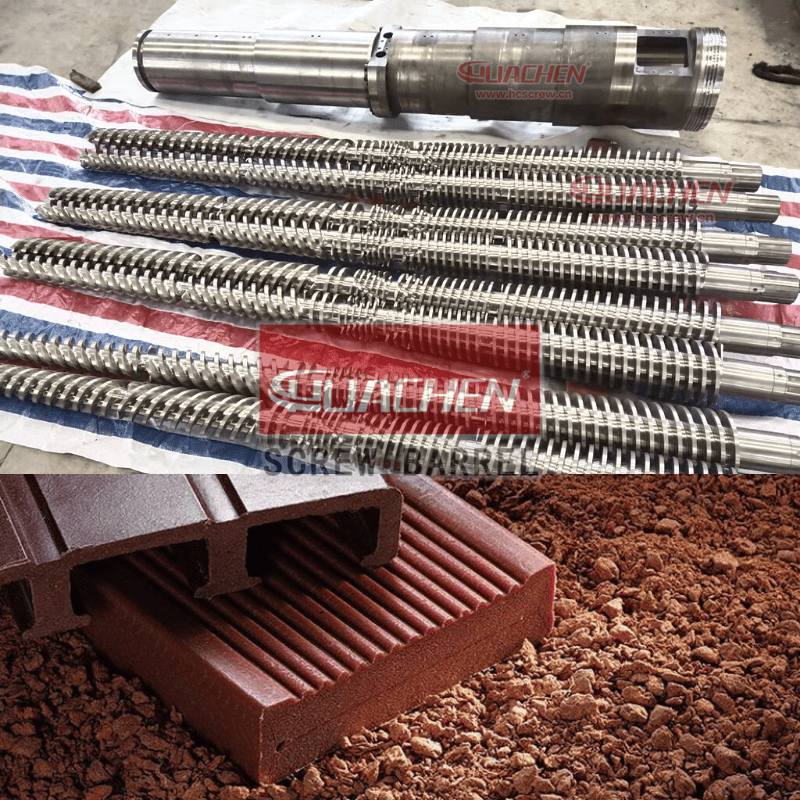

WPC Wood Plastic Composite Extruder Conical Twin Screw Barrel

● PVC / PE / WPC, virgin or recycled materials, foam extrusion process

● Filler ratio of 200-300%, and greater than 300%.

● Min. Order (MOQ): 2 conical screws + 1 barrel

● Based material: Premium 38CrMoAlA tempered and nitrided, SKD11

● Anti-wear solution: SKD sleeve fitted barrel + bimetallic screw, bimetallic barrel + bimetallic screw, chrome coating screw, ceramic alloy screw

You Need Better Conical Twin Screw Barrel at Good Price!

- Product Detail

Optimize Your WPC Production with HUACHEN’s Conical Twin Screw Barrels

Upgrade to the Best in the Industry!

Discover how HUACHEN’s innovative conical twin screw barrels can revolutionize your WPC wood plastic composite extrusion process. Our cutting-edge technology ensures exceptional performance, improved efficiency, and significant cost savings.

Why Choose HUACHEN’s Conical Twin Screw Barrels?

- 1. Superior Design for WPC: Our conical twin screw barrels feature a specialized compression ratio and thread design tailored for WPC products. This ensures excellent plasticizing capacity, allowing for the efficient production of wood plastic profiles, foam sheets, and flooring.

- 2. High Conveying Efficiency: Designed for low shear and high conveying, our screws enable the production of thick or solid WPC sheets with outstanding plasticization, enhancing output and quality.

- 3. Venting Ports for Quality: Equipped with vent ports, our barrels prevent moisture buildup in WPC raw materials, resulting in products with improved surface gloss and hardness.

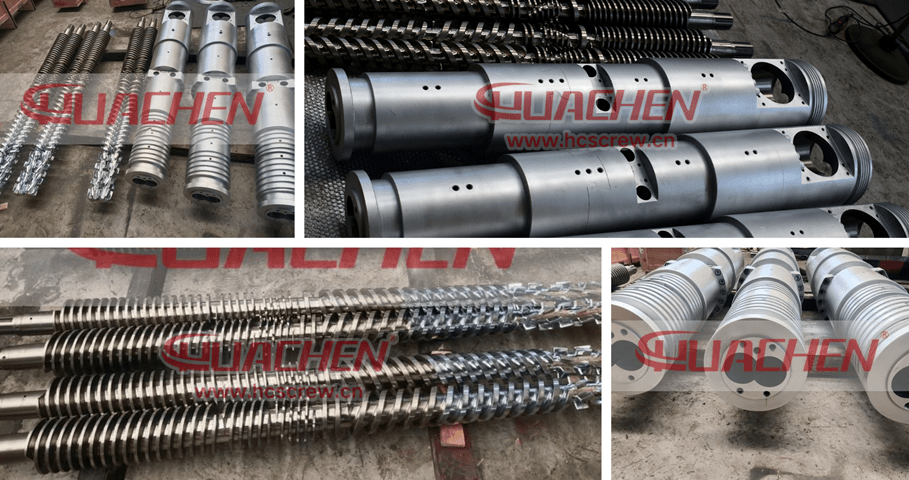

- 4. Enhanced Durability: Constructed from high-quality 38CrMoAlA steel, our screw barrels undergo strict tempering and nitriding processes, providing superior wear and corrosion resistance for extended service life.

