Vented Screw Barrel

● PP, PE, ABS, PS, PC, PMMA, and PVC

● PA6, PA66, PET

● Dry granulation of wet materials

● Recycling pelletizing extrusion

● Sheet extrusion

● MOQ: 1 screw + 1 barrel

You Need Better Vented Screw Barrel at Good Price!

- Product Detail

HUACHEN Screw has been a leading Vent Screw Barrel manufacturer in Zhoushan Jintang since 2005. HUACHEN Screw has many years of experience designing and manufacturing plastic machinery accessories, including custom screw barrels, rebuilding, modifying, and upgrading. In addition, our company exports and supplies screw barrels to customers around the world.

>>Learn More About Our Company

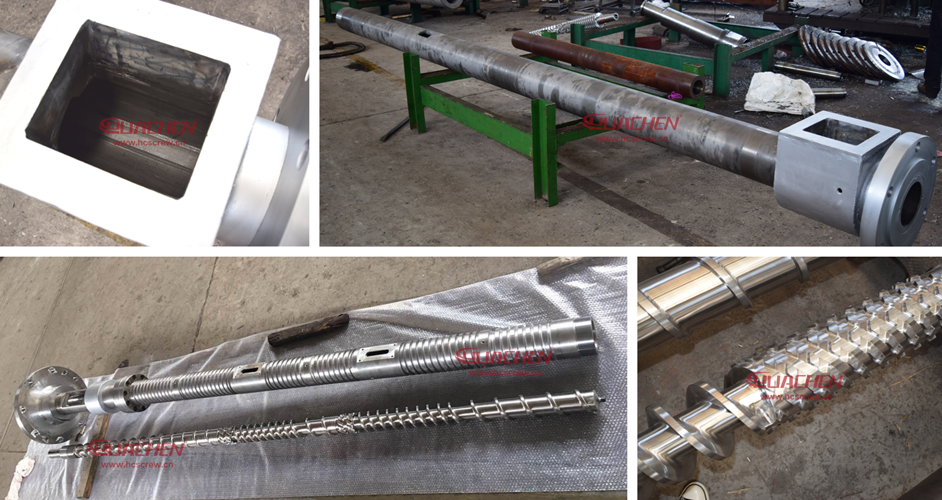

Vented Screw Barrel

As a key component of the venting extruder, the vented screw barrel is designed for venting gases (including air, water vapour, and volatile substances) from the raw material during the extrusion process. In this way, the plastic product is ensured high quality.

Compared to normal single screw barrels, vented screw barrels have venting holes in the middle and upper portion of the barrel. And there is a venting section in one of the screw sections. The vented screw barrel provides an effective solution to the problem of air bubbles and porosity in the extruded product caused by moisture absorption or volatile substances in the raw material.

Advantages of Vent Screw Barrel

1. Design optimized. HUACHEN offers highly efficient vented screw barrels with optimised screw mixing and shearing functions. This prevents material bubbling during use and blocked vent ports.

2. Accurate machining technology. With its venting properties and variable screw groove structure, this screw barrel features a particularly large L/D ratio. We use accurate barrel machining technology to enhance efficiency and reduce rejects during extrusion.

3. A high-quality corrosion-resistant solution. For the processing of recycled materials, we offer corrosion-resistant and wear-resistant solutions.

4. Good compatibility. To suit a wide range of vented extruders, we offer a variety of vented screw barrel models and designs. For more information on our specifications, please contact us.

Application of Vented Screw Barrel

1. Pelletizing rigid plastics, such as PP, PE, ABS, PS, PC, PMMA, and PVC.

2. Pelletizing of PA6, PA66 non-wovens, non-woven trimmings, PP non-wovens, and other soft plastics

3. Recycling of PE, PP, woven bags, etc.

4. Dry granulation of wet material after extrusion.

5. PET sheets, PC sheets, PP sheets, PE sheets, ABS sheets, etc.

Vented Screw Barrel Specifications

1. Single screw diameter available: 45mm to 200 mm

2. Single screw L/D ratio available: 24 to 43

3. Barrel max. length: ≤10000 mm

4. Barrel max. out diameter: ≤350 mm

5. Based materials: Premium 38CrMoAlA (UNS K24065, SACM645, 41CrAlMo7-10).

6. Plasma nitriding surface hardness: HV 1000-1100

7. Plasma nitriding depth: ≥ 0.7 mm

9. Nitriding fragility: less than Grade I.

11. Surface Roughness: Ra 0.4 μm

12. Screw Linearity: ≤ 0.015mm

13. Alloy depth: 2-4 mm

14. Alloy surface hardness: ≥ HRC 61

>>Learn more about our vented screw barrel parameters

Our vented screw barrel ultimate solution for abrasion and wear:

1. Alloy steel of high strength, tempered and nitride.

2. Overlay of nickel-based and molybdenum-based alloys on vulnerable screw parts with a thickness of 1 to 1.5 mm. Effectively provide 1.5 times longer service life.

3. hard chrome plating as option process.

4. bimetallic layer processing on barrel input opening section available.

5. Grooved feeding barrel structure available.

>>Learn more about our bimetallic screw barrel treatments

Production time:

Complete set of grooves feeding barrel within 30-38 days depending on the complexity of the part.

We have a wide selection at good prices to help you get creative. The vent extruder screw barrel for Sale is guaranteed to be of high quality. We are the China Origin Factory of vent screw barrel. If you have any questions, please feel free to contact us.