What Is Plastic Cast Film And How Is It Produced?

Date:2022-11-02 Author:hcscrew

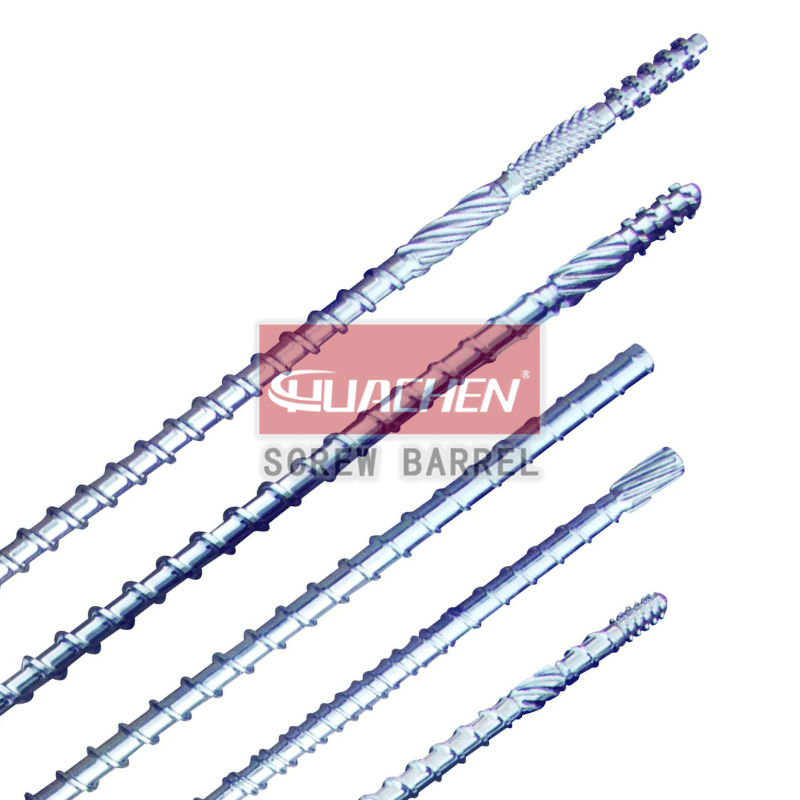

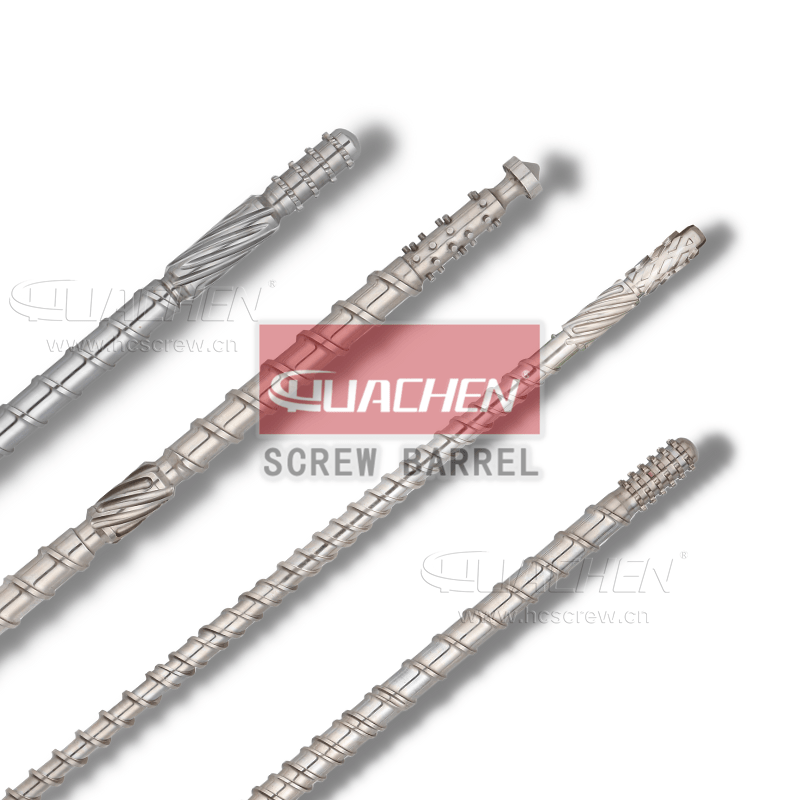

Plastic films’ performance isn’t just affected by the plastic particles used, but also by the production process and process parameters. Film, for example, can be made in different ways. Despite the same material and production process, temperature, pressure, blowing ratio, and other factors can affect the end result. HUACHEN Screw, a professional manufacturer of high strength plastic film making screw barrels, briefly introduces what cast film is, as well as cast film features and production processes.

