What You Need To Know When Customized Screw Barrel For Your Plastic Blown Film Extruder

Date:2022-10-28 Author:hcscrew

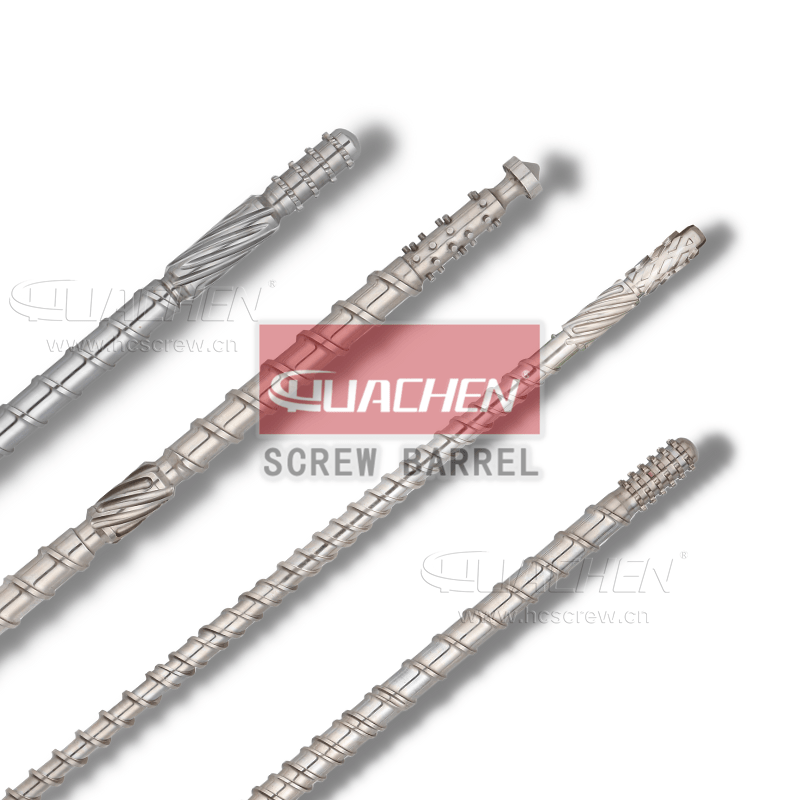

Blown film screw barrels are the heart of blown film extruders. You can replace it when it wears out. It’s time to change your blown film extruder screw and barrel when your output drops, or the quality of your product drops. Generally, blown film screw barrels last a long time. So users of plastic blown film extruders often customize new screws with the latest designs and upgraded quality. Now how do you choose the right screw barrel for your extruder? We’ll show you some tips from the professionals who make blown film extruder screw barrels.

You might think that as long as the screw barrel is made from 38CrMoALA, there will be no quality problems. It’s not true. It’s not just about the base material, it’s also about the structure and design of the screw and barrel. You also have to make sure it’s suitable for the plastic film you’re using. These are a few parameters you need to evaluate the screw barrel’s quality.

01 Select the right screw structure

It takes a lot of care when choosing a screw structure for LDPE, HDPE, PP, PVC, PA, PVDF, and other different materials. For example, the screw for producing LDPE film can’t be applied to produce HDPE film. The screw for producing PE film can’t be applied to make PVC film. Also, PVC and PE screws can’t be used to make PVDF film.

02 Determine the screw L/D ratio

Different products require different screw length-to-diameter ratios. For example, the screw L/D ratio for PVC film should not be too large, while the screw length-diameter ratio for PA film should not be too small. The length-diameter ratio of the blowing LDPE and HDPE film screw should be 28:1 or more, and it should not exceed 30:1. Ideally, the screw should have a Mixing screw structure and a Progressive screw structure. When blowing PP film, the screw ratio of length to diameter needs to be 25:1-28:1, the screw must be mutation type. The mutation area must be placed in a position of great importance, as incorrect design directly affects the result, the mixing head must also be placed on the top of the screw.

03 Anti-wear and anti-corrosion treatment for screw barrels

For the production of finished products from special raw materials, it is sometimes necessary to design a unique screw barrel to meet the requirements of use. Likewise, the screw barrel used in the production of PVDF film products must utilize special alloy steel as the base material. For flexible PVC film products, screw barrels must also get bimetallic alloy treatment to harden their surfaces. They’re for preventing corrosive substances in raw materials from corroding scrrews and barrels and affecting their service life.

04 Select the right screw structure

The shape and structure of the screw determine the quality of the finished product. For typical examples, PE film is generally applied to the progressive type screw, PP film is suitable for applying to the mutation type screw. Often accompanied by a mixing screw in order to meet plasticisation requirements.

05 Select the right barrel structure

The design of the barrel feed inlet also affects the rate of feed. For example, blown film extruder barrels can be smooth bore barrels, this type of barrel is more common. There are also barrels that use a forced feed system. It’s an inlet with grooves on the inside wall of the barrel. The grooved feed barrel gets more efficient, the melt pressure in the barrel climbs up, and the extrusion output rises up. To get a higher grade of feed rate, there’s also an upgraded forced feeder barrel with a cooling water jacket.

Summary

There are a few key things you need to consider when choosing a screw barrel for blown film extrusion. In blown film extrusion screw barrels, it’s not just about a high-quality base material. The screw barrel’s design, structure, L/D ratio, and corrosion resistance are all key factors.

You can contact us for the latest upgrade options and the most competitive quotation for your plastic blown film extruder screw barrel.

YOU MAY ALSO LIKE

| Blown Film Extruder Screw Barrel ↗ Get details & quote for blown film extruder screw barrel. Bimetallic alloy anti-wear screw barrels for better plastic film making at HUACHEN… |

About us

HUACHEN Screw has been an outstanding customized blown film extruder screw barrel manufacturer in Zhoushan Jintang since 1993. With many years of experience designing and processing plastic machinery replacement parts, HUACHEN Screw can provide its customers with a wide range of services, including drawing rebuilding, design, modification, and customized screw barrel. Our company has also successfully exported and supplied screw barrels to customers worldwide. >>Learn more about our company

RELATED CONTENT ABOUT SCREW BARREL

- High-performance PVC Screw Barrel for Efficient Extrusion

- Durable Conical Twin Screw Barrel for Precision PVC Pipe Production

- High-Speed Screw Barrel for Increased Extrusion Efficiency

- Super Wear-Resistant Bimetallic Alloy Coating Screw Barrel for High Output Extruders

- High-Precision Parallel Twin Screw Barrel for Extrusion Excellence

- Top Quality Single Screw Barrels for Plastic Extrusion Applications

- High-quality Extruder Screw Barrel for Reliable Performance

- Efficient Plastic Extrusion Screw Barrel for Superior Output

conical twin screw barrel extruder screw barrel extrusion screw barrel Foam sheet processing high speed screw barrel HUACHEN SCREW news injection screw barrel parallel twin screw barrel pa screw barrel pe making formula pe screw barrel plastic fiber processing plastic fibre screw barrel Plastic film making screw barrel plastic pipe processing Plastic profile processing Plastic raw material knowledge pp screw barrel PVC making formula pvc screw barrel related parts for screw barrel screw barrel engineering work screw barrel knowledge single screw barrel twin screw barrel

;