- 5. Easy Installation and Versatility: Available in standard and high-efficiency models (65, 80, 92, and more), our screw barrels are designed with standard assembly dimensions for seamless integration. Our designs are fine-tuned to meet regional and country-specific requirements.

Key Features

- 1. Specialized Compression Ratio and Screw Thread Design: Tailored for WPC wood plastic products, supporting the extrusion of wood plastic profiles, foam boards, and flooring.

- 2. Low Shear and High Conveying: Enables the production of thick or solid WPC sheets with excellent plasticizing capacity.

- 3. Venting Port: Prevents moisture buildup, enhancing the surface gloss and hardness of WPC products.

- 4. High-Quality Materials: Made from 38CrMoAlA steel, tempered and nitrided for superior hardness and corrosion resistance.

- 5. Precision Machining: Ensures consistent extrusion performance and smooth surfaces on screws and barrels to prevent material buildup.

Levels of Anti-Wear Solutions

- 1. Bimetallic Alloy Screw Barrel: Tungsten carbide overlay on wearable parts for extended service life, up to 1.5 times longer.

- 2. Hard Chrome Plating: Provides an additional protective layer on the screw.

- 3. Ceramic Coating Alloy Screw: Offers enhanced durability.

- 4. SKD Sleeve Fitted Barrel: Barrel with SKD sleeves fitted, sleeve length extends to barrel venting port.

Application

- -WPC sheet or board conical twin screw extruder

- -WPC profile conical twin screw extruder

- -WPC wall panel and siding conical twin screw extruder

- -WPC foam sheet or board conical twin screw extruder

- -WPC composite flooring conical twin screw extruder

- -WPC decorative sheet conical twin screw extruder

Model Specifications

| Model | Screw speed (rpm) | Motor (kW) | Capacity (kg/h) | Screw length (mm) | Barrel length (mm) | Weight (kg) | Package dimension (m) |

|---|---|---|---|---|---|---|---|

| HCZS65/132 | 34.7 | 37 | 380 | 1701 | 1480 | 410 | 1.8*0.3*0.4 |

| HCZS80/156 | 34.7 | 55 | 500 | 2116 | 1850 | 775 | 2.2*0.4*0.5 |

| HCZS92/188 | 34.7 | 110 | 800 | 2805 | 2520 | 1500 | 3.0*0.5*0.6 |

Premium Materials and Parameters

Our conical twin screw barrels are made with high-quality materials and precision engineering to ensure long-lasting performance:

- 1. Core Materials: 38CrMoAlA, UNS K24065, SACM645, 41CrAlMo7-10, SKD11

- 2. Plasma Nitriding Layer: 0.6-0.8 mm for enhanced surface hardness

- 3. Nitriding Surface Hardness: HV1000-1100 for robust performance

- 4. Nitriding Brittleness: Less than Grade 1, balancing hardness and toughness

- 5. Surface Roughness: Ra 0.4μm for smooth material flow

- 6. Screw Linearity: ≤0.015 mm for precise operation

- 7. Alloy Surface Hardness: HRC≥61 for superior wear resistance

- 8. Alloy Depth: 6-8 mm for long-lasting durability

- 9. SKD Sleeve Surface Hardness: HRC≥62 for excellent wear resistance

- 10. SKD Sleeve Thickness: 6-10 mm

For detailed parameters, visit our WPC Wood Plastic Composite Extruder Conical Twin Screw Barrel Parameters.

Fast Production Times

- –Ready Stock Models: Available within 7 days.

- –Custom-Made Models: Available within 30 days, depending on part complexity.

How to Order from HUACHEN Screw Barrel

Ready to upgrade your production with HUACHEN’s conical twin screw barrels? Follow our simple Step-by-Step Guide to Order from HUACHEN Screw:

- 1. Contact Us: Reach out to our sales team via email or phone.

- 2. Specify Requirements: Provide detailed specifications and requirements for your project.

- 3. Receive a Quote: Our team will provide a customized quote based on your needs.

- 4. Place an Order: Confirm the order and provide necessary payment details.

- 5. Production and Delivery: We will manufacture your order and arrange for timely delivery.

For inquiries or more information, please contact us.

About HUACHEN Screw Barrel

Since 1993, HUACHEN Screw Barrel has been a leading manufacturer of conical twin screw barrels in Zhoushan Jintang. As a pioneer in designing and processing conical twin screw extruder spare parts, we offer a wide range of services, including drawing rebuilding, design, modification, and customized screw barrels. Our products are trusted globally for their durability and efficiency.

To learn more about our company and services, please visit our About Us page.