 | 286 | 1.5*0.3*0.4 |

| HCZS65/132 | 34.7 | 37 | 150-250 | 1701 | 1480 | 410 | 1.8*0.3*0.4 |

| HCZS80/156 | 34.7 | 55 | 300-400 | 2116 | 1850 | 775 | 2.2*0.4*0.5 |

>> Please check the actual conical twin screw barrel design with the salesperson before the order starts.

Parameter

1. Material: Premium 38CrMoAlA, UNS K24065, SACM645, 41CrAlMo7-10, SKD11

2. Plasma nitriding layer: 0.6-0.8mm

3. Nitriding time: more than 120 hours

4. Nitriding surface hardness: HV1000-1100

5. Nitrided Brittleness: Less than Grade1

6. Surface Roughness: Ra 0.4μm

7. Screw Linearity: ≤0.015mm

8. Alloy surface hardness: HRC≥61

9. Alloy deepness: 4-6 mm

10. SKD sleeve surface hardness: HRC≥62

11. SKD sleeve thickness: 6-10mm

>> Learn more about our UPVC window frame and door extrusion screw barrel parameters

The ultimate solution for abrasion and wear

Level 4: SKD sleeve fitted barrel and ceramic alloy coating screws;

Level 3: SKD sleeve fitted barrel and hard chrome coating screws;

Level 2: SKD sleeve fitted barrel and bimetallic screws;

Level 1: bimetallic barrel and bimetallic screws.

Related UPVC window frame and door extrusion screw barrel spare parts

| Confluence core or adaptor | Big nut or barrel big neck | Barrel haf neck | Extruder machine frame |

| Striker plate | Couplings | Vacuum seat | Hopper |

| Extruder heaters | Blowers or fans | Extruder motor | Extruder gearbox |

>> Learn more about our twin extrusion spare parts available.

Trading Term

1. Business type: manufacturer, foreign trade company.

2. Origin: Zhoushan City, Zhejiang, China

3. Warranty: 12 months for fresh material.

4. International Commercial Terms: FOB, CFR, CIF, EXW

5. PVC screw barrel Hs Code: 8477900000

6. Terms of Payment: T/T, L/C

7. Average Lead Time: Ready stock model within 7 days, and custom-made model within 30 days depending on the complexity of the part.

8. Transport package: AA Grade Wooden Case

UPVC window frame and door extrusion screw barrel service

1. Examine the original UPVC window frame and door extrusion screw barrel and other associated spare parts.

2. Rebuilding services in accordance with OEM specifications. Provide a screw design suitable for UPVC window frame and door.

3. Screw design modification services to improve melting and mixing performance

4. Emergency Service for an emergency turnaround service to minimise machine downtime.

We have a wide selection at good prices to help you get creative. The UPVC window frame and door extrusion screw barrel for sale are guaranteed to be of high quality. We are the China Origin Factory of UPVC window frame and door extrusion screw barrels. If you have any questions, please feel free to contact us.