What Is HDPE Pipe? What is it used for?

Date:2022-6-17 Author:hcscrew

01 What is a polyethylene pipe?

A HDPE pipe is a plastic pipe made of polyethylene. It is possible to use PP-R, PE, and UPVC pipes all in urban construction. PE pipes are used in a wide range of applications, among which are water pipes and gas pipes. PE resin is made by polymerizing ethylene. Diverse polymerisation conditions such as pressure and temperature during polymerisation can result in different densities of resin. As a result, there is high density polyethylene, medium density polyethylene, and low density polyethylene.

When processing different types of PE pipes, the resin grade used depends on the application conditions as well as the extruder and mould requirements. In the international market, PE pipe material is grouped into 5 grades: PE32, PE40, PE63, PE80, and PE100. PE80 and PE100 are the most commonly used materials for gas and water pipes.

Common product categories of PE pipes

1) Polyethylene (PE) pipes for water supply

2) buried polyethylene pipes for gas.

3) HDPE silicon core pipes, the

4) HDPE cable sheathing pipes

5) HDPE pipes

6) PE buried cable sheathing pipes.

7) PE perforated pipes

8) HDPE double wall corrugated pipe

02 PE classification according to density

There are several different categories of PE based on their density and branching. Its mechanical properties are influenced by factors such as the degree and type of branching, crystal structure, and molecular weight. PE grades include high density polyethylene, linear low density polyethylene and low density polyethylene (LDPE).

Classification of PE in different densities

Ultra high molecular weight polyethylene (UHMWPE)

Ultra low molecular weight polyethylene (ULMWPE or PE-WAX)

High high molecular weight polyethylene (HMWPE)

High Density Polyethylene (HDPE)

High density cross-linked polyethylene (HDXLPE)

Cross-linked polyethylene (PEX cross-linked polyethylene)

Medium density polyethylene (MDPE)

Linear low density polyethylene (LLDPE)

Low density polyethylene (LDPE)

Very Low Density Polyethylene (VLDPE)

03 HDPE product characteristics

A thermoplastic polyolefin made from ethylene copolymer, high density polyethylene (HDPE) is a thermoplastic polyolefin. HDPE, introduced in 1956, has not yet reached its full maturity. Researchers are still working on finding new uses for it.

04 Key properties of HDPE pipe

HDPE grades differ based on a combination of four basic variables: density, molecular weight, molecular weight distribution, and additives. Different catalysts are used to create customised special performance polymers. The variables are combined to produce HDPE grades for various applications. Thus, achieving an optimum balance of properties.

05 HDPE pipe product properties

HDPE is a tasteless, odourless, odorless granule with a melting point of approximately 130°C and a relative density of 0.941 to 0.960. The material is heat and cold resistant, chemically stable, tough, and rigid. It also has good dielectric properties and resistance to environmental stresses.

06 HDPE pipe packaging, storage, and transportation

The warehouse area should be kept away from fires, protected from heat, dry and clean, forbidden to mix with impurities and kept out of the sun and rain. A clean, dry carriage or cabin with a roof is suitable for storing transportation, without sharp objects such as iron nails. Organic solvents such as flammable aromatic hydrocarbons and halogenated hydrocarbons must not be mixed.

07 HDPE pipe recycling

HDPE is the fastest growing segment in the plastics recycling market. It is easy to reprocess, has a minimal degradation rate, and is widely used in packaging. One of the main recycling methods is reprocessing 25% recycled material, such as post-consumer recyclables (PCR), with pure HDPE to produce food-safe bottles.

08 Applications of HDPE pipes

1. HDPE gas pipes

(1) Reliable connection: HDPE pipes are connected to each other via electrothermal fusion, so the joint is stronger than the pipe body itself.

(2) Good low temperature impact resistance: the low temperature embrittlement temperature of PE is extremely low and can be used safely in the temperature range of -60-60°C. During winter construction, no brittle cracking of the pipe will occur due to the good impact resistance of the material.

(3) Good stress cracking resistance: HDPE has low notch sensitivity, high shear strength and excellent scratch resistance, and outstanding resistance to environmental stress cracking.

(4) Good chemical resistance: HDPE pipes are resistant to a wide range of chemical media, and the chemicals present in the soil do not cause any degradation effect on the pipes. Polyethylene is an electrical insulator, so no rot, rust or electrochemical corrosion will occur; in addition it will not promote the growth of algae, bacteria or fungi.

(5) Ageing resistance and long life: In open air, carbon black incorporated into polyethylene pipes can be stored or used for 50 years without deterioration from UV rays.

(6) Good abrasion resistance: comparative tests of the abrasion resistance of HDPE pipes and steel pipes show that HDPE pipes are four times more abrasion resistant than steel pipes. In the field of slurry transport, HDPE pipes have better wear resistance compared to steel pipes, which means that HDPE pipes have a longer service life and better economy.

(7) Good flexibility: Flexible HDPE pipe can be bent and can be easily bypassed obstacles by changing its direction. The flexibility of HDPE pipe can also reduce the number of fittings needed and the cost of installation.

(8) Ease of handling: Compared to concrete, galvanised and steel pipes, HDPE pipes are lighter, making them easier to handle and install, and lower labour and equipment requirements result in lower installation costs.

