What Is PE Double Wall Corrugated Pipe?

Date:2022-5-29 Author:hcscrew

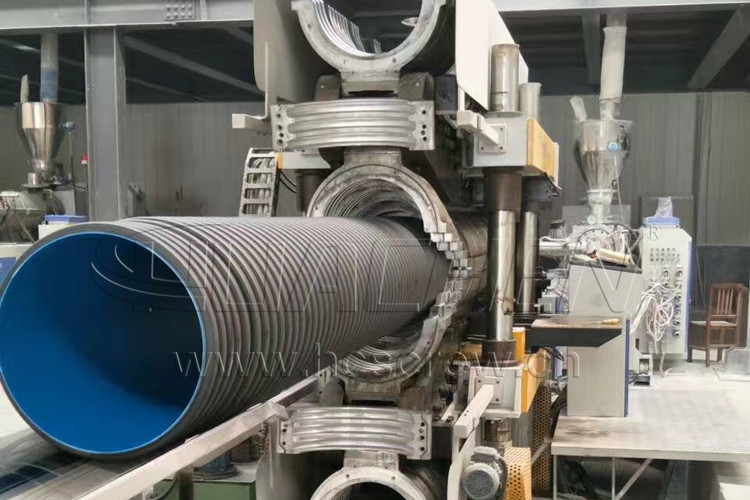

1. Definition of PE double wall corrugated pipe

PE double-walled corrugated pipes have a smooth outer surface, with trapezoidal or curved corrugated ribs on the outer surface and hollow corrugations on the inner and outer surfaces. These pipes are produced using extrusion technology to minimize raw material consumption while maintaining ring stiffness. It is known as PE double-wall corrugated pipe due to the fact that its main raw material is polyethylene (PE).

2. The advantages of PE double-wall corrugated pipe

① save raw materials, with the same raw materials to make the same outside diameter of the pipe, corrugated pipe can save more than 30% of the raw materials than the solid wall pipe.

② Light weight. The specific gravity is less than 50% of cast iron and cement pipes.

③ Easy installation. Fast construction progress, compared with traditional cement pipe, the use of PE corrugated pipe can improve the installation progress by more than 3 times.

④ PE double-wall corrugated pipe adopts flexible connection with good sealing performance.

⑤ Low production cost and superior comprehensive economic performance.

3. Applications of PE double-wall corrugated pipe

① Municipal engineering, used for underground drainage pipes, sewage pipes, water pipes, ventilation pipes, etc. of buildings.

②Electrical and telecommunication engineering, as the protection pipe of electric power cable, optical cable and communication signal cable.

③Industrial, as polyethylene material has excellent resistance to acid, alkali and corrosion, structural wall pipe can be used for water supply and drainage pipes in chemical, pharmaceutical, environmental protection and other industries.

④For agriculture and garden engineering, it can be used to drain and irrigate farmland, orchards, tea gardens, and forests. It can also be used for rural irrigation, saving 70% of water and 13.9% of electricity.

⑤ Road projects, used as seepage and drainage pipes for railways, highways, golf courses, football fields, etc.

⑥Mine, used as ventilation, air supply pipe and drainage pipe of mine.

4. Product performance

The three main performance indicators of corrugated pipes are ring stiffness, impact resistance and ring flexibility.

(1) Ring stiffness

Ring stiffness represents the ability of the pipe to resist external pressure in kN/m2. The larger the value of ring stiffness, the stronger the pipe’s ability to resist external pressure, and the thicker the corresponding wall thickness of the pipe.

2) Impact resistance

Using the method of drop hammer impact, the true impact rate (TIR) is ≤10% in a 0±1°C environment (which can be interpreted as 10 allowed to break 1, but is not exactly equivalent). The factors affecting impact resistance are similar to those affecting ring stiffness.

3) Ring flexibility

In ring flexibility testing, the compression is greater than in ring stiffness testing. Normally, the specimen is unloaded when the change in diameter in the vertical direction reaches 30% of the original diameter. Once the specimen has been unloaded, it is observed to determine if the inner wall remains round and smooth, if there is reverse bending, if there is rupture, and if the two walls have separated. The flexibility of the ring indicates the pipe’s resistance to deformation.

As well as ring stiffness, ring flexibility, and impact resistance, the national standard includes requirements for creep ratios (reflecting the creep of the corrugated pipe under load, which affects the service life of the product) and oven tests (indicating the degree of bonding between inner and outer walls of the corrugated pipe, as well as the structural stability of the structure).

5. PE double wall corrugated pipe raw materials

1. PE double-walled corrugated pipe raw materials are usually composed of polyethylene, enhanced functional masterbatch and pigments, etc. If the raw material is wet, a defoamer can be added to improve production efficiency.

2. Requirements for raw material performance: How to produce a low-cost, high-quality corrugated pipe depends largely on the choice of raw materials and the matching of formulations.

1) In general, melt flow rate (MFR), oxidation induction time (OIT) and density are required for polyethylene (PE) properties. Melt flow rate reflects molecular weight. Accordingly, a higher melting rate is beneficial to the material processing and moulding. However, it should not be too large, too large on the ring stiffness of the impact will be chosen between 0.8 and 1.5g/10min (190 °C, 5kg). Oxidation damage occurs when oxidation induction occurs. Corrugated pipes require 50 years of service, so controlling the oxidation induction time of the raw material is crucial. Raw material for corrugated pipes should be oxidized for 20 minutes at 200°C. Changing the density of polyethylene can alter its performance for medium and high density polyethylene.

2) Choosing a functional masterbatch is also crucial. Functional masterbatch for drainage pipes has no national standard, and the performance of the products from different manufacturers is not consistent. To select a functional masterbatch, it is important to take into consideration its dispersibility, coupling and degree of modification of the polyethylene.

3) The quality of the product is also determined by the formulation. In order to reduce costs, some manufacturers increase the number of functional masterbatch without restriction, but this does not guarantee product quality and compromises long-term development and core competitiveness. Below is an example of a reasonable formula.

| Name | Proportion | Remarks |

| Polyethylene | 80% – 85% | Clean recycled material can be added in moderation |

| Functional masterbastch | 15% -20% | Should not exceed 20% maximum |

| Pigments | 2% – (±0.5) | —— |

Summary

The above information provides a general overview of PE double wall corrugated pipes. For further information, please visit our official website or contact us. HUACHEN Screw Barrel, a leading manufacturer of screw barrel for PE double wall corrugated pipe extruders. We will continue to update this website with more information on extrusion and production of PE double wall corrugated pipe.

TAGS

HUACHEN Screw barrel recent post

- High-performance PVC Screw Barrel for Efficient Extrusion

- Durable Conical Twin Screw Barrel for Precision PVC Pipe Production

- High-Speed Screw Barrel for Increased Extrusion Efficiency

- Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders

- High-Precision Parallel Twin Screw Barrel for Extrusion Excellence

- Top Quality Single Screw Barrels for Plastic Extrusion Applications

- High-quality Extruder Screw Barrel for Reliable Performance

- Efficient Plastic Extrusion Screw Barrel for Superior Output

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;