01 Cast films

Cast film is made by casting, with C as the prefix, like cast polypropylene, called CPP. Cast films come in extruded and solvent forms.

a. Solvent cast film method

Solvent casting makes films thinner and more uniform. You won’t find it in packages. Because it’s expensive, toxic, and you have to use a lot of solvents, which makes it expensive to run. There are only a few films that can’t be extruded, like cellophane, that are manufactured with solvents.

The solvent-based cast film process involves coating a solution of thermoplastic or a prepolymer of thermoset plastic with a peelable carrier, drying it in a drying oven, melting and plasticizing it into a film layer that cools down, peels off the carrier release surface, and rolls into a film. It could be steel tape, silicone rubber coated release paper or rolls. It’s possible to make thin, flat films by casting the solution over a heated mercury pool. After the solvent evaporates, remove the film from the mercury surface and roll it up.

b. Solvent cast films features.

(1) Films can be very thin, usually 5 to 8 um, and molecular films, which use mercury as a carrier, can be as thin as 3 um.

(2) This film has high transparency and low internal stress, which makes it ideal for applications requiring high optical performance, like film reels and safety glass interlayers.

(3) Good film quality, uniform thickness, and does not mix with impurities.

(4) Solvent cast film doesn’t fully plasticize and extrude, has a large intermolecular distance, and has a weak structure.

(5) High production costs, high energy consumption, high solvent usage, and slow production.

Using the solvent cast method, you can make cellulose triacetate, polyvinyl alcohol and chlorine vinegar resins. Additionally, PTFE and PC are also commonly applied in solvent calendering to produce films. Heat-resistant films are usually made of heat-resistant plastics.

02 Extrusion cast film

a. Extrusion cast film method

Let’s take the production process of CPP extrusion cast film as an example, using cold grade copolymer polypropylene CPP particles as the raw material, MFR 6~9g/10min.

Extruder extrusion → T-shaped mouth die cast – air knife → 1# cooling roll → 2 cooling roll → corona treatment → cutting waste edge → Winding.

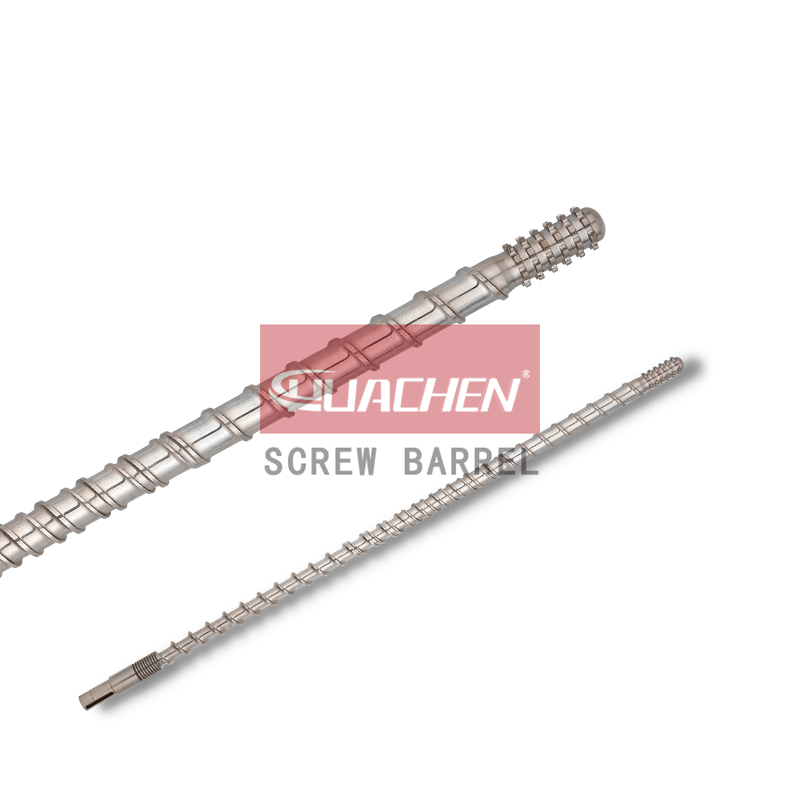

The extruder screw has a diameter of 65mm, L/D=32, normal progressive screw.