(9) A variety of new construction methods: In addition to the traditional excavation method for construction of HDPE pipes, there are other non-excavation methods such as pipe jacking, directional drilling, pipe lining, pipe cracking and other types of construction, which are the only options for places where excavation is not permitted, so HDPE pipes are more widely used.

2. PE water supply pipes

PE pipes for water supply are an alternative to traditional steel pipes and polyvinyl chloride (PVC) drinking water pipes.

(1) Long service life: under normal conditions, the minimum service life is 50 years.

(2) Good hygiene: PE pipe is non-toxic, does not contain heavy metal additives, does not scale, does not breed bacteria, and solves the problem of secondary pollution of drinking water very well. It conforms to the provisions of GB/T17219 safety evaluation standard and the relevant health and safety evaluation provisions of the State Ministry of Health.

(3) It is resistant to the corrosion of various chemical media: no electrochemical corrosion.

(4) Smooth inner wall, low coefficient of friction, allowing medium to pass through easily and resisting wear well.

(5) Good flexibility, high impact strength, resistance to strong shock and distortion.

(6) Light weight, easy to transport and install.

(7) Unique electric fusion connection and hot fusion butt joint, hot fusion socket connection technology makes the interface strength high and the pipe body, to ensure the safety and reliability of the interface.

(8) Simple welding process, convenient construction and low comprehensive project cost.

(9) PE environmental health water supply pipe material dn20 ~ dn90 for blue, dn110 above blue or black with blue line, other colours need to be customized, the colour of accessories and pipe colour corresponds to.

(10) Low resistance to water flow: HDPE pipes have a smooth inner surface with a Manning coefficient of 0.009. The smooth performance and non-adhesive characteristics ensure that HDPE pipes have a higher conveying capacity than traditional pipes, and also reduce the pressure loss and energy consumption of water transmission in pipelines.

3. PE Sewerage Pipe

Polyethylene drainage pipes are also known as high density polyethylene pipes. Municipalities prefer this type of pipe for many projects. Sewage systems are its main application. The materials’ wear resistance, acid and corrosion resistance, high temperature resistance, and strong pressure resistance have allowed them to gradually replace traditional pipes on the market. This is, especially due to their light weight, ease of installation, and movement, and they are the first choice for new materials.

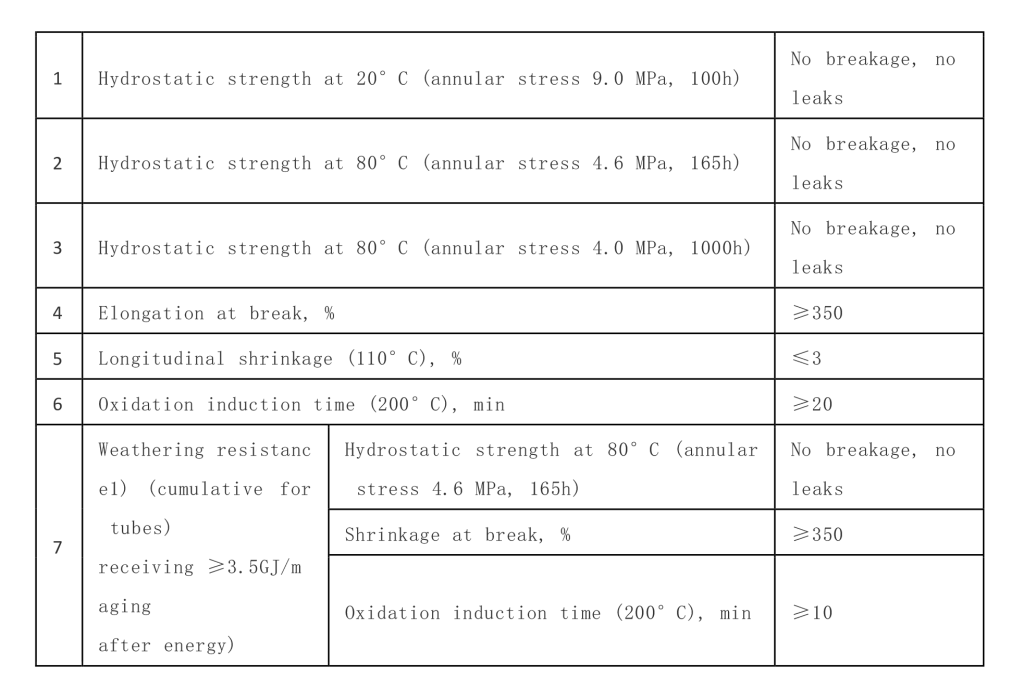

09 PE pipe performance

Summary

The above are basic introductions to PE pipe and HDPE pipe. Understanding these plastic pipe materials will allow us to optimize our HDPE screw barrel and extruders. If you need more information about HDPE pipe production, please contact HUACHEN Screw Barrel Factory for technical support.

TAGS

HUACHEN Screw Barrel Recent Post

- High-performance PVC Screw Barrel for Efficient Extrusion

- Durable Conical Twin Screw Barrel for Precision PVC Pipe Production

- High-Speed Screw Barrel for Increased Extrusion Efficiency

- Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders

- High-Precision Parallel Twin Screw Barrel for Extrusion Excellence

- Top Quality Single Screw Barrels for Plastic Extrusion Applications

- High-quality Extruder Screw Barrel for Reliable Performance

- Efficient Plastic Extrusion Screw Barrel for Superior Output

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;