What is Polyamide 46 or Nylon 46?

Date:2022-6-01 Author:hcscrew

What is PA 46?

Polyamide 46 (Nylon 46) is the highest melting point of any commercial polyamide, being a semi-crystalline aliphatic polyamide with the highest amide group density. This material also has a very high crystallinity (70%) which keeps the Young’s Modulus very high up to melting temperatures. Due to this, PA 4.6 is ideal in applications where components encounter (occasionally) high temperatures, such as in automotive parts near the engine or in electronics, where (lead-free) soldering requires high temperature resistance.

PA 46 Density 1.18 g/cm3

Glass Transition Temperature (Tg) 78 ℃

PA 46 melting point Tm 295 ℃

Processed by extrusion and injection moulding methods

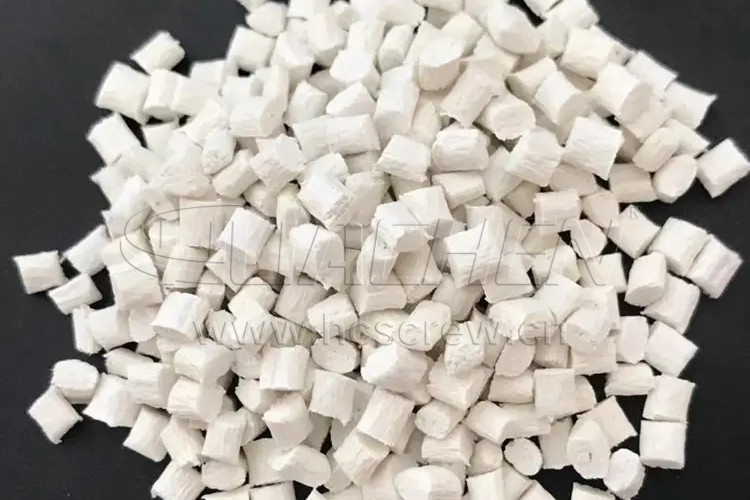

PA 46 has a white, opaque surface with a glossy finish, high stiffness and strength when dry, but a great deal less when moistened. At higher temperatures, there is little difference between dry and conditioned, showing the lowest coefficient of friction, as well as the highest level of toughness and wear resistance. Its HDT at 1.8MPA is 160 ℃, and 285 ℃ when filled with 30% of glass fibers.

PA 46 has superior mechanical resistance and fatigue resistance compared to that of PA 66.

Strength

PA 46 is commonly used as a replacement for metal in high temperature applications. It has excellent tribological properties, is very fluid, so is suitable for parts with complex shapes and thin walls, and can be manufactured in a very short cycle time frame.

Limitations

PA 46 has high water absorption, less resistant to strong acids and bases, drying before processing required.

Applications

They can make (miniature) connectors, sockets for memory modules and processors, LEDs, miniature printed circuit boards, electronic and automotive components such as turbocharger inlets/intercoolers, gears, industrial transmission components, sensor encapsulation, films, belt fibers, and aerospace turbine engine components.

By understanding the melting point of PA 66, we can optimize the screw barrel structure of a PA extruder. It also helps to select the right screw barrel.

Contact HUACHEN Screw Barrel for a quote, or to speak to our expert team about the melting points of PA46 processed by extruder screws.

TAGS

HUACHEN Screw barrel recent post

- High-performance PVC Screw Barrel for Efficient Extrusion

- Durable Conical Twin Screw Barrel for Precision PVC Pipe Production

- High-Speed Screw Barrel for Increased Extrusion Efficiency

- Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders

- High-Precision Parallel Twin Screw Barrel for Extrusion Excellence

- Top Quality Single Screw Barrels for Plastic Extrusion Applications

- High-quality Extruder Screw Barrel for Reliable Performance

- Efficient Plastic Extrusion Screw Barrel for Superior Output

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;