The barrel temperature: 210°C, 230°C, 240°C, 255°C, 265°C in 5 sections. Connector temperature 265°C, resin temperature 230~237°C, T-mouth die temperature (2m wide in total) are 265°C. 1# cooling rolls use tap water to cool to 0*-5°C via a cooler heat exchanger; 2# cooler cooling water is 8~10°C. T-mouth die uses bolts. Manually adjust the thickness of the cast film.

Air knives and air gaps play a big role in cast film extrusion. Basically, an air knife is a narrow slit underneath the T-mouth die, which lets compressed air eject, so the molten film can stick to the 1# cooling roller. It makes the plastic film flatter and reduces necking at the two ends by cooling it better and making the surface flatter.

There is an air gap between the surface of the 1# cooling roller and the molten plastic film leaving the T-mouth mould. At high temperatures, the longer the film is in contact with air, the wider the air gap. It’ll increase surface vaporization. As the air gap gets wider, the necking phenomenon gets severe, the flatness gets more noticeable. A smaller air gap makes it more difficult to control the appropriate air gap distance, which is about 2.0 cm. It improves heat sealing, but not adhesion, because there’s less air gap.

b. CPP film performance.

Thickness: 20-30 um

Haze: 5.5-6%

Tensile strength, longitudinal/horizontal: ≧ 40 / 20 MPa

Elongation at break, longitudinal/horizontal: ≧ 400% / 500%

Right-angle tear strength, longitudinal/horizontal: ≧ 100 kgf/cm / 140 kgf/cm

Surface tension: ≧ 42×10-3 N/m

c. Cast extruded film features

1) Production speed can be greater than blowing technology, up to 60 ~ 80m / min. The extrusion cast film production line of some brand plastic film machines can be as high as 150 * 200m / min. However, the blowing method can only reach 30 * 60m / min due to the limitations of the cooling speed of the bubble film.

(2) Extrusion casting produces a better transparent film than blown film, and both PE and PP can be made with high transparency by extrusion casting. PP cannot be transparent when it is blown moulding. To get high transparency, you need water cooling.

(3) Extrusion cast film has better uniformity than blow-molded cast film.

(4) Extruded cast films have balanced longitudinal and transverse properties, whereas blown films have different longitudinal and transverse properties due to traction roller speed and blowing ratio. By extrusion casting, the film is transferred from one roller to another. The extruded film shouldn’t be stretched vertically or horizontally, so there shouldn’t be any winding or traction pull.

(5) Extruded cast film doesn’t stretch in any direction, so it has better heat seal than blown film, while biaxially oriented film doesn’t. Cast film shrinks minimally when heated, so it’s good for heat sealing plastic bags.

Summary

These are the characteristics and production methods of plastic film cast film. Our company manufactures cast film screw barrels for plastic films. Please contact us if you would like the latest designs and quotes on cast film screw barrels.

YOU MAY ALSO LIKE

| Cast PE Film CPE Film Making Extrusion Screw Barrel↗ Get details & quote for cast PE film CPE film making extrusion screw barrel. Good quality screw barrels cast film making at HUACHEN factory… |

| Plastic Film PP Film Extrusion Screw Barrel ↗ Get details & prices for plastic film PP film extrusion screw barrel. Better anti-wear screw barrels for plastic film making at HUACHEN… |

| Blown Film Extruder Screw Barrel ↗ Get details & quote for blown film extruder screw barrel. Bimetallic alloy anti-wear screw barrels for better plastic film making at HUACHEN… |

RELATED CONTENT ABOUT SCREW BARREL

- High-performance PVC Screw Barrel for Efficient Extrusion

- Durable Conical Twin Screw Barrel for Precision PVC Pipe Production

- High-Speed Screw Barrel for Increased Extrusion Efficiency

- Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders

- High-Precision Parallel Twin Screw Barrel for Extrusion Excellence

- Top Quality Single Screw Barrels for Plastic Extrusion Applications

- High-quality Extruder Screw Barrel for Reliable Performance

- Efficient Plastic Extrusion Screw Barrel for Superior Output

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;